In vacuum furnace operations, the lightweight and high-strength nature of graphite directly translates to lower operational costs, easier installation, and improved safety. These physical properties allow for simpler handling of large furnace components, reducing labor requirements and minimizing wear on the furnace's internal support structures during maintenance and part replacement.

While the practical benefits of its strength-to-weight ratio are significant, graphite's true indispensability in vacuum furnaces stems from its unique and unparalleled combination of extreme thermal stability, chemical inertness, and electrical conductivity at temperatures where most metals would have failed.

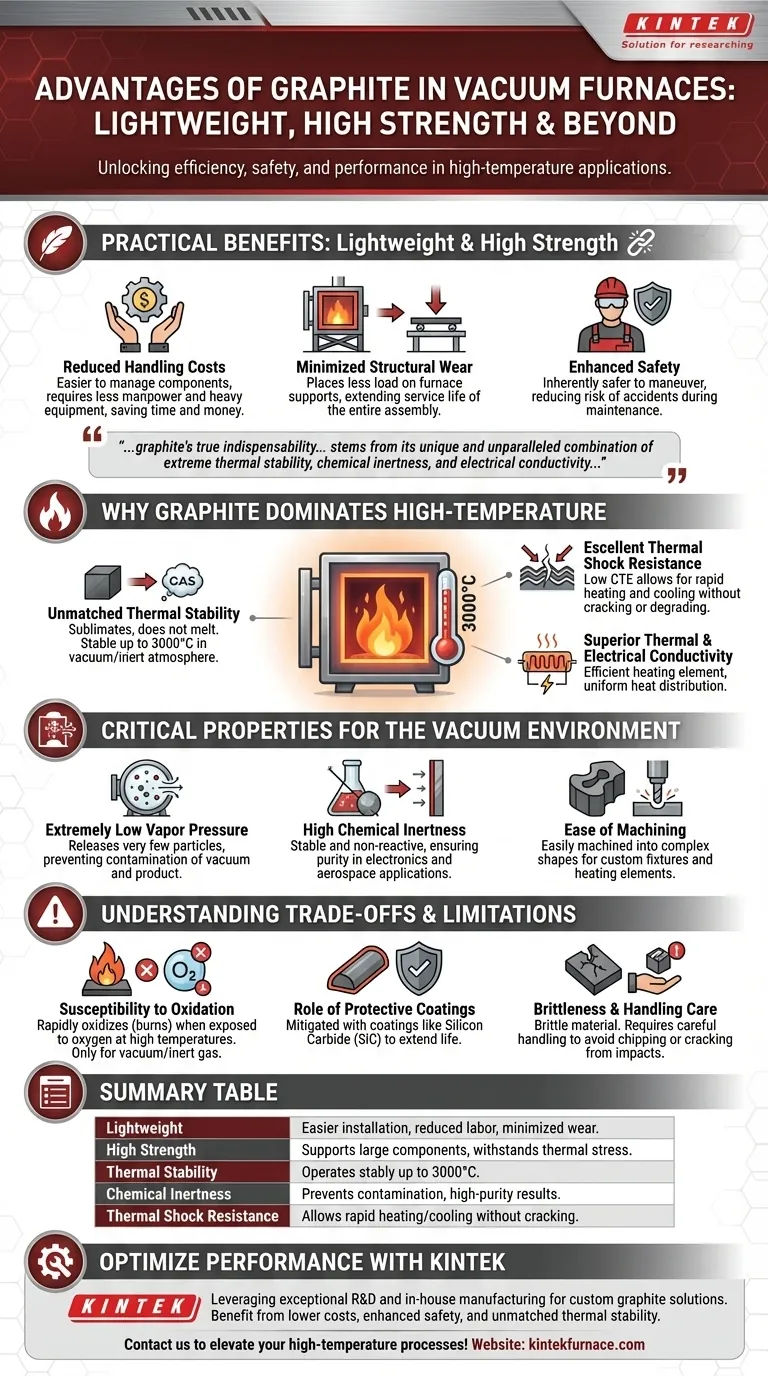

The Practical Benefits: Lightweight and High Strength

The most immediately apparent advantages of graphite relate to its physical handling and its impact on the furnace structure itself. These benefits are foundational to its widespread use.

Reduced Handling Costs and Effort

Lighter components are fundamentally easier to manage. Using graphite for large fixtures, heating elements, or insulation means installation and removal can often be done with less manpower and without heavy-duty lifting equipment, saving both time and money.

Minimized Structural Wear

Graphite parts place significantly less static and dynamic load on the furnace's support systems. This reduces long-term wear and tear on rails, hangers, and other structural elements, extending the service life of the entire furnace assembly.

Enhanced Safety

Handling massive, heavy components made from refractory metals poses significant safety risks to technicians. The lightweight nature of graphite parts makes them inherently safer to maneuver, reducing the risk of accidents and injuries during maintenance cycles.

Why Graphite Dominates High-Temperature Applications

Beyond its physical handling advantages, graphite possesses a suite of thermal and electrical properties that make it the premier material for high-performance vacuum and inert-gas furnaces.

Unmatched Thermal Stability

Graphite does not melt at atmospheric pressure; instead, it sublimates (turns directly from a solid to a gas) at extremely high temperatures. It can operate stably in a vacuum or inert atmosphere at temperatures up to 3000°C, far exceeding the limits of most other materials.

Excellent Thermal Shock Resistance

Furnaces undergo rapid heating and cooling cycles. Graphite's very low coefficient of thermal expansion (CTE) and high thermal conductivity allow it to withstand these drastic temperature changes without cracking or degrading, ensuring component longevity and process repeatability.

Superior Thermal and Electrical Conductivity

Graphite is unique in that it serves a dual purpose. Its low resistivity allows it to function as a highly efficient heating element, generating radiant heat when an electrical current is applied. Simultaneously, its high thermal conductivity ensures that this heat is distributed uniformly throughout the furnace chamber.

Critical Properties for the Vacuum Environment

A material's performance in a vacuum is defined by more than just heat resistance. Graphite's other characteristics are essential for maintaining process purity and integrity.

Extremely Low Vapor Pressure

To maintain a high-quality vacuum, all internal components must have low vapor pressure. Graphite releases very few particles even at extreme temperatures, preventing contamination of the vacuum atmosphere and the product being heat-treated.

High Chemical Inertness

Graphite is chemically stable and does not react with most materials. This ensures that the furnace components will not contaminate the parts being processed, which is critical in industries like electronics and aerospace.

Ease of Machining

Despite its strength, graphite can be easily machined into complex shapes. This allows for the creation of custom-designed heating elements, fixtures, and product carriers tailored to specific furnace requirements, maximizing efficiency and performance.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging graphite's limitations is key to using it effectively and maximizing its service life.

Susceptibility to Oxidation

Graphite's incredible high-temperature performance is only valid in a vacuum or an inert gas atmosphere. When exposed to oxygen at high temperatures, it will rapidly oxidize (burn), leading to material loss and component failure.

The Role of Protective Coatings

To mitigate oxidation, especially during brief exposures to air when the furnace is hot, graphite components are often treated with protective coatings. A silicon carbide (SiC) coating is common, forming a protective layer that extends the life of the part.

Brittleness and Handling Care

While graphite has high compressive strength, it is a brittle material, not a ductile metal. It can chip or crack if dropped or subjected to sharp impacts. Careful handling is always required during installation and maintenance.

Making the Right Choice for Your Application

Selecting and specifying graphite components depends on your primary operational goal.

- If your primary focus is operational efficiency and cost: The combination of graphite's lightweight nature for easy handling and its long service life for reduced downtime makes it the superior choice.

- If your primary focus is process performance and purity: Graphite's chemical inertness, low vapor pressure, and ability to provide uniform heating are its most critical advantages.

- If your primary focus is rapid cycle times: Its outstanding thermal shock resistance is the key property, allowing for aggressive heating and cooling profiles without risking component failure.

Ultimately, graphite's distinct combination of properties makes it a uniquely enabling material for modern high-temperature vacuum processing.

Summary Table:

| Key Advantage | Impact on Vacuum Furnace Operation |

|---|---|

| Lightweight | Easier installation, reduced labor, and minimized structural wear. |

| High Strength | Supports large components, withstands thermal stress, and extends furnace life. |

| Thermal Stability | Operates stably up to 3000°C, ideal for extreme heat treatment processes. |

| Chemical Inertness | Prevents contamination, ensuring high-purity results for sensitive applications. |

| Thermal Shock Resistance | Allows rapid heating/cooling cycles without cracking or degradation. |

Optimize your vacuum furnace performance with KINTEK's advanced graphite solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace components tailored to your unique needs. Our expertise in graphite ensures you benefit from lower operational costs, enhanced safety, and unmatched thermal stability.

Contact us today to discuss how our custom heating elements, fixtures, and insulation can elevate your high-temperature processes!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- How does vacuum heat treating affect the grain structure of metal alloys? Achieve Precise Microstructure Control