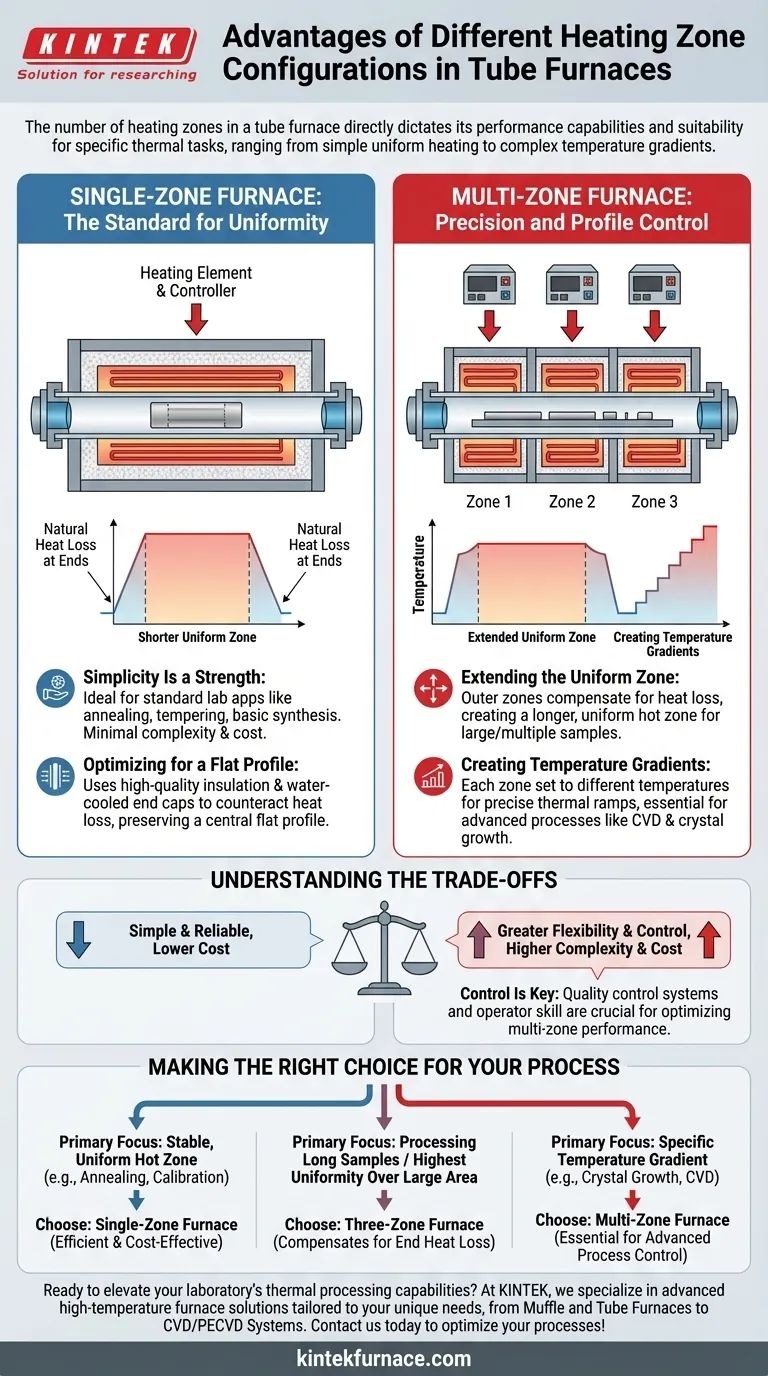

The number of heating zones in a tube furnace directly dictates its performance capabilities and suitability for a specific task. A single-zone furnace is designed for creating one stable, uniform temperature area, making it ideal for simple heat treatment. In contrast, multi-zone furnaces use two, three, or more independent heaters to either extend the length of that uniform zone or create a precise, complex temperature gradient along the tube's length.

The choice between a single-zone and a multi-zone furnace is not about which is "better," but which one matches your specific thermal requirements. The core decision hinges on whether you need simple, broad uniformity or precise control over the temperature profile along the length of your sample.

The Single-Zone Furnace: The Standard for Uniformity

A single-zone furnace is the most common and straightforward configuration, built around a single heating element and controller. Its primary goal is to create one consistent and stable hot zone in the center of the tube.

When Simplicity Is a Strength

For many standard laboratory applications, such as annealing, tempering, and basic material synthesis, a single, reliable temperature is all that is required. A single-zone furnace provides this with minimal complexity and cost.

The Challenge of Heat Loss

The main limitation of a single-zone furnace is natural heat loss at the ends of the tube. This means the truly uniform temperature zone is always shorter than the heated length of the furnace itself.

Optimizing for a Flat Profile

To counteract heat loss and maximize the uniform zone, single-zone furnaces often employ high-quality insulation and may incorporate features like water-cooled end caps. These additions help create a sharper temperature drop-off at the ends, preserving a flatter, more uniform profile in the center.

The Multi-Zone Furnace: Precision and Profile Control

Multi-zone furnaces divide the heated length into multiple, independently controlled sections. This design unlocks a much higher degree of thermal control and flexibility. Three-zone configurations are the most common, but furnaces with two or more zones exist for specialized tasks.

Extending the Uniform Zone

A key advantage of a three-zone furnace is its ability to create a longer and more uniform hot zone than a single-zone furnace of the same length. By setting the two outer (end) zones to a slightly higher temperature, you can directly compensate for heat loss at the ends.

This creates a significantly larger flat-profile hot zone in the center, which is critical for processing larger samples or multiple smaller samples that must all experience the exact same temperature.

Creating Temperature Gradients

The most powerful feature of a multi-zone furnace is its ability to create a controlled temperature gradient. Each zone can be set to a different temperature, establishing a precise thermal ramp along the tube.

This capability is essential for advanced processes like chemical vapor deposition (CVD) and crystal growth, where different stages of a reaction must occur at specific, distinct temperatures within the same process.

Understanding the Trade-offs

Choosing a furnace configuration requires balancing performance needs with practical constraints. More zones offer more control but also introduce new complexities.

Cost and Complexity

Multi-zone furnaces are inherently more expensive due to the additional heating elements, power controllers, and thermocouples required. Programming and operation are also more complex, demanding a greater understanding of the system's thermal dynamics.

Flexibility vs. Simplicity

A single-zone furnace is optimized for one task: creating a uniform hot zone. It is simple to operate and highly reliable for that purpose. A multi-zone furnace offers far more flexibility but requires careful setup to achieve its potential.

Control Is Key

A poorly programmed multi-zone furnace can easily produce a less uniform temperature profile than a well-designed single-zone model. The quality of the control system and the operator's skill are just as important as the number of heating zones.

Making the Right Choice for Your Process

Your application's specific thermal requirements should be the only factor that guides your decision.

- If your primary focus is creating a stable, uniform hot zone for processes like annealing or calibration: A single-zone furnace is the most efficient and cost-effective solution.

- If your primary focus is processing long samples or achieving the highest possible uniformity over a large area: A three-zone furnace, programmed to compensate for heat loss at the ends, is the superior choice.

- If your primary focus is creating a specific temperature gradient for processes like crystal growth or CVD: A multi-zone furnace is essential for this level of advanced process control.

By matching the zone configuration to your thermal profile needs, you ensure both the accuracy of your results and the efficiency of your operation.

Summary Table:

| Configuration | Key Advantages | Ideal Applications |

|---|---|---|

| Single-Zone | Uniform temperature, cost-effective, simple operation | Annealing, tempering, basic material synthesis |

| Multi-Zone | Extended uniform zone, precise temperature gradients, flexibility | Chemical vapor deposition (CVD), crystal growth, large sample processing |

Ready to elevate your laboratory's thermal processing capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer a comprehensive product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your experimental requirements, whether you need a simple single-zone furnace for uniform heating or a multi-zone system for complex gradients. Don't settle for less—contact us today to discuss how we can optimize your processes and deliver reliable, high-performance results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation