At their core, retort furnaces are used for any high-temperature thermal process that requires absolute control over the atmospheric environment. Specific applications include the bright annealing of stainless steel, heat treating reactive metals like titanium, furnace brazing, and the sintering of advanced powders and ceramics for industries ranging from metallurgy to electronics.

The defining feature of a retort furnace is not just its ability to generate heat, but its use of a sealed inner chamber—the retort. This design isolates the workload from the furnace's heating elements, enabling precise control over the gas atmosphere (or vacuum) to prevent unwanted chemical reactions like oxidation.

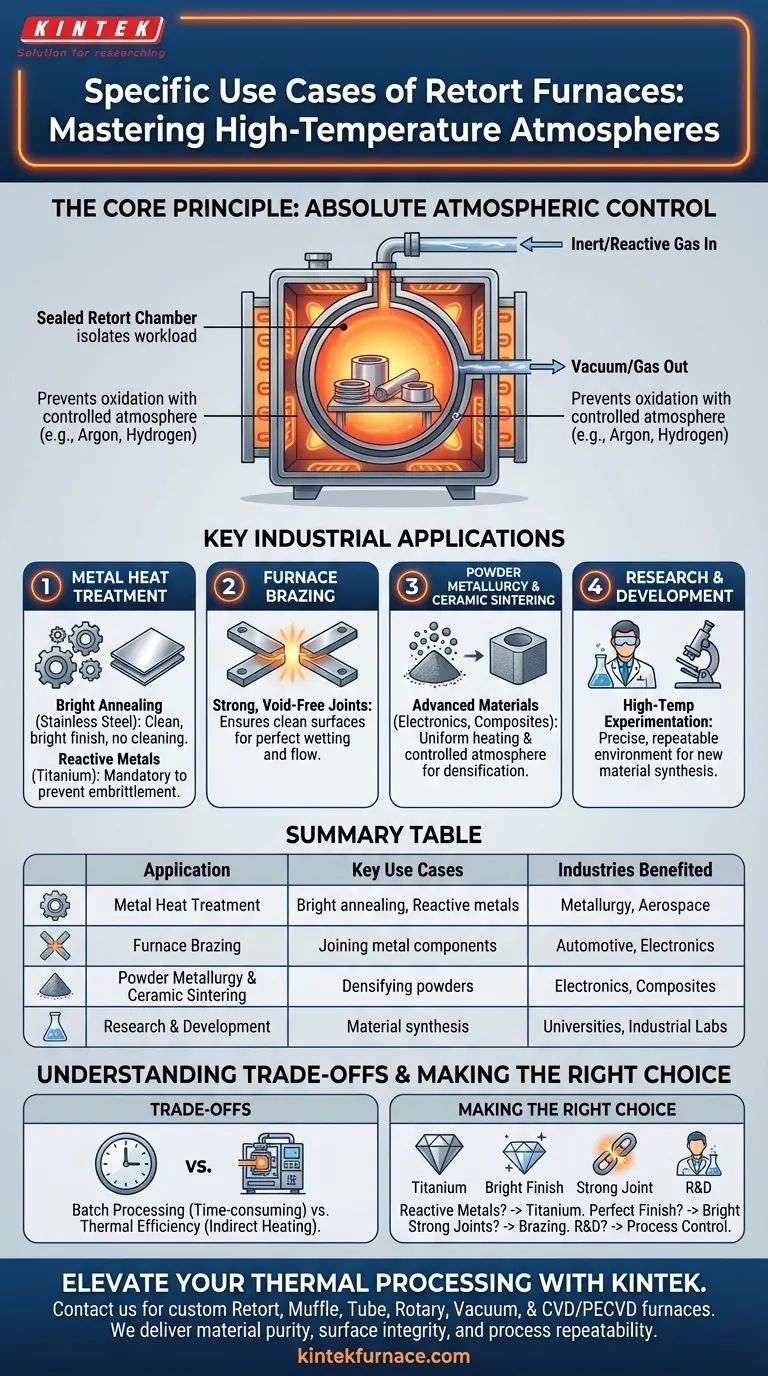

The Core Principle: Absolute Atmospheric Control

The value of a retort furnace is rooted in its ability to create a highly specific, controlled environment, which is impossible to achieve in a standard open-air or direct-fired furnace.

The Sealed Retort Chamber

A retort is a metallic or ceramic container that is sealed to be gas-tight. Your parts are placed inside this retort, which is then placed inside the main furnace for heating.

This separation is the key. It allows you to introduce specific gases—like nitrogen, argon, or hydrogen—or pull a vacuum inside the retort, creating an environment tailored to your process needs.

Why Atmosphere Is Critical

At high temperatures, most materials become highly reactive. The oxygen present in normal air will rapidly cause oxidation (scaling or rust), which can ruin the surface finish, mechanical properties, and integrity of a part.

Controlled atmospheres prevent this. An inert gas like argon displaces oxygen, while a reactive gas like hydrogen can actively remove surface oxides, a process essential for "bright" finishing.

Key Industrial Applications

The principle of atmospheric control makes retort furnaces indispensable for processes where material purity and surface integrity are paramount.

Metal Heat Treatment

Retort furnaces excel at annealing, hardening, and brazing. They are particularly vital for bright annealing stainless steel parts, where an inert or reducing atmosphere prevents surface scaling, resulting in a clean, bright finish that requires no post-process cleaning.

For reactive metals like titanium, which readily absorb oxygen at high temperatures causing embrittlement, a retort furnace providing a vacuum or pure argon atmosphere is not just beneficial—it's mandatory.

Furnace Brazing

When joining metal components with a filler metal, any oxidation on the surfaces will prevent the braze alloy from wetting and flowing properly. A retort furnace ensures the entire assembly remains perfectly clean throughout the heating cycle, resulting in strong, void-free joints.

Powder Metallurgy and Ceramic Sintering

Creating dense, high-performance parts from metal or ceramic powders requires heating them to just below their melting point. A retort furnace provides the uniform heating and controlled atmosphere needed to prevent powder oxidation and ensure proper densification. This is essential for producing advanced materials for electronics and composites.

The Role in Research and Development

Universities, research institutes, and industrial labs rely heavily on retort furnaces for their precision and versatility.

High-Temperature Experimentation

When synthesizing new materials or studying chemical reactions at high temperatures, scientists need to eliminate as many variables as possible. A retort furnace provides a repeatable, precisely controlled environment to ensure experimental results are valid and reliable.

Understanding the Trade-offs

While powerful, retort furnaces are not the universal solution for all heating applications. Understanding their limitations is key to using them effectively.

Batch Processing and Throughput

Most standard retort furnaces are designed for batch processing. Loading, sealing, purging the atmosphere, running the cycle, and cooling can take significant time, limiting throughput compared to continuous belt furnaces.

Rotary retort furnaces are an exception, designed to process large quantities of small parts (like fasteners) in a more continuous fashion.

Thermal Efficiency and Complexity

Heating a workload inside a secondary chamber (the retort) is inherently less direct and can be less energy-efficient than heating parts directly. The systems required for sealing, purging gas, or pulling a vacuum also add mechanical complexity and cost compared to simpler furnace designs.

Making the Right Choice for Your Process

Your choice of thermal processing equipment should be driven by the specific demands of your material and desired outcome.

- If your primary focus is processing reactive metals like titanium: The absolute atmospheric control of a retort furnace is non-negotiable to prevent catastrophic material degradation.

- If your primary focus is achieving a perfect, clean surface finish on stainless steel: A retort furnace for bright annealing is the correct choice to avoid costly and damaging post-processing steps.

- If your primary focus is high-strength, void-free brazed joints: Use a retort furnace to ensure pristine cleanliness of the base and filler metals throughout the heating cycle.

- If your primary focus is R&D or powder material synthesis: A retort furnace provides the essential process control and repeatability required for developing and producing advanced materials.

Ultimately, a retort furnace is the definitive tool when the environment your part is heated in is just as important as the temperature itself.

Summary Table:

| Application | Key Use Cases | Industries Benefited |

|---|---|---|

| Metal Heat Treatment | Bright annealing of stainless steel, heat treating reactive metals like titanium | Metallurgy, Aerospace |

| Furnace Brazing | Joining metal components with strong, void-free joints | Automotive, Electronics |

| Powder Metallurgy & Ceramic Sintering | Densifying powders for advanced materials | Electronics, Composites |

| Research & Development | High-temperature experiments for material synthesis | Universities, Industrial Labs |

Ready to elevate your thermal processing with precise atmospheric control? Contact KINTEK today to discuss how our advanced retort furnaces—part of our diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—can be customized to meet your unique needs. Leveraging exceptional R&D and in-house manufacturing, we deliver solutions that ensure material purity, surface integrity, and process repeatability for industries like metallurgy and electronics. Get in touch now to optimize your high-temperature applications!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance