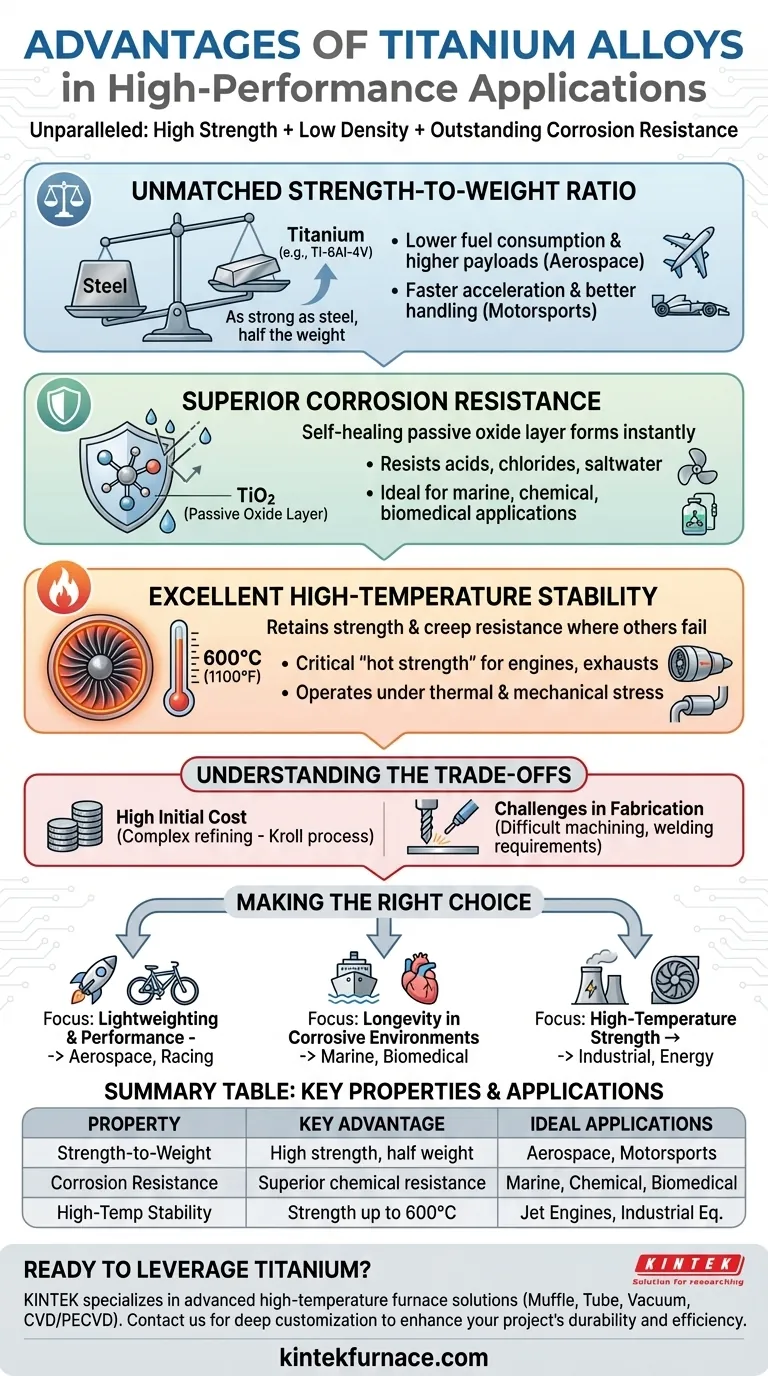

Fundamentally, titanium alloys offer an unparalleled combination of high strength, low density, and outstanding corrosion resistance. This unique profile makes them the material of choice for demanding applications where performance and reliability are critical, from aerospace components to chemical processing equipment. While more expensive than steel or aluminum, its properties often enable designs and levels of durability that other materials simply cannot achieve.

The decision to use titanium is rarely about finding the cheapest option. It is about investing in superior performance, reducing long-term lifecycle costs, and enabling designs that would otherwise be impossible due to weight or environmental constraints.

The Core Properties Defining Titanium's Performance

To understand if titanium is right for your project, you must look beyond the price tag and evaluate its three defining characteristics. These properties work in concert to create a uniquely capable engineering material.

The Unmatched Strength-to-Weight Ratio

This is arguably titanium's most famous attribute. A component made from a common titanium alloy like Ti-6Al-4V can be as strong as many alloy steels but at nearly half the weight.

This has profound implications for any application where mass is a penalty. In aerospace, it means lower fuel consumption and higher payloads. In motorsports, it translates to faster acceleration and better handling.

Superior Corrosion Resistance

Titanium's resistance to corrosion is exceptional, often surpassing that of stainless steel. This is not an inherent property of the metal itself but is due to the formation of a highly stable, tenacious, and self-healing passive oxide layer (TiO₂) on its surface.

This inert film instantly reforms if scratched, protecting the underlying metal from attack by a wide range of acids, chlorides, and saltwater. This makes it an ideal material for marine hardware, chemical reactors, and biomedical implants.

Excellent High-Temperature Stability

While aluminum alloys begin to lose their strength significantly above 200°C, many titanium alloys retain excellent strength and creep resistance at temperatures up to 600°C (1100°F).

This "hot strength" is critical for components in the hot sections of jet engines, automotive exhaust systems, and industrial processing equipment that operate under both thermal and mechanical stress.

Understanding the Trade-offs

No material is perfect, and titanium's elite performance comes with significant challenges that must be factored into any design decision. Being aware of these trade-offs is key to a successful project.

The High Initial Cost

There is no avoiding the fact that titanium alloys are expensive. The raw material cost is significantly higher than that of aluminum or steel, driven by the complex and energy-intensive Kroll process used to refine it from ore.

Challenges in Fabrication

The cost of a finished part is not just in the material. Titanium is notoriously difficult and expensive to machine. Its properties can lead to rapid tool wear and slow machining speeds.

Furthermore, welding titanium requires meticulous preparation and the use of inert gas shielding to prevent contamination from atmospheric oxygen and nitrogen, which can make the weld brittle and prone to failure.

Making the Right Choice for Your Application

The decision to specify a titanium alloy should be a deliberate one, driven by a clear engineering need that other materials cannot meet effectively or safely.

- If your primary focus is lightweighting and absolute performance: The superior strength-to-weight ratio is often a non-negotiable advantage that justifies the cost in aerospace, racing, and high-end sporting goods.

- If your primary focus is longevity in corrosive environments: Titanium's inertness provides unmatched reliability and can lead to lower lifetime maintenance and replacement costs in marine, chemical, and desalination applications.

- If your primary focus is high-temperature strength: Titanium alloys provide a critical performance window where lighter metals like aluminum cannot operate and where the weight penalty of nickel superalloys is unacceptable.

Ultimately, selecting titanium is an investment in maximizing performance, ensuring long-term durability, and unlocking new design possibilities.

Summary Table:

| Property | Key Advantage | Ideal Applications |

|---|---|---|

| Strength-to-Weight Ratio | High strength at half the weight of steel | Aerospace, motorsports, sporting goods |

| Corrosion Resistance | Superior resistance to acids, chlorides, and saltwater | Marine hardware, chemical reactors, biomedical implants |

| High-Temperature Stability | Maintains strength up to 600°C | Jet engines, automotive exhausts, industrial equipment |

Ready to leverage titanium alloys for your high-performance needs? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements. Contact us today to discuss how we can enhance your project's durability and efficiency!

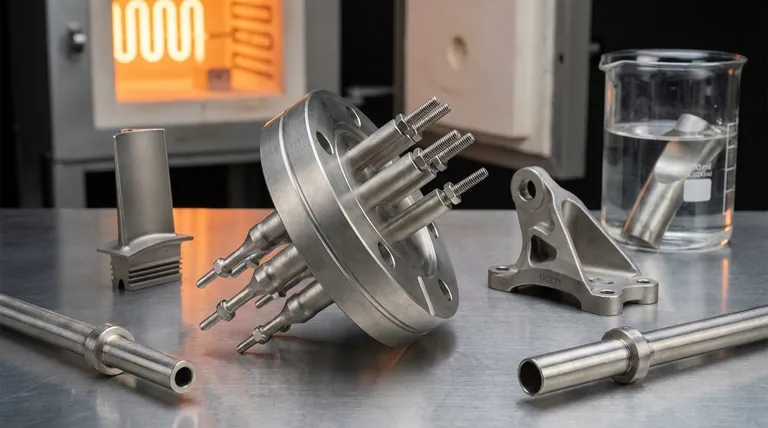

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?