Historically, the most common and foundational use of aluminum films in semiconductor devices is to create the electrical interconnects, or "wiring," that connect the millions or billions of transistors on a chip. These thin metal pathways are responsible for distributing power and transmitting data signals, forming the fundamental circulatory system of the integrated circuit.

While once the default choice for all on-chip wiring, aluminum's role has evolved. Its story reveals a core engineering trade-off between manufacturing simplicity and the physical limits of materials at the nanoscale.

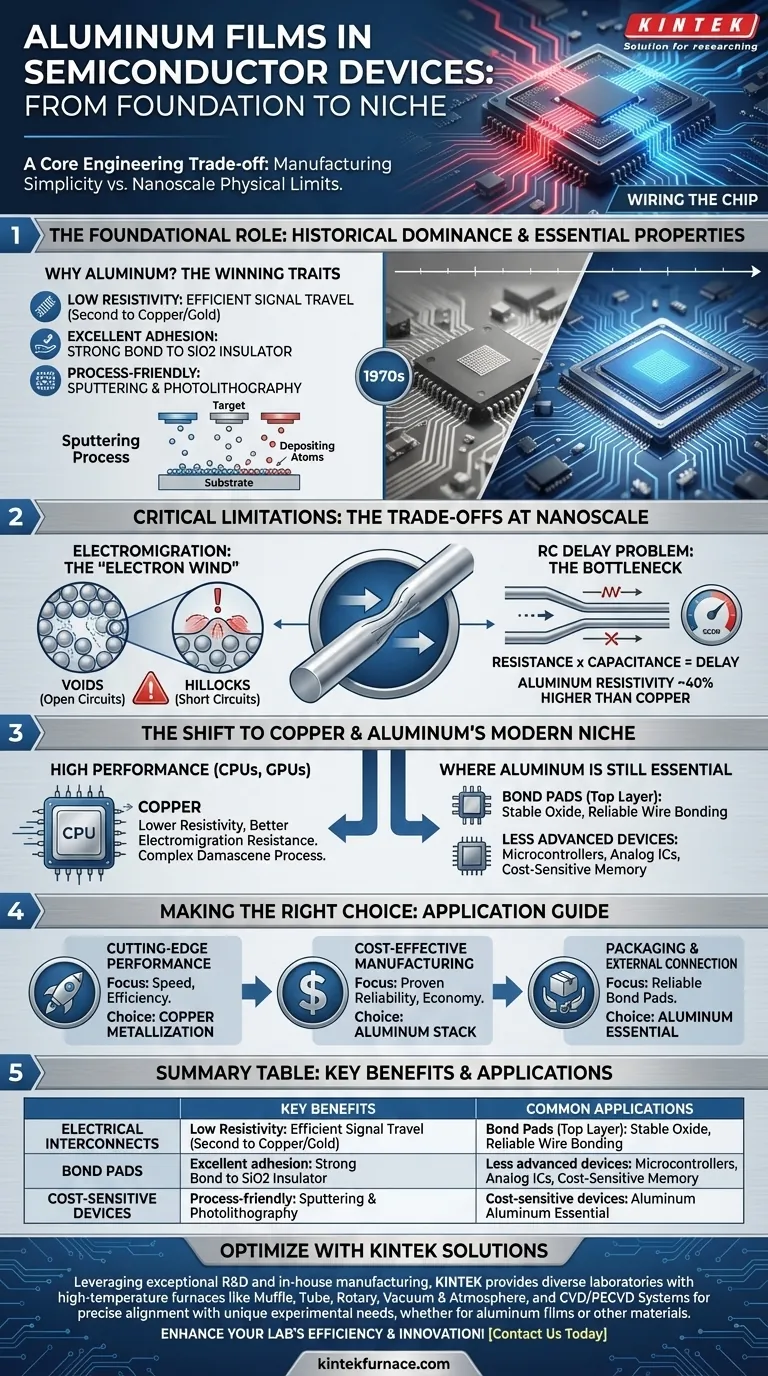

The Foundational Role of Aluminum as an Interconnect

For decades, aluminum was the undisputed material of choice for metallization in semiconductor fabrication. This was not by accident; it possesses a unique combination of properties that made it nearly perfect for the task in the early eras of chip manufacturing.

Why Aluminum? The Essential Properties

Aluminum offers low electrical resistivity, second only to more complex metals like copper and gold. This ensures that electrical signals can travel through the chip's wiring with minimal loss and delay.

Crucially, it also demonstrates excellent adhesion to silicon dioxide (SiO2), which is the primary insulating material used to separate the different layers of wiring. This strong bond prevents the metal layers from peeling or delaminating during manufacturing or operation.

A Process-Friendly Material

Fabricating circuits with aluminum is a relatively straightforward and well-understood process. It can be easily deposited in thin, uniform films using a technique called sputtering.

Once deposited, these films can be precisely patterned into wires using photolithography and dry etching, allowing for the creation of incredibly complex circuit layouts.

Understanding the Trade-offs: Critical Limitations

As transistors shrank and clock speeds increased, the inherent physical limitations of aluminum became critical roadblocks to further performance gains, leading to significant reliability challenges.

The Primary Failure: Electromigration

The most significant weakness of aluminum is its susceptibility to electromigration. At the high current densities found in modern chips, the flow of electrons can physically push aluminum atoms along the wire.

This "electron wind" gradually creates voids (gaps) in some areas and hillocks (pile-ups) in others. A large enough void will cause an open circuit, while a hillock can create a short circuit to an adjacent wire, both resulting in chip failure.

The RC Delay Problem

As interconnects become thinner and more densely packed, their resistance (R) and the capacitance (C) between them increase. The product of these two values, the RC delay, dictates how quickly a signal can travel.

Aluminum's resistivity, while low, is about 40% higher than that of copper. This higher resistance became a primary bottleneck, limiting the maximum speed at which a chip could operate.

The Shift to Copper and Aluminum's Modern Niche

These limitations forced the industry to transition to copper for high-performance interconnects, a major technological shift that began in the late 1990s.

Copper's Ascendancy in High Performance

Copper has lower resistivity and significantly better resistance to electromigration. However, it is much more difficult to process and requires barrier layers to prevent it from diffusing into and poisoning the silicon. This led to the development of the complex Damascene process.

Where Aluminum Is Still Essential

Despite the shift to copper for the finest layers of wiring in CPUs and GPUs, aluminum has not disappeared. It remains the material of choice in several key areas.

Its most prominent modern use is for the thick, top-level metal layers and bond pads. These are the connection points where the chip is physically wired to the package. Aluminum forms a stable, self-passivating oxide layer that is ideal for reliable wire bonding. It is also still widely used in less advanced or more cost-sensitive devices like microcontrollers, analog ICs, and some memory and power semiconductor devices.

Making the Right Choice for Your Application

The choice between aluminum and copper is dictated entirely by the performance requirements, cost constraints, and specific function within the device.

- If your primary focus is cutting-edge performance (CPUs, GPUs): Copper metallization is the non-negotiable standard for performance-critical interconnects due to its superior conductivity.

- If your primary focus is cost-effective manufacturing for less demanding chips (microcontrollers, analog): Aluminum remains a proven, reliable, and economical choice for the entire interconnect stack.

- If your primary focus is packaging and external connection: Aluminum is the essential material for top-level bond pads across nearly all chip types to ensure a reliable connection to the outside world.

Understanding the historic role and modern niche of aluminum provides a clear perspective on the material science trade-offs that continue to drive semiconductor innovation.

Summary Table:

| Use Case | Key Benefits | Common Applications |

|---|---|---|

| Electrical Interconnects | Low resistivity, excellent adhesion to SiO2, process-friendly | Early chips, microcontrollers, analog ICs |

| Bond Pads | Stable oxide layer, reliable for wire bonding | Top-level connections in nearly all chip types |

| Cost-Sensitive Devices | Economical, proven reliability | Less advanced ICs, power semiconductors |

Optimize your semiconductor processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for developing aluminum films or other materials. Contact us today to enhance your lab's efficiency and innovation!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are gas barrier films, and how is PECVD involved in their creation? Discover Advanced Packaging Solutions

- What is the difference between PVD and PECVD? Choose the Right Thin-Film Coating Technology

- What is the role of temperature in PECVD? Optimize Film Quality and Substrate Protection

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab