In modern material processing, a sophisticated control system transforms a rotary furnace from a simple heat source into a precision instrument. These systems provide direct benefits including superior temperature uniformity, optimized processing times, enhanced energy efficiency, and reliable process reproducibility. The result is consistently higher material quality at a lower operational cost.

The core value of a sophisticated control system is not just automation; it is the ability to precisely manage the thermal and mechanical environment within the furnace. This unlocks repeatable, high-quality outcomes and moves your process from an art to a science.

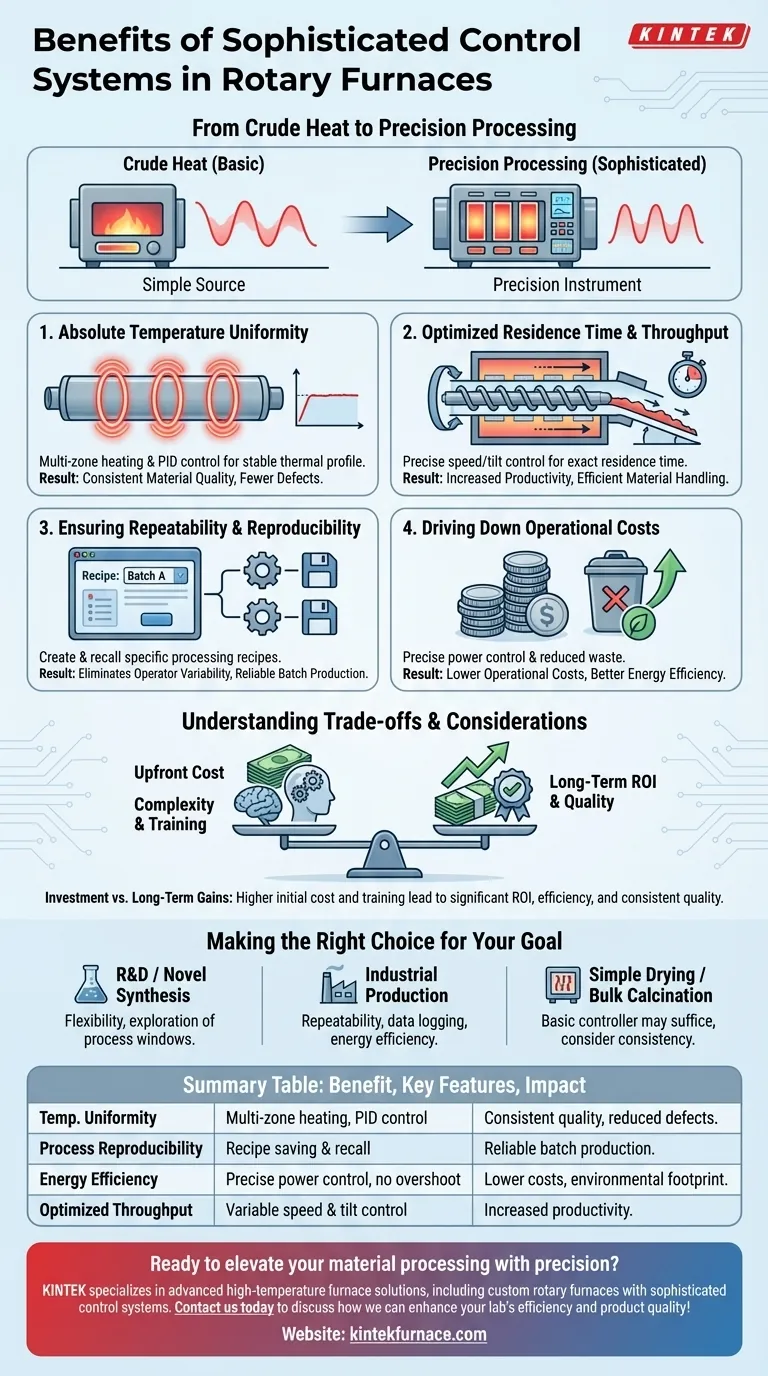

From Crude Heat to Precision Processing

A basic rotary furnace can apply heat, but it cannot guarantee the specific conditions required for advanced materials. A sophisticated control system acts as the central nervous system, coordinating multiple variables to achieve a precise and repeatable processing environment.

This transforms the furnace into a tool for targeted material transformation, not just bulk heating.

Achieving Absolute Temperature Uniformity

A key function of advanced control is managing multi-zone heating. Instead of one heater for the entire tube, the furnace is divided into several independent heating zones.

A central controller, often using a PID (Proportional-Integral-Derivative) algorithm, constantly monitors the temperature in each zone. It makes micro-adjustments to the power output, ensuring a highly uniform and stable thermal profile along the length of the tube as material travels through it.

This level of control is critical for processes where slight temperature deviations can ruin the end product.

Optimizing Residence Time and Throughput

Sophisticated systems offer precise variable speed control over the furnace's rotation. This, combined with control over the tube's tilt angle, dictates the "residence time"—how long the material spends in the hot zone.

By fine-tuning rotation speed, operators can ensure every particle receives the exact amount of thermal energy required. This optimizes throughput for continuous processing and ensures uniform treatment of the entire batch.

Ensuring Repeatability and Reproducibility

Perhaps the most significant benefit for production environments is process reproducibility. Advanced control systems allow operators to create, save, and recall specific processing "recipes."

A recipe might include a multi-step temperature profile, a specific rotation speed, and a set tilt angle. By locking in these parameters, you eliminate operator-to-operator variability and ensure that the batch produced today is identical to the one produced next month.

Driving Down Operational Costs

Precision control directly impacts the bottom line in two ways: energy efficiency and reduced material waste.

The system prevents temperature overshooting, which consumes unnecessary energy. More importantly, by ensuring a consistent and repeatable process, it drastically reduces the number of failed or out-of-spec batches, saving significant costs in wasted material, energy, and operator time.

Understanding the Trade-offs and Considerations

While the benefits are clear, adopting a sophisticated control system involves a calculated decision. Understanding the trade-offs is crucial for making an informed investment.

Initial Investment vs. Long-Term ROI

The primary barrier is the higher upfront cost. A furnace equipped with multi-zone heating, advanced sensors, and a programmable logic controller (PLC) is significantly more expensive than a basic model.

This cost must be weighed against the long-term return on investment (ROI) from increased energy efficiency, higher product yield, and improved quality, which often justifies the initial expense in production settings.

Complexity and Operator Training

These systems are more complex to operate than a simple on/off furnace. Your team will require training to effectively utilize the system's capabilities, create new processing recipes, and troubleshoot alarms.

Failing to invest in training means you may not realize the full potential of your equipment.

Maintenance and Calibration

Precision requires diligence. The temperature sensors (thermocouples) and control components need regular calibration and maintenance to ensure their accuracy.

A system that is out of calibration can be worse than a simple one, as it provides a false sense of security while producing inconsistent results.

Making the Right Choice for Your Goal

The level of control you need is directly tied to your specific application and objectives.

- If your primary focus is R&D or novel material synthesis: You require maximum flexibility with precise, multi-zone temperature profiling and variable speed control to explore new process windows.

- If your primary focus is high-volume industrial production: Your priority should be repeatability, data logging, and energy efficiency to ensure consistent product quality and maintain low operational costs.

- If your primary focus is simple drying or bulk calcination: A basic single-zone temperature controller may suffice, but evaluate if the improved consistency from a more advanced system could still reduce waste.

Ultimately, investing in an advanced control system is an investment in the quality and consistency of your final product.

Summary Table:

| Benefit | Key Features | Impact |

|---|---|---|

| Temperature Uniformity | Multi-zone heating, PID control | Ensures consistent material quality and reduces defects |

| Process Reproducibility | Recipe saving and recall | Eliminates variability for reliable batch production |

| Energy Efficiency | Precise power control, reduced overshooting | Lowers operational costs and environmental footprint |

| Optimized Throughput | Variable speed and tilt control | Increases productivity and material handling efficiency |

Ready to elevate your material processing with precision? KINTEK specializes in advanced high-temperature furnace solutions, including custom rotary furnaces with sophisticated control systems. Leveraging our exceptional R&D and in-house manufacturing, we deliver tailored options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems to meet your unique needs. Contact us today to discuss how we can enhance your lab's efficiency and product quality!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials