At its core, a dental lab furnace is a high-precision oven used for the thermal processing of dental materials. Its primary applications are melting metal alloys for casting the framework of restorations and firing ceramic materials like porcelain to give them their final strength, shape, and color. These processes are fundamental to creating everything from single crowns to complex bridgework and implant-supported prosthetics.

A dental lab furnace is not merely a heating device; it is a critical instrument of transformation. Its value lies in its ability to precisely control extreme heat, turning raw powders and metals into the strong, perfectly-fitting, and aesthetic restorations that modern dentistry demands.

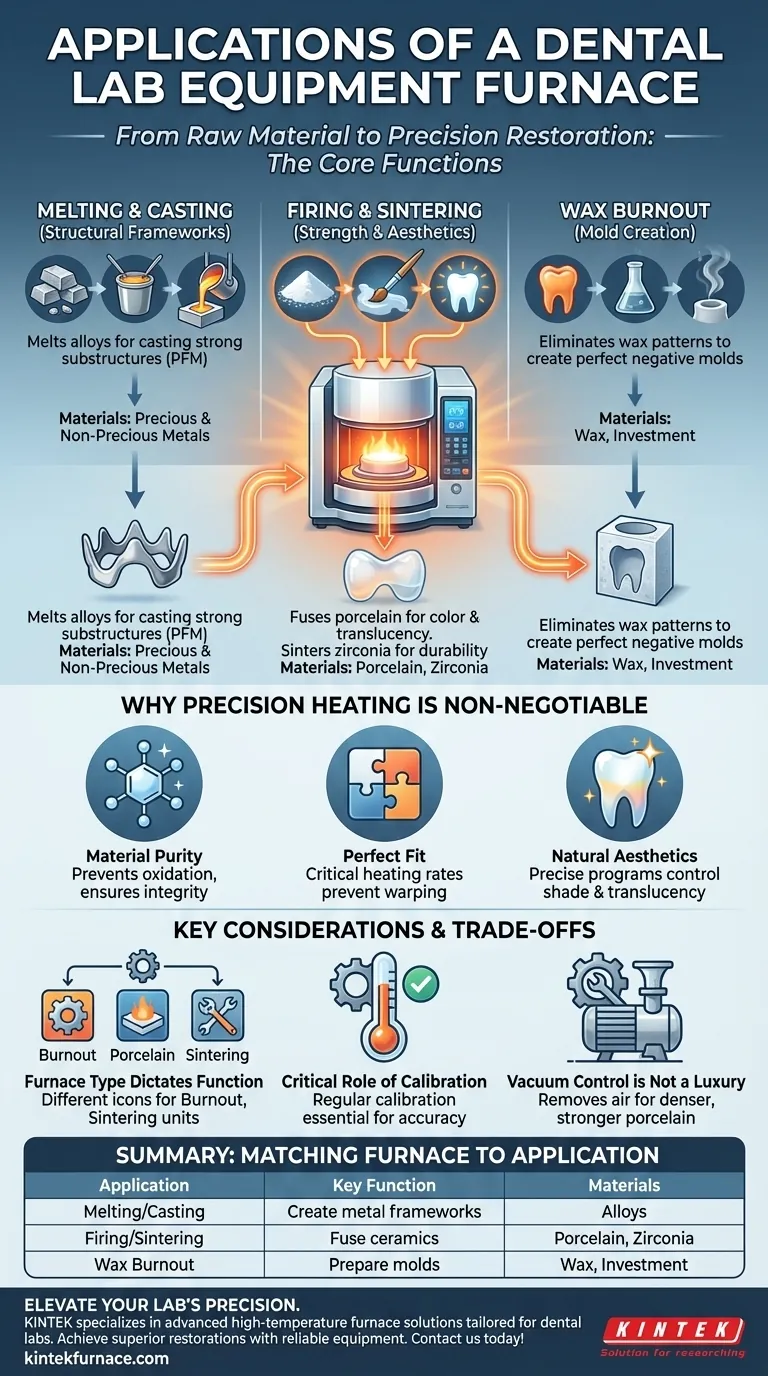

The Core Functions: From Raw Material to Restoration

A furnace is central to several distinct stages of dental fabrication. Each process requires a specific application of heat to achieve the desired material properties.

Melting and Casting for Structural Frameworks

The foundation of many restorations, like a porcelain-fused-to-metal (PFM) crown, is a metal substructure. The furnace melts alloys—ranging from non-precious to precious metals—to a liquid state. This molten metal is then cast into a mold to create the strong, underlying framework that will support the aesthetic porcelain layers.

Firing and Sintering for Strength and Aesthetics

This process applies to ceramic materials like porcelain and zirconia.

- Firing porcelain involves heating it through carefully programmed cycles. This doesn't melt the material but causes the particles to fuse together, creating a dense, hard, and vitreous (glass-like) surface with the desired shade and translucency.

- Sintering is a similar process used for materials like zirconia. The furnace brings the "green state" zirconia to extremely high temperatures (often over 1500°C), causing it to shrink and densify into one of the strongest and most durable materials in dentistry.

Wax Burnout for Mold Creation

Before metal can be cast, a highly detailed wax model of the restoration is created. This wax pattern is encased in a heat-resistant material called investment. The furnace is then used to completely burn away the wax, leaving a perfect negative-space mold inside the investment, ready to receive the molten alloy.

Why Precision Heating is Non-Negotiable

The success or failure of a dental restoration often comes down to fractions of a percent in dimension and specific material properties, all of which are dictated by heat.

Ensuring Material Purity and Integrity

Incorrect temperatures can ruin expensive materials. Many advanced furnaces operate under a vacuum or in low-oxygen environments. This prevents oxidation of the metal alloys during melting, which ensures a stronger, cleaner, and more biocompatible final casting.

Achieving a Perfect Anatomical Fit

The heating and cooling rates during a firing or casting cycle are critical. If done improperly, the material can warp, shrink unevenly, or develop internal stress. This results in a restoration that simply will not fit the patient's tooth, leading to costly remakes and wasted chair time.

Creating Natural Aesthetics

For ceramics, the firing program is an art form. The precise temperatures, hold times, and rate of heating directly control the final shade, translucency, and surface texture. This is how a skilled technician creates a crown that is indistinguishable from a natural tooth.

Understanding the Trade-offs and Key Considerations

While essential, not all furnaces are created equal, and their application requires expertise.

Furnace Type Dictates Function

A furnace designed for wax burnout and casting alloys is mechanically and programmatically different from one designed for firing aesthetic porcelain. Sintering furnaces are another category entirely, built to handle the extreme temperatures required for zirconia. While some "combi" furnaces exist, specialized units often deliver superior results for their specific task.

The Critical Role of Calibration

A furnace is only as reliable as its temperature readings. Over time, the thermocouple that measures temperature can degrade and provide inaccurate readings. Regular calibration is not optional; it is essential maintenance to prevent catastrophic failures of entire batches of work.

Vacuum Control is Not a Luxury

For high-end porcelain work, a vacuum pump integrated with the furnace is crucial. Pulling a vacuum during the firing cycle removes air trapped between porcelain particles. This eliminates porosity (bubbles) and results in a much stronger, denser, and more translucent final restoration.

Matching the Furnace to Your Lab's Needs

Choosing the right furnace depends entirely on the type of restorations you produce.

- If your primary focus is crown and bridge metalwork: A reliable burnout and casting furnace with a large muffle (heating chamber) and accurate temperature control is your essential workhorse.

- If your primary focus is aesthetic ceramics (veneers, layered crowns): You need a dedicated porcelain furnace with highly programmable cycles, precise temperature ramping, and an excellent vacuum system.

- If your primary focus is modern zirconia restorations: A high-temperature sintering furnace capable of reaching and holding temperatures above 1500°C is non-negotiable.

- If you run a versatile, full-service lab: You will likely need to invest in separate, specialized units for burnout/casting, porcelain firing, and sintering to optimize workflow and quality.

Ultimately, selecting the right dental furnace is an investment in the precision required to deliver consistent, high-quality patient outcomes.

Summary Table:

| Application | Key Function | Materials Used |

|---|---|---|

| Melting and Casting | Creates metal frameworks for restorations | Alloys (e.g., precious, non-precious metals) |

| Firing and Sintering | Fuses ceramics for strength and color | Porcelain, zirconia |

| Wax Burnout | Prepares molds by removing wax patterns | Wax, investment materials |

Ready to elevate your dental lab's precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique needs for melting, casting, firing, and sintering. Achieve superior restorations with reliable, calibrated equipment—contact us today to discuss how we can support your workflow and deliver consistent, high-quality results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab