At its core, Insulated Gate Bipolar Transistor (IGBT) technology gives you unparalleled command over the power supplied to an induction furnace. This direct control over power translates into exceptionally precise and uniform temperature control, which is critical for achieving high-quality melts and meeting stringent industry standards.

The true advantage of IGBTs is not just better temperature control, but the combination of precision, energy efficiency, and operational speed it enables. It represents a fundamental shift from older, less efficient heating methods toward a more reliable and cost-effective process.

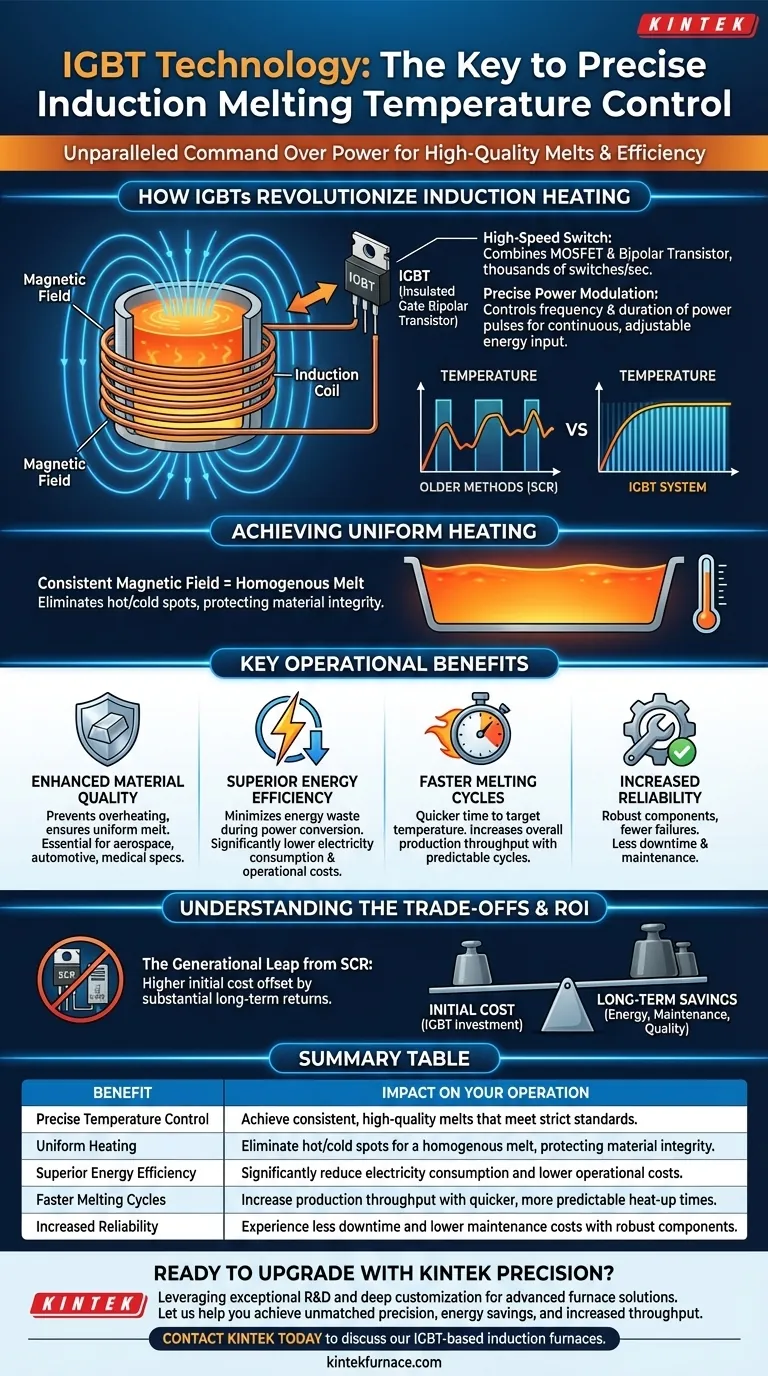

How IGBTs Revolutionize Induction Heating

To understand the benefits, we must first look at the mechanism. An induction furnace works by using a powerful, alternating magnetic field to induce electrical currents within the metal, which in turn generates heat. The IGBT is the component that controls the electricity flowing to the induction coil.

The IGBT as a High-Speed Switch

An IGBT is a sophisticated semiconductor device that acts as an extremely fast and efficient electronic switch. It combines the low power requirements of a MOSFET gate with the high-current handling capability of a bipolar transistor.

This design allows it to turn large amounts of electrical current on and off thousands of times per second with minimal energy loss.

Translating Power Switching to Temperature Control

The temperature of the melt is a direct result of the energy delivered by the induction coil. By precisely modulating the frequency and duration of the power pulses it sends to the coil, the IGBT system gives you exact control over the energy input.

This is fundamentally more precise than older methods. Instead of crude on/off cycles, you get a continuous and highly adjustable power stream, allowing the system to hit and hold a target temperature with remarkable accuracy.

Achieving Uniform Heating

This level of control ensures the magnetic field is consistent, leading to uniform heating throughout the entire volume of material. This eliminates hot spots that can degrade material quality and cold spots that slow down the melting process, ensuring the final product is homogenous.

Key Operational Benefits of IGBT Technology

The precision offered by IGBTs creates a cascade of benefits that impact everything from product quality to your bottom line.

Enhanced Material Quality and Integrity

By preventing overheating and ensuring a uniform melt, IGBT-based systems protect the integrity of the metals being processed. This is essential for industries like aerospace, automotive, and medical manufacturing where material specifications are non-negotiable.

Superior Energy Efficiency

IGBTs are vastly more efficient at switching power than older technologies like Silicon Controlled Rectifiers (SCR). They minimize energy wastage during the power conversion process, which directly translates to lower electricity consumption and reduced operational costs.

Faster and More Consistent Melting

Because power is delivered so efficiently and precisely, the target temperature is reached more quickly. This results in faster melting times and more predictable, repeatable cycles, which increases overall production throughput.

Increased Reliability and Uptime

Modern IGBT components are robust and reliable. Furnaces built with this technology experience fewer component failures, leading to significantly less maintenance, reduced downtime, and more consistent production schedules.

Understanding the Trade-offs

While IGBT technology is superior, it's important to understand the full context.

The Generational Leap from SCR Systems

Older induction systems often use SCRs for power control. While functional, SCRs are less efficient, offer slower and less precise control, and can introduce more harmonic pollution into the electrical grid. The move to IGBTs is a clear technological upgrade for any modern operation.

Initial Cost vs. Long-Term ROI

An IGBT-powered induction furnace may represent a higher initial capital investment compared to a system with older technology. However, this cost is typically offset quickly by substantial energy savings, lower maintenance bills, and higher product quality leading to less waste.

The Importance of System Integration

The full benefit of an IGBT is realized when it is part of a well-designed system with a responsive feedback loop. High-quality temperature sensors and control logic are necessary to leverage the IGBT's speed and precision effectively.

Making the Right Choice for Your Operation

Choosing to invest in IGBT technology depends on your specific operational priorities.

- If your primary focus is meeting stringent quality standards: The precise and uniform heating of IGBT systems is the most reliable way to produce consistent, high-grade melts.

- If your primary focus is reducing operational costs: The significant energy efficiency and lower maintenance needs of IGBT technology will deliver a strong and measurable return on investment.

- If your primary focus is maximizing production throughput: The faster and more predictable melting cycles enabled by IGBTs will directly increase your plant's output capacity.

Ultimately, adopting IGBT technology is a strategic investment in the precision, efficiency, and reliability of your entire melting process.

Summary Table:

| Benefit | Impact on Your Operation |

|---|---|

| Precise Temperature Control | Achieve consistent, high-quality melts that meet strict industry standards. |

| Uniform Heating | Eliminate hot/cold spots for a homogenous melt, protecting material integrity. |

| Superior Energy Efficiency | Significantly reduce electricity consumption and lower operational costs. |

| Faster Melting Cycles | Increase production throughput with quicker, more predictable heat-up times. |

| Increased Reliability | Experience less downtime and lower maintenance costs with robust components. |

Ready to Upgrade Your Melting Process with IGBT Precision?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and foundries with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental and production requirements.

Let us help you achieve:

- Unmatched melting precision for superior product quality.

- Significant reductions in energy consumption and operational costs.

- Increased throughput with faster, more reliable melting cycles.

Contact KINTEL today to discuss how our IGBT-based induction furnaces can transform your operation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys