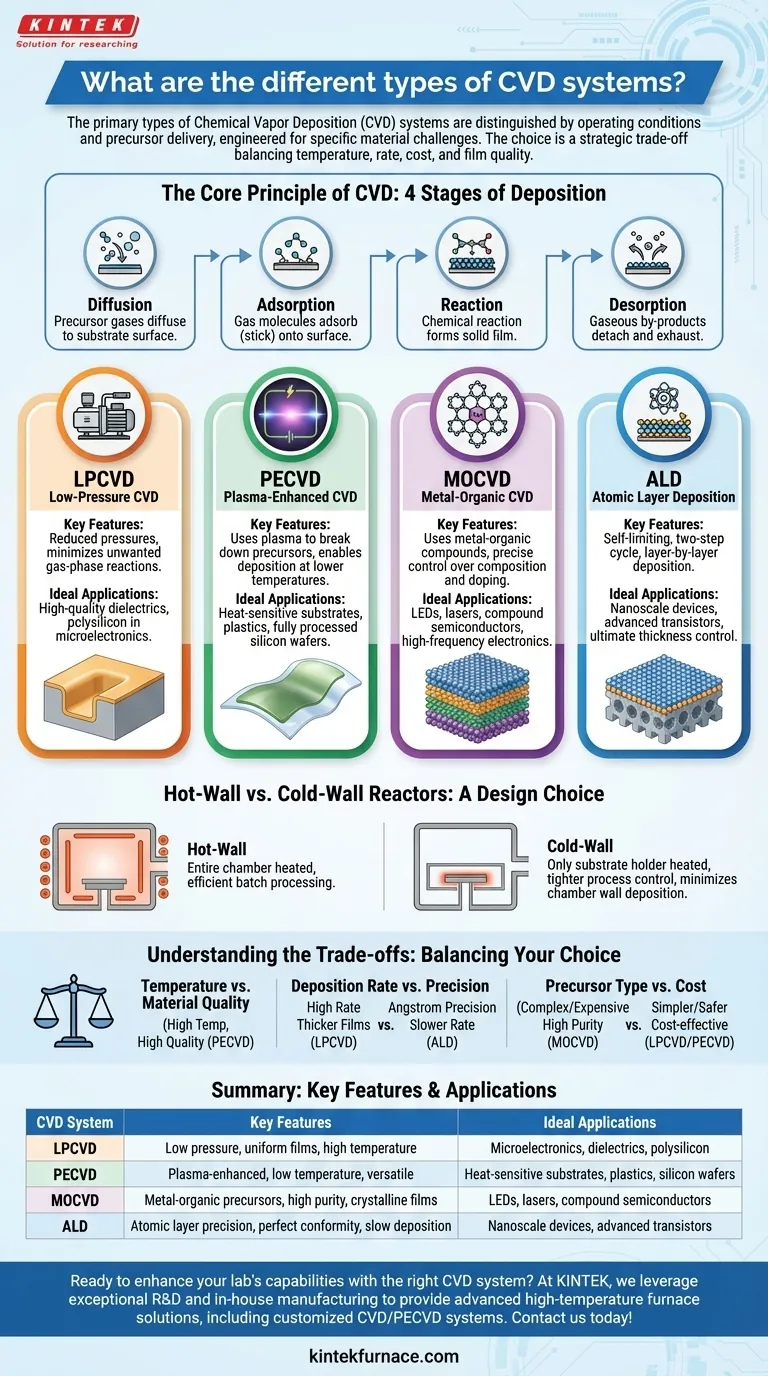

The primary types of Chemical Vapor Deposition (CVD) systems are distinguished by their operating conditions and precursor delivery methods. The most common variations include Low-Pressure CVD (LPCVD), Plasma-Enhanced CVD (PECVD), Metal-Organic CVD (MOCVD), and Atomic Layer Deposition (ALD), each engineered to solve specific material deposition challenges related to temperature, film quality, and precision.

The choice of a CVD system is not about finding the "best" one, but about making a strategic trade-off. You must balance the need for deposition temperature, rate, cost, and the required precision of the final thin film.

The Core Principle of CVD

Before comparing systems, it's crucial to understand the fundamental process. CVD is a technique used to grow a solid, high-purity thin film on a substrate through a series of controlled chemical reactions.

How It Works

The process involves introducing one or more volatile precursor gases into a reaction chamber. These gases decompose or react on a heated substrate surface, leaving behind the desired solid material as a coating.

The Four Stages of Deposition

Every CVD process follows four key steps:

- Diffusion: Precursor gases diffuse through the chamber to the substrate's surface.

- Adsorption: The gas molecules are adsorbed (stick) onto the surface.

- Reaction: A chemical reaction occurs on the surface, forming the solid film.

- Desorption: Gaseous by-products of the reaction detach and are exhausted from the chamber.

Key CVD Systems and Their Purpose

The "different types" of CVD are simply modifications to this core process, optimized for specific outcomes. They primarily differ in pressure, temperature, and the energy source used to drive the reaction.

Low-Pressure CVD (LPCVD)

LPCVD systems operate at reduced pressures. This seemingly simple change significantly reduces unwanted gas-phase reactions and slows the transport of precursors, leading to exceptionally uniform and conformal films over complex topographies. It is a workhorse for depositing high-quality dielectrics and polysilicon in microelectronics.

Plasma-Enhanced CVD (PECVD)

PECVD utilizes an electric field to generate a plasma (an ionized gas). This plasma provides the energy to break down precursor gases, allowing deposition to occur at much lower temperatures than traditional CVD. This is its key advantage, making it essential for depositing films on substrates that cannot withstand high heat, such as plastics or fully processed silicon wafers.

Metal-Organic CVD (MOCVD)

MOCVD uses metal-organic compounds as precursors. These specialized molecules are key to depositing high-purity, single-crystal films, particularly for compound semiconductors used in LEDs, lasers, and high-frequency electronics. The process offers precise control over composition and doping.

Atomic Layer Deposition (ALD)

Often considered a subclass of CVD, ALD is the ultimate in precision. It breaks the deposition into a self-limiting, two-step cycle where precursors are introduced one at a time. This allows for the film to be built up literally one atomic layer at a time, providing unparalleled thickness control and perfect conformity, which is critical for modern, nanoscale transistors.

Hot-Wall vs. Cold-Wall Reactors

This is a fundamental design choice. In a hot-wall reactor, the entire chamber is heated, allowing for efficient batch processing of many substrates at once. In a cold-wall reactor, only the substrate holder is heated, which minimizes deposition on the chamber walls and provides tighter process control, ideal for research and single-wafer manufacturing.

Understanding the Trade-offs

Selecting a CVD system requires a clear understanding of the compromises involved. Each system excels in one area, often at the expense of another.

Temperature vs. Material Quality

Generally, higher temperatures produce higher-quality, denser films with fewer impurities. However, this limits the types of substrates you can use. PECVD solves this by trading thermal energy for plasma energy, enabling good films at low temperatures.

Deposition Rate vs. Precision

Methods like LPCVD offer a good balance of deposition rate and uniformity for thicker films (hundreds of nanometers). However, for angstrom-level precision required in advanced logic devices, the much slower, layer-by-layer approach of ALD is non-negotiable.

Precursor Type and Cost

The precursors themselves introduce trade-offs. MOCVD precursors can be highly toxic, flammable, and expensive, but they are necessary for producing certain high-performance crystalline materials. Simpler precursors used in LPCVD or PECVD are often safer and more cost-effective.

Choosing the Right CVD Method for Your Application

Your choice should be dictated entirely by your end goal and material constraints.

- If your primary focus is high-throughput production of uniform films: LPCVD is often the most cost-effective and reliable choice for materials like silicon nitride or polysilicon.

- If your primary focus is depositing films on heat-sensitive substrates: PECVD is the definitive solution, as it decouples the deposition reaction from thermal requirements.

- If your primary focus is creating high-purity crystalline layers for optoelectronics: MOCVD is the industry standard and provides the necessary compositional control.

- If your primary focus is ultimate thickness control and perfect conformity for nanoscale devices: ALD is the only technology that can deliver the required atomic-level precision.

By understanding these fundamental differences, you can select the deposition technology that directly enables your specific material engineering goal.

Summary Table:

| CVD System Type | Key Features | Ideal Applications |

|---|---|---|

| LPCVD | Low pressure, uniform films, high temperature | Microelectronics, dielectrics, polysilicon |

| PECVD | Plasma-enhanced, low temperature, versatile | Heat-sensitive substrates, plastics, silicon wafers |

| MOCVD | Metal-organic precursors, high purity, crystalline films | LEDs, lasers, compound semiconductors |

| ALD | Atomic layer precision, perfect conformity, slow deposition | Nanoscale devices, advanced transistors |

Ready to enhance your lab's capabilities with the right CVD system? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can drive your research forward!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does Thermal Chemical Vapor Deposition work? Unlock High-Purity Thin Film Deposition

- How does a CVD machine work? Master the Technology for High-Quality Thin Film Deposition

- Is PVD the same as CVD? Understanding the Physical vs. Chemical Deposition Difference

- What are the advantages of using a CVD tube furnace for preparing gate dielectrics? Achieve High-Quality Thin Films for Transistors

- What are the main disadvantages of Chemical Vapor Deposition (CVD)? High Costs, Complex Control, and Safety Risks

- Why is a high vacuum magnetron sputtering system required for NiO layers? Ensure Chemical Purity and Conductivity

- What are common precursors used in CVD? Discover Key Types for Superior Thin Films

- What are the two primary methods for depositing thin films? Master PVD and CVD for Your Lab