In short, using thermal insulation material in a rotary cement kiln is a standard practice because it directly reduces heat lost from the kiln shell. This fundamental improvement lowers overall energy consumption, decreases fuel costs, and enhances the stability of the entire clinker production process.

The core principle is simple: every unit of heat retained within the kiln is a unit of fuel you don't have to burn. Proper insulation transforms the kiln from a high-loss system into a more efficient, controlled thermodynamic environment, yielding benefits far beyond just energy savings.

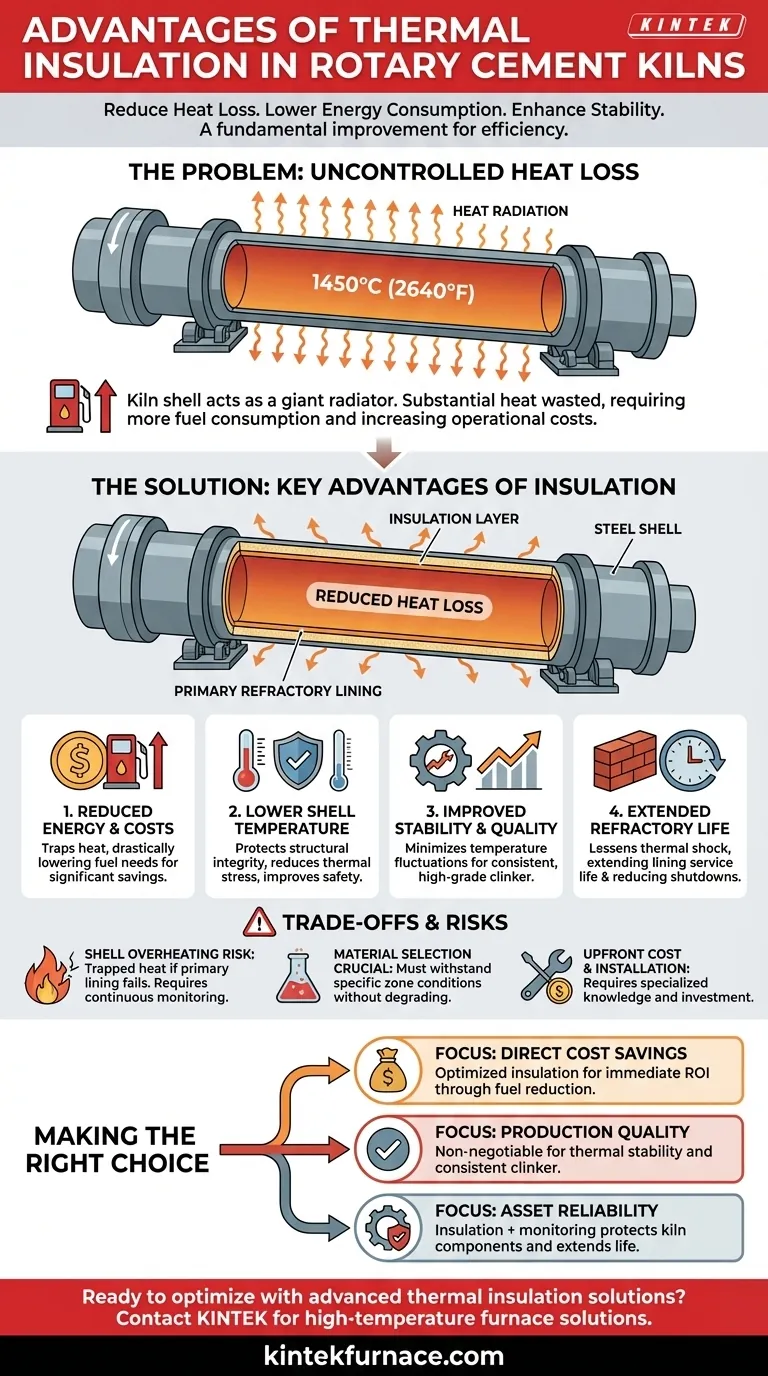

The Problem: Uncontrolled Heat Loss

A rotary cement kiln is essentially a massive, rotating furnace designed to heat raw materials to approximately 1450°C (2640°F). At these extreme temperatures, uncontrolled heat loss is a significant operational and financial drain.

The Scale of Thermal Radiation

The large surface area of the kiln's steel shell acts like a giant radiator. Without insulation, a substantial portion of the heat generated by burning fuel radiates away into the surrounding atmosphere, completely wasted.

The Impact on Fuel Consumption

To compensate for this constant heat loss, the kiln's burner must consume more fuel—such as coal, petcoke, or alternative fuels—to maintain the required internal temperature for the clinkerization process. This directly increases operational costs.

Key Advantages of Kiln Insulation

Implementing a layer of insulation between the kiln's steel shell and its primary refractory lining provides several critical advantages that address the problem of heat loss.

1. Reduced Energy Consumption & Costs

This is the most direct and easily quantifiable benefit. By trapping heat inside the kiln, insulation drastically reduces the amount of fuel needed to maintain the target process temperature. This translates into significant and immediate cost savings.

2. Lower Kiln Shell Temperature

A well-insulated kiln will have a much lower external shell temperature. This is a crucial secondary benefit that protects the kiln's structural integrity by reducing thermal stress on the steel shell, support rollers, and drive mechanisms. It also improves safety for personnel working near the kiln.

3. Improved Process Stability and Clinker Quality

Insulation helps create a more stable and uniform temperature profile along the length of the kiln. This stability is vital for process control, as it minimizes fluctuations that can negatively impact the chemical reactions forming the cement clinker. The result is a more consistent, higher-quality final product.

4. Extended Refractory Lining Life

The insulating layer reduces the thermal gradient across the main, dense refractory brick. This lessens the thermal shock and stress the brick experiences during heat-up and operation, which can extend the service life of the expensive refractory lining and reduce the frequency of costly shutdowns for maintenance.

Understanding the Trade-offs and Risks

While highly beneficial, insulation is not without its challenges. A successful strategy requires careful engineering and material selection.

The Risk of Shell Overheating

The primary risk is trapping too much heat. If the primary refractory lining fails or thins unexpectedly, the insulation can prevent that heat from escaping, concentrating it against the steel shell. This can cause the shell to overheat, leading to red spots, deformation, and potential catastrophic failure. Continuous shell temperature monitoring is critical.

Material Selection is Crucial

Different zones of the kiln have unique thermal and chemical conditions. The insulation material must be chosen to withstand the specific temperature, pressure, and chemical environment of its location without degrading, compacting, or reacting with the primary refractory.

Upfront Cost and Installation

Adding an insulation layer represents an additional material and labor cost during a kiln reline. It requires specialized knowledge to install correctly, ensuring tight joints and proper layering to achieve the desired thermal performance without creating new risks.

Making the Right Choice for Your Goal

The decision to use insulation is clear, but the strategy depends on your specific operational priorities.

- If your primary focus is direct cost savings: An optimized insulation package offers the most significant and immediate return on investment through reduced fuel consumption.

- If your primary focus is production quality: Insulation is non-negotiable for achieving the thermal stability required for consistent, high-grade clinker.

- If your primary focus is long-term asset reliability: A well-designed insulation system, paired with rigorous shell temperature monitoring, protects the kiln's mechanical components and can extend refractory life, reducing overall maintenance costs.

Ultimately, implementing a proper thermal insulation strategy is a fundamental step in modernizing a cement plant for efficiency, stability, and profitability.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Reduced Energy Consumption | Lowers fuel usage and operational costs |

| Lower Kiln Shell Temperature | Protects structural integrity and improves safety |

| Improved Process Stability | Ensures consistent, high-quality clinker production |

| Extended Refractory Lining Life | Reduces maintenance frequency and costs |

Ready to optimize your cement kiln operations with advanced thermal insulation solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored for cement plants. Our product line, including Rotary Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique thermal management needs. Contact us today to enhance efficiency, reduce costs, and improve product quality!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What is the retention time of a rotary kiln? Optimize Your Process Efficiency

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing