At their core, dental ceramic furnaces are specialized ovens used to process and finalize ceramic-based dental restorations. Their applications are central to modern restorative dentistry, including the fabrication of crowns, bridges, veneers, inlays, onlays, and implant prosthetics. These furnaces use precise temperature control to transform raw ceramic materials into strong, durable, and aesthetically pleasing final products that mimic natural teeth.

The fundamental problem is that dental ceramics in their initial state are too weak to withstand the forces of the mouth. The dental furnace solves this by using controlled heat—and sometimes pressure—to sinter the material, creating the structural integrity, biocompatibility, and lifelike appearance essential for any successful dental restoration.

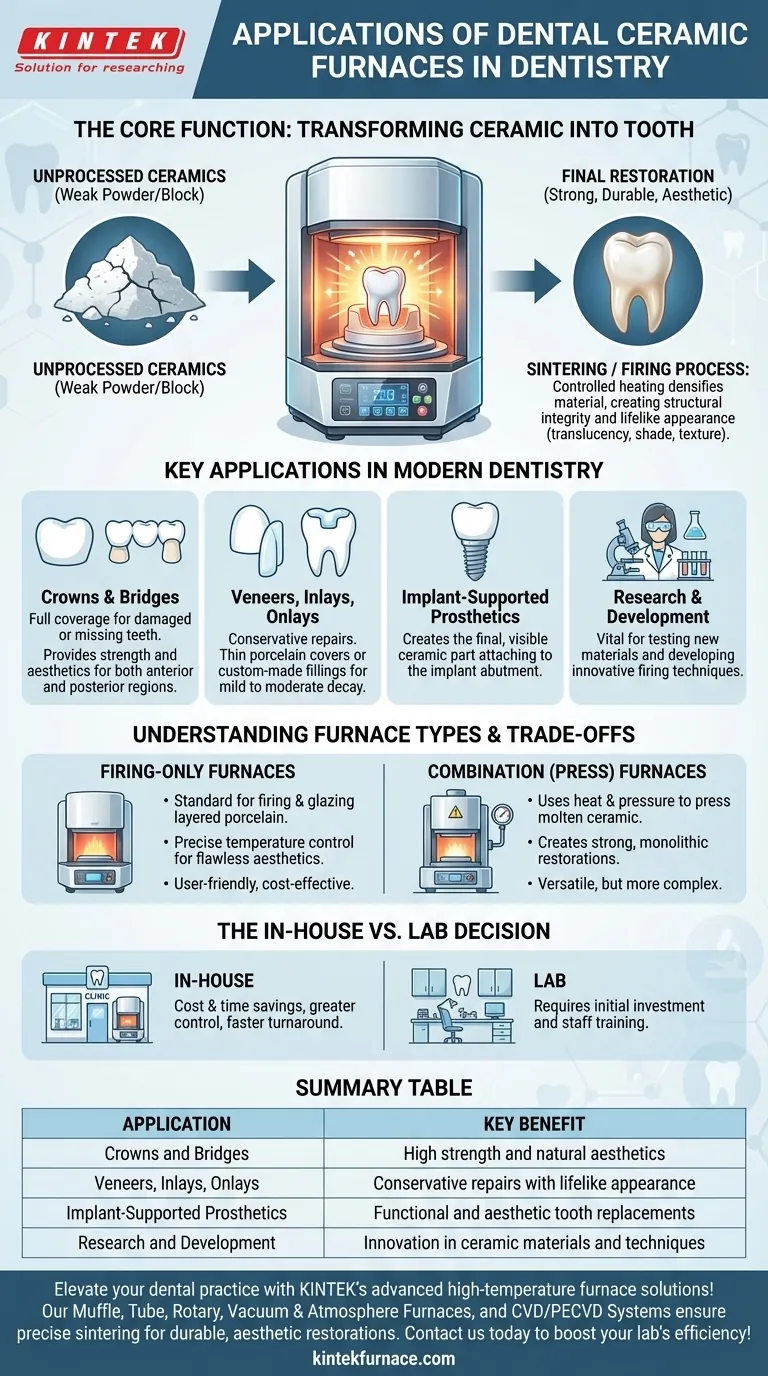

The Core Function: Transforming Ceramic into Tooth

A dental furnace is the critical link between a digitally designed or manually shaped restoration and the final product placed in a patient's mouth. Its role is to execute a precise thermal process that permanently changes the ceramic's properties.

The Problem of Unprocessed Ceramics

Unprocessed dental ceramic materials, whether in powder or block form, lack the necessary hardness and fracture resistance. They cannot endure the functional forces generated during chewing and would fail almost immediately in the oral environment.

The Role of Sintering and Firing

The furnace subjects the ceramic to a meticulously controlled heating cycle, a process known as sintering or firing. This process densifies the material and fuses the ceramic particles together, creating a monolithic structure with immense strength and durability.

Achieving Lifelike Aesthetics

This controlled heating is also what develops the final aesthetic properties. The firing program dictates the material's translucency, shade, and surface texture, allowing technicians to create restorations that are virtually indistinguishable from natural teeth.

Key Applications in Modern Dentistry

The versatility of dental ceramic furnaces makes them indispensable for a wide range of restorative and cosmetic procedures.

Crowns and Bridges

The most common application is the fabrication of all-ceramic crowns (to cover a single tooth) and bridges (to replace one or more missing teeth). The furnace ensures these restorations have the strength to function as posterior teeth and the beauty to serve as anterior teeth.

Veneers, Inlays, and Onlays

For more conservative treatments, furnaces are used to create thin porcelain veneers that cover the front surface of teeth. They also produce inlays and onlays, which are custom-made fillings used to repair teeth with mild to moderate decay.

Implant-Supported Prosthetics

In implant dentistry, the furnace is used to create the final ceramic crown or bridge that attaches to the dental implant abutment. This provides the visible, functional, and aesthetic part of the tooth replacement.

Research and Development

In dental laboratories and research institutions, these furnaces are vital for testing new ceramic materials and developing innovative firing techniques to improve the quality and longevity of dental restorations.

Understanding the Trade-offs and Furnace Types

Not all ceramic furnaces are the same. The choice of furnace depends on the types of materials and restorations a dental practice or laboratory intends to produce.

Firing-Only Furnaces

These are the standard furnaces designed primarily for firing and glazing layered porcelain. They excel at precise temperature control, making them ideal for achieving flawless aesthetics in crowns and veneers. They are often more compact, user-friendly, and cost-effective for practices focused on traditional porcelain work.

Combination (Press) Furnaces

These more versatile units can perform standard firing cycles but also use pressure in combination with heat. This allows them to press molten ceramic ingots into a mold, a process used for creating extremely strong and well-fitting monolithic restorations. While more versatile, they can be more complex and represent a larger initial investment.

The In-House vs. Lab Decision

A key strategic decision for a dental practice is whether to purchase a furnace or outsource to a lab. An in-house furnace offers significant cost and time savings, greater control over customization and quality, and faster turnaround times for patients. However, it requires an initial investment and staff training.

Making the Right Choice for Your Practice

Choosing the right equipment depends entirely on your clinical goals, patient needs, and business model.

- If your primary focus is aesthetic excellence with layered porcelain: A dedicated firing-only furnace offers the precision and cost-effectiveness you need.

- If your primary focus is versatility and high-strength restorations: A combination press furnace will allow you to work with a broader range of advanced ceramic materials.

- If your primary focus is workflow efficiency and quality control: Bringing any type of furnace in-house can dramatically reduce restoration turnaround times and improve patient satisfaction.

Ultimately, the dental ceramic furnace is a cornerstone technology that empowers dental professionals to deliver durable, biocompatible, and highly aesthetic restorative care.

Summary Table:

| Application | Key Benefit |

|---|---|

| Crowns and Bridges | High strength and natural aesthetics for tooth restoration |

| Veneers, Inlays, Onlays | Conservative repairs with lifelike appearance |

| Implant-Supported Prosthetics | Functional and aesthetic tooth replacements |

| Research and Development | Innovation in ceramic materials and techniques |

Elevate your dental practice with KINTEK's advanced high-temperature furnace solutions! Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization, ensure precise sintering for durable, aesthetic restorations like crowns and veneers. Contact us today to discuss how we can meet your unique needs and boost your lab's efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations