In short, a tube furnace is used for a wide range of high-temperature thermal processes in laboratories, especially those requiring a precisely controlled atmosphere. Common applications include heat treatments like annealing and sintering, the synthesis of new materials, and purification processes that must be performed under a vacuum or in the presence of a specific gas. Its design is uniquely suited for processing small, uniform samples with high precision.

The key to understanding a tube furnace is to see it not just as a high-temperature oven, but as a controlled micro-environment. Its true value lies in its ability to isolate a sample from the air, allowing researchers to precisely manage both temperature and atmosphere, which is a requirement for many advanced material science applications.

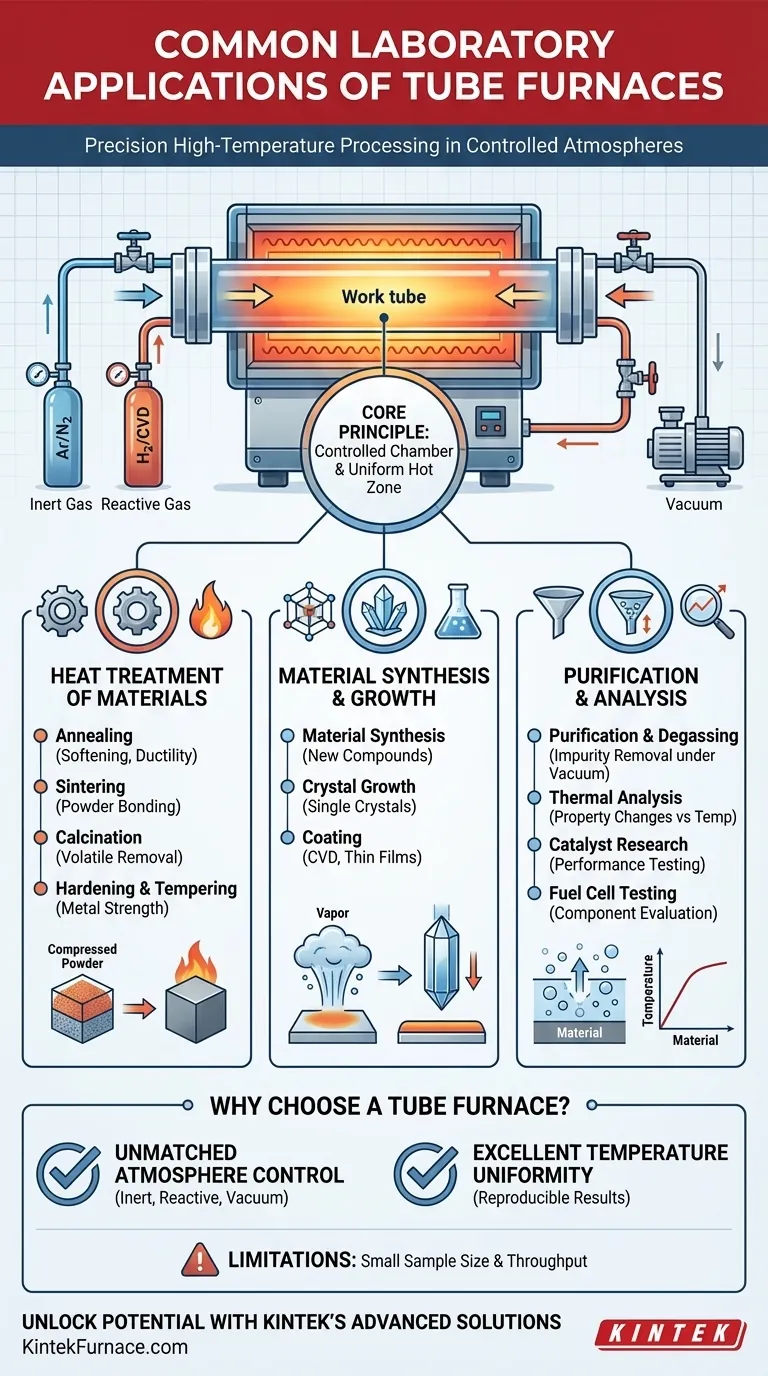

The Core Principle: A Controlled Chamber for Thermal Processing

A tube furnace's applications are a direct result of its fundamental design: a cylindrical heating chamber. This simple geometry is the key to its versatility in a research and development setting.

The Critical Role of Atmosphere Control

The defining feature of a tube furnace is its ability to maintain a controlled atmosphere. The work tube can be sealed at both ends, allowing for several conditions:

- Inert Gas: Pumping in a gas like argon or nitrogen prevents oxidation and other unwanted reactions with air.

- Reactive Gas: Introducing specific gases (e.g., hydrogen, hydrocarbons) allows for controlled chemical reactions on the sample's surface, such as in chemical vapor deposition (CVD).

- Vacuum: Removing the atmosphere entirely is necessary for processes like degassing or for protecting extremely sensitive materials.

This level of atmospheric control is impossible to achieve in a standard box or muffle furnace.

Precision Temperature Uniformity

The cylindrical heating elements surrounding the tube create a highly uniform "hot zone" in the center. This ensures that the entire sample experiences the same temperature, which is critical for achieving consistent and repeatable experimental results.

Key Application Categories

While the list of uses is long, most applications fall into a few primary categories. Understanding these categories is more useful than memorizing a list of individual processes.

Heat Treatment of Materials

This involves heating and cooling solid materials to alter their physical and chemical properties. A controlled atmosphere is often essential to prevent oxidation at high temperatures.

- Annealing: Reduces hardness and increases the ductility of a material.

- Sintering: Heats a compressed powder to bond particles together, forming a solid object without melting.

- Calcination: Heats a material to drive off volatile substances like water or carbon dioxide.

- Hardening & Tempering: Specific heat treatments used to increase the hardness and toughness of metals.

Material Synthesis and Growth

This category involves creating new materials or crystalline structures that would be impossible to form in open air.

- Material Synthesis: Creating novel compounds by reacting precursors at high temperatures.

- Crystal Growth: Carefully growing single, highly-ordered crystals from a melt or vapor phase.

- Coating: Applying thin films to a substrate, a process often done via chemical vapor deposition (CVD), which requires a controlled flow of reactive gases.

Purification and Analysis

These applications use heat to prepare, clean, or study a sample.

- Purification & Degassing: Using heat under a vacuum to remove impurities or trapped gases from a material.

- Thermal Analysis: Studying how a material's properties change as a function of temperature.

- Catalyst Research: Testing the performance and durability of catalytic materials under specific gas flows and temperatures.

- Fuel Cell Testing: Simulating the high-temperature operating conditions of fuel cells to evaluate component materials.

Understanding the Trade-offs: When to Choose a Tube Furnace

No single piece of equipment is perfect for every job. Knowing the limitations of a tube furnace is as important as knowing its strengths.

Advantage: Unmatched Atmosphere Control

As stated, this is the primary reason to choose a tube furnace. If your process requires a vacuum, an inert atmosphere, or a reactive gas flow, a tube furnace is the default choice.

Advantage: Excellent Temperature Uniformity

For small, uniform samples, the thermal uniformity within the hot zone is exceptional. This leads to highly reproducible results, which is vital for research.

Limitation: Sample Size and Throughput

Tube furnaces are inherently limited by the diameter of the work tube. They are designed for small samples and low-throughput operations, making them ideal for R&D but impractical for large-scale production. A box furnace is better for heating many items or a single, bulky object in air.

Limitation: Geometric Constraints

The sample must physically fit inside the tube. This makes them unsuitable for processing large, flat, or irregularly shaped objects that could be easily placed on the floor of a box furnace.

Making the Right Choice for Your Goal

Your decision should be based on the fundamental requirements of your thermal process.

- If your primary focus is modifying existing materials (e.g., metals, ceramics): A tube furnace is ideal for heat treatments like annealing or sintering where preventing oxidation with an inert gas is critical.

- If your primary focus is creating new materials or thin films: The controlled gas environment of a tube furnace is essential for synthesis methods like chemical vapor deposition (CVD) or for growing pure crystals.

- If your primary focus is simply heating large or bulky items in air: A box or muffle furnace is almost always a more practical and cost-effective solution.

Understanding that a tube furnace's power comes from its environmental control is the key to unlocking its full potential in your laboratory.

Summary Table:

| Application Category | Key Processes | Primary Benefits |

|---|---|---|

| Heat Treatment | Annealing, Sintering, Calcination | Controlled atmosphere prevents oxidation, uniform heating |

| Material Synthesis | CVD, Crystal Growth, Coating | Enables reactions in inert or reactive gases |

| Purification & Analysis | Degassing, Thermal Analysis, Catalyst Testing | Vacuum or gas flow for impurity removal and study |

Unlock the full potential of your laboratory with KINTEK's advanced tube furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces tailored to your needs. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're conducting heat treatments, material synthesis, or purification processes, KINTEK delivers reliable performance and unmatched atmosphere control. Contact us today to discuss how our solutions can enhance your research efficiency and outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab