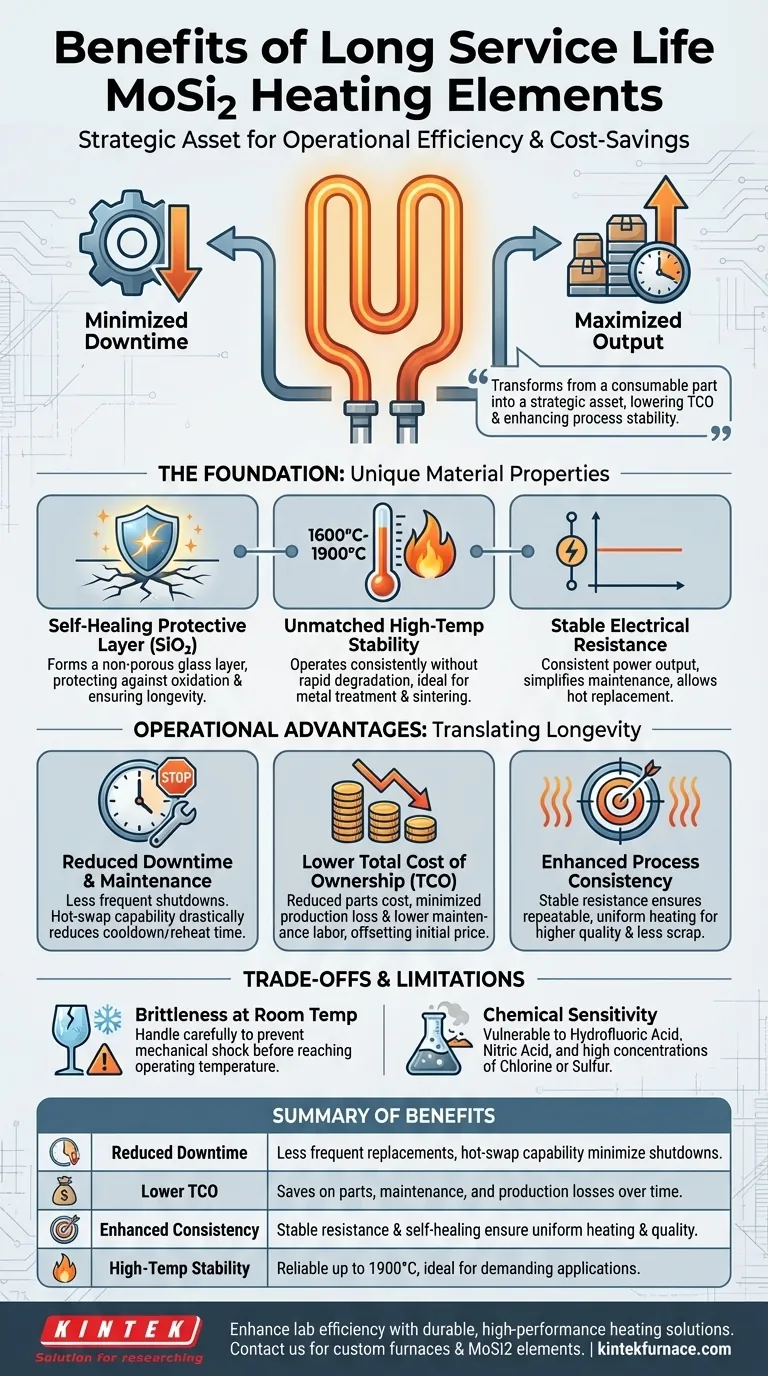

At its core, the long service life of Molybdenum Disilicide (MoSi₂) heating elements translates directly into significant operational and financial advantages. The primary benefits are a drastic reduction in the frequency and cost of element replacement, which in turn minimizes furnace downtime and maximizes production output.

The true value of a MoSi₂ element's long life is not just its durability, but its ability to provide predictable, reliable high-temperature performance. This transforms the heating element from a consumable part into a strategic asset that lowers the total cost of ownership and enhances process stability.

The Foundation of Longevity: Unique Material Properties

The extended lifespan of MoSi₂ elements is not an accident; it is the direct result of their unique chemical and physical properties at extreme temperatures. Understanding these properties is key to appreciating their value.

A Self-Healing Protective Layer

When heated in an oxygen-containing atmosphere, MoSi₂ elements form a thin, non-porous layer of pure silica glass (SiO₂). This layer is the key to their longevity.

If the element is damaged by physical or chemical impact, this silica layer will "heal" itself by re-forming over the exposed area, providing exceptional protection against further oxidation and ensuring a long, stable operational life.

Unmatched High-Temperature Stability

MoSi₂ elements are designed to operate consistently at extreme temperatures, typically between 1600°C and 1700°C, with some grades capable of reaching 1900°C.

Unlike many other metallic elements, they do not soften, melt, or degrade rapidly at these temperatures, making them the standard for demanding applications like metal heat treatment, ceramic sintering, and laboratory furnaces.

Stable Electrical Resistance Over Time

A key feature of MoSi₂ is its stable resistance throughout its service life. This stability is critical for consistent power output and temperature control.

This allows for the connection of new elements in series with older ones without causing imbalances in the system, simplifying maintenance and extending the useful life of the entire heating array.

Translating Longevity into Operational Advantages

The material science of MoSi₂ elements provides tangible benefits that impact an organization's bottom line and operational efficiency.

Reduced Downtime and Maintenance

The simple fact that these elements last longer means furnaces are shut down for maintenance far less frequently. This directly increases available production time.

Furthermore, many MoSi₂ elements can be replaced while the furnace is still hot, drastically reducing the downtime associated with a complete cooldown and reheat cycle.

Lower Total Cost of Ownership (TCO)

While the initial purchase price may be higher than some alternatives, the TCO is often significantly lower.

This calculation includes the reduced direct cost of replacement parts over several years and, more importantly, the indirect savings from minimized production losses and lower maintenance labor costs.

Enhanced Process Consistency

For high-precision thermal processes, consistency is paramount. The stable resistance and slow aging characteristics of MoSi₂ ensure a highly repeatable and uniform heating environment.

This leads to higher product quality, less scrap, and more predictable outcomes in sensitive applications. Their ability to handle rapid thermal cycling without degradation further enhances their reliability.

Understanding the Trade-offs and Limitations

To make an informed decision, it's crucial to recognize the specific conditions and handling requirements for MoSi₂ elements.

Brittleness at Room Temperature

Like many high-performance ceramics, MoSi₂ elements are hard but brittle at low temperatures. They require careful handling and installation to prevent mechanical shock or fracture before they reach their operating temperature.

Chemical Sensitivity

While highly resistant to most atmospheres, they are vulnerable to certain chemicals. MoSi₂ elements will be attacked and dissolved by hydrofluoric acid and nitric acid, and performance can be impacted by atmospheres containing high concentrations of chlorine or sulfur.

Making the Right Choice for Your Application

Selecting a heating element should be based on your primary operational goal.

- If your primary focus is maximizing uptime and production output: The combination of an inherently long lifespan and the ability to perform hot replacements makes MoSi₂ the superior choice for minimizing both planned and unplanned downtime.

- If your primary focus is lowering the total cost of ownership: Look beyond the initial purchase price. The durability of MoSi₂ leads to substantial long-term savings in replacement parts, maintenance labor, and preserved production revenue.

- If your primary focus is process stability at extreme temperatures: The self-healing silica layer and stable electrical resistance of MoSi₂ provide the unparalleled consistency required for high-value, temperature-sensitive manufacturing.

Ultimately, choosing MoSi₂ elements is an investment in long-term operational reliability and efficiency.

Summary Table:

| Benefit | Description |

|---|---|

| Reduced Downtime | Less frequent replacements and hot-swap capability minimize furnace shutdowns. |

| Lower Total Cost of Ownership | Saves on replacement parts, maintenance labor, and production losses over time. |

| Enhanced Process Consistency | Stable resistance and self-healing properties ensure uniform heating and high-quality results. |

| High-Temperature Stability | Operates reliably up to 1900°C, ideal for demanding applications like sintering and heat treatment. |

Ready to enhance your lab's efficiency with durable, high-performance heating solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, reducing downtime and total cost of ownership. Contact us today to discuss how our MoSi2 heating elements can benefit your operations!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights