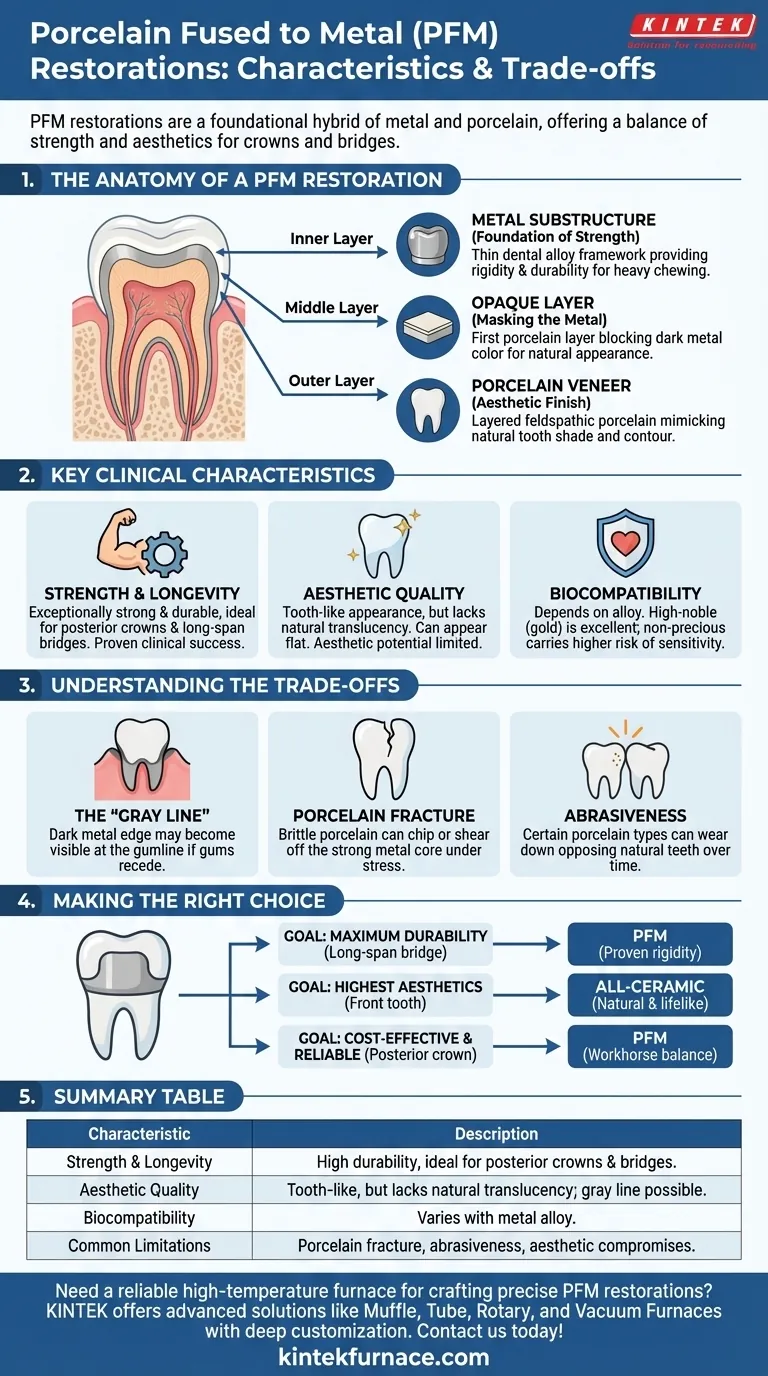

Porcelain Fused to Metal (PFM) restorations are a foundational technology in restorative dentistry, representing a hybrid approach to crown and bridge work. They consist of a metal alloy substructure, which provides strength and a precise fit, covered by a layer of veneering porcelain that is fused to the metal to provide tooth-like aesthetics. This combination aims to leverage the best qualities of both materials.

PFM restorations have long been the workhorse of dentistry, offering a predictable and durable solution that balances strength with cosmetic appearance. However, their defining characteristic is this very compromise; they are rarely the strongest or the most aesthetic option available today, but they provide a reliable middle ground.

The Anatomy of a PFM Restoration

Understanding a PFM's performance begins with its layered structure. Each layer serves a distinct purpose, and their interaction defines the restoration's clinical characteristics.

The Metal Substructure: The Foundation of Strength

The core of a PFM is a thin, thimble-like coping made of a dental alloy. This metal framework is what provides the restoration with its rigidity and durability, making it resistant to the heavy forces of chewing.

The type of metal used can vary, from precious alloys (high gold content) to semi-precious and non-precious alloys (like cobalt-chromium), which can impact biocompatibility and cost.

The Opaque Layer: Masking the Metal

A critical, often overlooked layer is the opaque porcelain. This is the first layer of porcelain applied directly to the metal.

Its sole function is to block the dark, metallic color of the substructure from showing through. Without this layer, the final restoration would appear gray and unnatural.

The Porcelain Veneer: Creating the Aesthetic Finish

Finally, layers of feldspathic porcelain are built up over the opaque layer and fired in a high-heat oven. A skilled dental technician can layer different shades and translucencies of porcelain to mimic the appearance of a natural tooth. This outer layer is what provides the final color and contour.

Key Clinical Characteristics

The layered design of a PFM directly translates to its primary strengths and weaknesses in a clinical setting.

Strength and Longevity

The metal substructure makes PFMs exceptionally strong and durable. They have a long track record of clinical success, particularly for single crowns and multi-unit bridges in the posterior of the mouth where chewing forces are greatest.

Aesthetic Quality

While PFMs are designed to look like teeth, their aesthetics are inherently limited. Because light cannot pass through the metal and opaque core, they lack the natural vitality and translucency of an all-ceramic restoration. They can sometimes appear "flat" or chalky, especially in certain lighting.

Biocompatibility

The biocompatibility of a PFM restoration is largely determined by the alloy used in its substructure. High-noble (gold) alloys are extremely biocompatible and kind to the gum tissue. Non-precious alloys are also safe for most patients but carry a slightly higher risk of allergic sensitivity.

Understanding the Trade-offs and Limitations

No dental material is perfect. The hybrid nature of PFMs introduces specific compromises that are crucial to understand when comparing them to other options.

The "Gray Line" at the Gumline

The most well-known aesthetic drawback of a PFM is the potential for a dark or gray line to appear at the gingival margin (the gumline). This occurs when the gums recede even slightly, exposing the dark metal edge of the crown.

Potential for Porcelain Fracture

While the metal core is strong, the porcelain layered over it can be brittle. Under specific types of force, the porcelain can chip or shear off the underlying metal. This is a common mode of failure for PFM restorations.

Abrasiveness to Opposing Teeth

The type of porcelain used on PFMs can be more abrasive than natural tooth enamel or newer ceramic materials. Over many years, a PFM crown can cause wear on the opposing natural tooth it chews against.

Making the Right Choice for Your Goal

Selecting a restorative material requires matching its characteristics to the clinical need and the patient's priorities.

- If your primary focus is maximum durability for a long-span bridge: PFM remains a highly predictable and strong option due to the proven rigidity of its metal framework.

- If your primary focus is the highest level of aesthetics for a front tooth: An all-ceramic restoration (like lithium disilicate or zirconia) will almost always provide a more natural and lifelike result.

- If your primary focus is a cost-effective and reliable posterior crown: PFM offers a proven balance of strength, acceptable aesthetics, and longevity, making it an excellent workhorse solution.

By understanding the distinct blend of strength and compromise inherent in PFM restorations, you can make a more informed decision about the ideal material for your specific goals.

Summary Table:

| Characteristic | Description |

|---|---|

| Strength & Longevity | Metal substructure provides high durability, ideal for posterior crowns and bridges. |

| Aesthetic Quality | Porcelain veneer offers tooth-like appearance but lacks natural translucency; may show gray line. |

| Biocompatibility | Varies with metal alloy (e.g., gold is highly biocompatible, non-precious may cause sensitivity). |

| Common Limitations | Porcelain can fracture, may abrade opposing teeth, and aesthetic compromises exist. |

Need a reliable high-temperature furnace for crafting precise PFM restorations? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor our products to meet your unique experimental and production needs. Contact us today to enhance your lab's efficiency and achieve superior results!

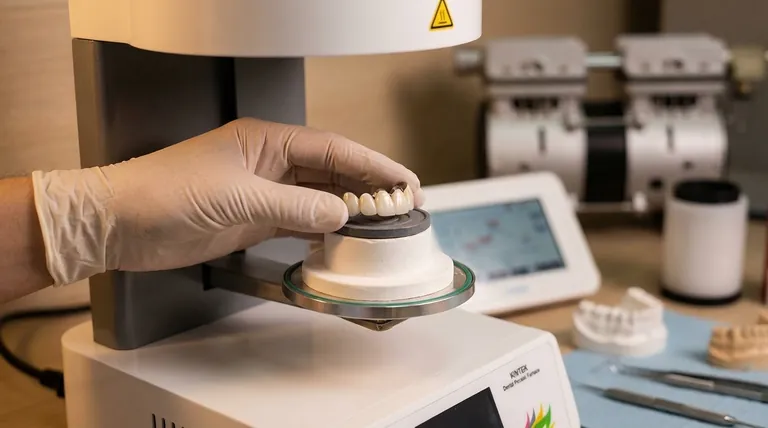

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique