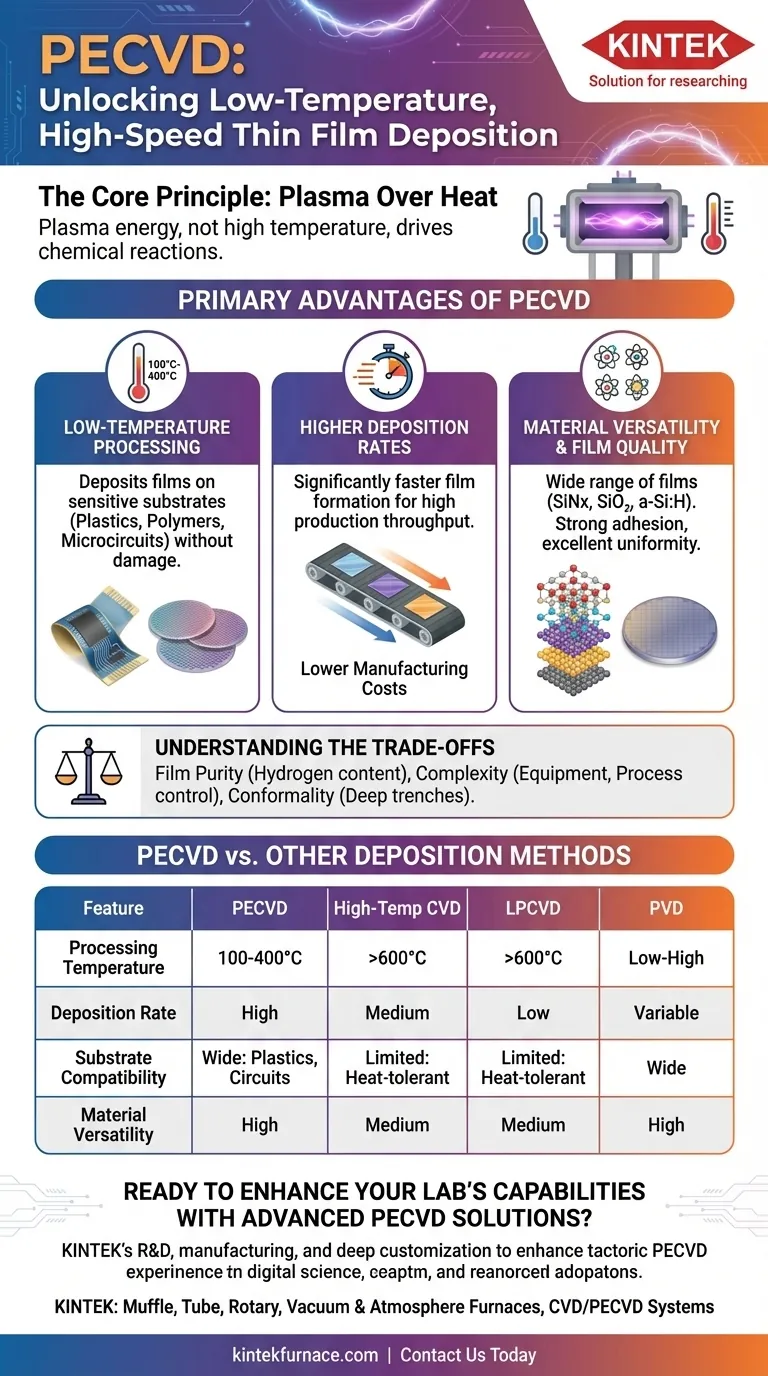

The primary advantages of PECVD are its ability to deposit high-quality thin films at significantly lower temperatures, at faster rates, and with a wider range of materials than conventional methods. This unique combination makes it indispensable for manufacturing modern electronics, medical devices, and advanced materials where temperature-sensitive components or high production throughput are critical concerns.

The core principle behind PECVD is using an energy-rich plasma, not just high heat, to drive the chemical reactions needed for film deposition. This decoupling from thermal energy is the key that unlocks its main advantages: compatibility with sensitive substrates and superior manufacturing efficiency.

The Core Principle: How Plasma Changes the Game

Traditional Chemical Vapor Deposition (CVD) relies on high temperatures (often >600°C) to provide enough energy to break down precursor gases and deposit a film. PECVD circumvents this by creating a plasma, an ionized gas containing highly reactive free radicals, ions, and electrons.

Low-Temperature Processing

This plasma provides the necessary energy for chemical reactions to occur at much lower substrate temperatures, typically between 100°C and 400°C.

This is not just a minor improvement; it is a fundamental shift that enables entirely new applications. It allows for deposition on materials that would melt, warp, or be damaged by the high heat of thermal CVD.

Expanding Substrate Compatibility

The low-temperature nature of PECVD makes it compatible with a vast array of temperature-sensitive substrates. This includes plastics, polymers, and fully processed semiconductor wafers containing delicate microelectronic circuits whose dopant profiles could be altered by excessive heat.

Key Performance Advantages

The use of a plasma-driven process translates directly into tangible benefits in film quality, speed, and versatility.

Higher Deposition Rates

The chemical species within the plasma are extremely reactive. This leads to significantly faster film formation compared to many thermal CVD and Physical Vapor Deposition (PVD) processes.

What might take hours with other methods can often be accomplished in minutes with PECVD. This drastically increases production throughput and lowers manufacturing costs, especially in high-volume settings like semiconductor fabrication.

Excellent Film Properties and Uniformity

Despite the lower temperature, PECVD can produce films with excellent characteristics. These include strong substrate adhesion, good electrical properties, and high uniformity across large-area substrates like silicon wafers.

The process offers precise control over film properties, allowing engineers to fine-tune the final product for specific performance requirements.

Unmatched Material Versatility

PECVD is not limited to a narrow set of materials. The high-energy plasma environment facilitates the deposition of a wide variety of films, including:

- Silicon Nitride (SiNx)

- Silicon Dioxide (SiO₂)

- Amorphous Silicon (a-Si:H)

- Polymers and other organic compounds

This flexibility makes PECVD a powerful tool for designing advanced material stacks and novel devices.

Understanding the Trade-offs

No technology is a universal solution. While powerful, PECVD has considerations that must be weighed against its benefits.

Film Purity and Hydrogen Content

Because PECVD processes often use hydrogen-containing precursor gases (like silane, SiH₄), some hydrogen can be incorporated into the deposited film. This can impact the film's density and electrical characteristics. For applications demanding the absolute highest purity and density, high-temperature thermal CVD may still be superior.

Process and Equipment Complexity

A PECVD system is more complex than a simple thermal CVD furnace. It involves a vacuum chamber, gas delivery systems, and RF or microwave power sources to generate and sustain the plasma. Controlling the plasma adds process variables that require careful optimization to achieve consistent results.

Conformal Coverage

While PECVD generally offers good coverage over surface features, it can be less "conformal" than some low-pressure CVD (LPCVD) techniques. This means it may struggle to perfectly coat the inside of very deep, narrow trenches, a key consideration for increasingly small microelectronic devices.

Making the Right Choice for Your Application

Selecting a deposition method requires aligning the technique's strengths with your project's primary goal. PECVD is a powerful and versatile option, but its suitability depends on your specific constraints.

- If your primary focus is depositing on temperature-sensitive substrates (plastics, polymers, or complex circuits): PECVD is almost always the superior choice due to its low-temperature operation.

- If your primary focus is high-throughput manufacturing and cost efficiency: PECVD's high deposition rates offer a clear advantage for mass production.

- If your primary focus is achieving the highest possible film purity and density, and your substrate can tolerate heat: High-temperature thermal CVD may provide better results for certain demanding applications.

- If your primary focus is creating novel films from a wide variety of precursors: PECVD's material versatility gives you a much larger toolbox to work with.

By understanding that PECVD trades thermal energy for plasma energy, you can confidently determine when its unique advantages are the right fit for your goals.

Summary Table:

| Advantage | Description |

|---|---|

| Low-Temperature Processing | Deposits films at 100-400°C, ideal for sensitive substrates like plastics and semiconductors. |

| High Deposition Rates | Faster film formation increases throughput and reduces manufacturing costs. |

| Material Versatility | Supports a wide range of films including silicon nitride, silicon dioxide, and amorphous silicon. |

| Excellent Film Properties | Provides strong adhesion, good electrical characteristics, and high uniformity. |

Ready to enhance your lab's capabilities with advanced PECVD solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're working on electronics, medical devices, or advanced materials, our PECVD systems can help you achieve low-temperature, high-speed deposition with superior film quality.

Contact us today to discuss how we can tailor a solution for your specific requirements and drive your innovations forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication