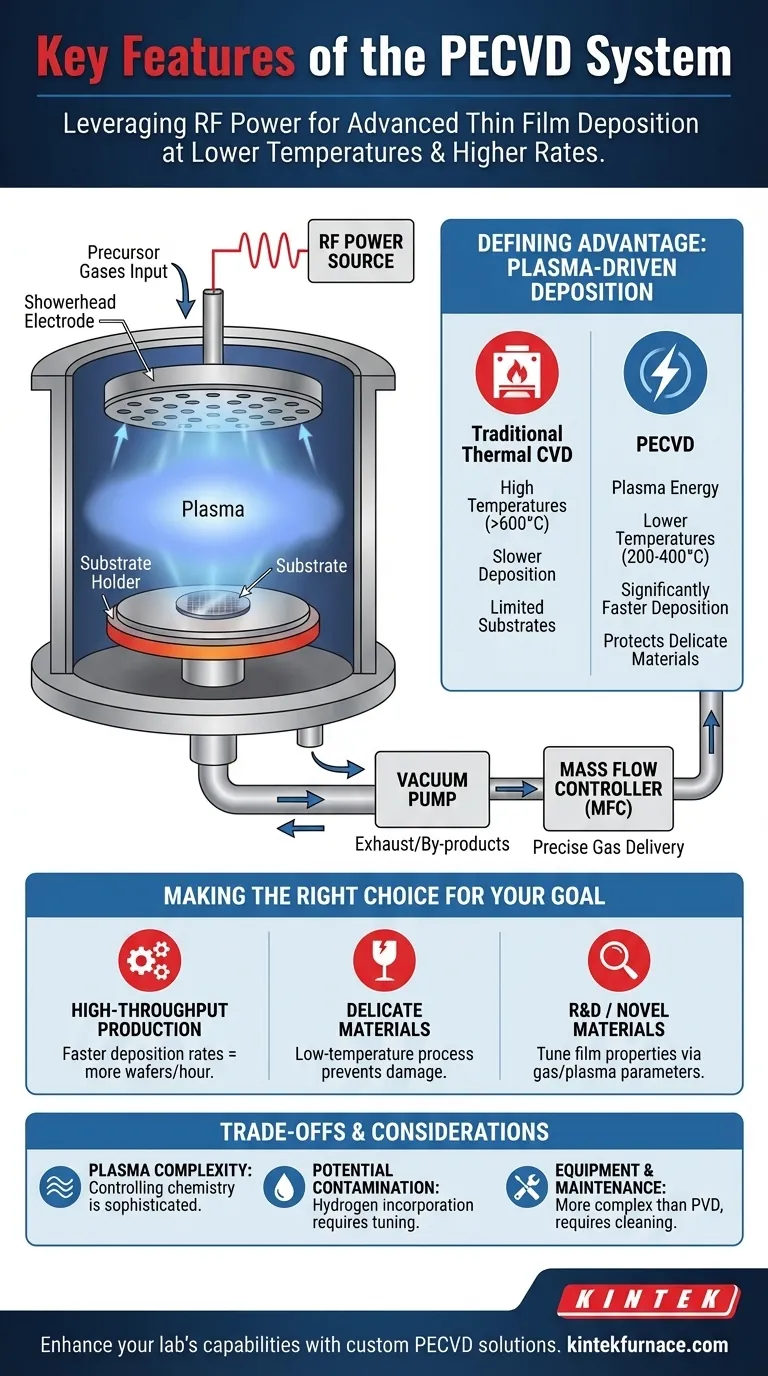

At its core, a Plasma-Enhanced Chemical Vapor Deposition (PECVD) system is defined by its use of a radio frequency (RF) power source to generate plasma within a vacuum chamber. Key features include precisely controlled gas delivery, heated electrodes to hold the substrate, and a vacuum system. These components work together to enable the deposition of thin films at significantly lower temperatures and higher rates than conventional methods.

The most critical feature of PECVD is not the hardware itself, but its function: using the energy from a plasma rather than high heat to drive chemical reactions. This fundamental difference unlocks the ability to create high-quality films on materials that could not survive traditional high-temperature processes.

Deconstructing the Core Components

A PECVD system is an integrated set of subsystems, each with a specific role. While exact specifications vary by manufacturer, the fundamental building blocks are universal.

The Process Chamber and Electrodes

The reaction occurs within a vacuum chamber. This chamber houses a set of electrodes, often in a parallel-plate configuration.

One electrode, typically the lower one, serves as a heated platen to hold the substrate (the wafer or sample being coated). The other electrode, often a "showerhead" design, introduces the precursor gases uniformly across the substrate's surface.

The RF Power Source

This is the component that puts the "Plasma-Enhanced" in PECVD. A radio frequency (RF) power source is connected to the electrodes.

When activated, the RF energy excites the precursor gases between the electrodes, igniting them into a plasma. This plasma is a partially ionized gas containing highly reactive species that are essential for the deposition process.

The Gas Delivery and Vacuum Systems

A PECVD system requires a precise gas delivery system, often a "gas pod" with multiple lines. Each line is governed by a mass flow controller (MFC) to ensure the exact mixture and volume of precursor gases enter the chamber.

A powerful vacuum pump creates the low-pressure environment needed for plasma to form and for the chemical reactions to proceed cleanly. An exhaust system removes the unreacted gases and by-products.

The Defining Advantage: Plasma-Driven Deposition

The use of plasma fundamentally changes the deposition process, providing advantages that are impossible to achieve with purely thermal methods like traditional Chemical Vapor Deposition (CVD).

Overcoming Temperature Limitations

In traditional CVD, extremely high temperatures (often >600°C) are required to provide enough thermal energy to break down the precursor gas molecules.

PECVD replaces most of this thermal energy with energy from the plasma. This allows deposition to occur at much lower temperatures (typically 200-400°C), protecting delicate substrates like polymers or previously fabricated integrated circuits from thermal damage.

Achieving High Deposition Rates

The highly reactive species created in the plasma cause the film-forming chemical reactions to happen much more quickly.

This results in significantly faster deposition rates compared to other methods. For example, silicon nitride deposition via PECVD can be over 100 times faster than with conventional low-pressure CVD (LPCVD).

Ensuring Film Uniformity and Quality

The showerhead gas inlet is engineered to distribute gas evenly, and the plasma itself tends to fill the space between the electrodes uniformly. This combination produces films with excellent thickness uniformity across the entire substrate.

Furthermore, the plasma process can result in dense, high-quality films with good adhesion and a reduced risk of cracking.

Understanding the Trade-offs and Considerations

While powerful, PECVD is not without its complexities. Understanding its limitations is key to successful implementation.

Plasma Complexity

The plasma that provides the system's key advantages is also its greatest complexity. Controlling plasma chemistry is a sophisticated task, as small changes in pressure, power, or gas mixture can significantly alter the resulting film's properties.

Potential for Contamination

Many precursor gases used in PECVD contain hydrogen. In some processes, this hydrogen can become incorporated into the deposited film, which can affect its electrical or optical properties. This requires careful process tuning to minimize.

Equipment and Maintenance

While some systems are designed for easy operation, PECVD equipment is inherently more complex than a simpler Physical Vapor Deposition (PVD) system. The chamber requires periodic cleaning to remove built-up deposits, and the RF and vacuum systems add to the maintenance overhead.

Making the Right Choice for Your Goal

The features of PECVD make it uniquely suited for specific applications. Your primary goal should guide your evaluation of the technology.

- If your primary focus is high-throughput production: The exceptionally high deposition rates are the most critical feature, enabling more wafers per hour.

- If your primary focus is coating delicate or temperature-sensitive materials: The low-temperature processing capability is the defining advantage that makes your application possible.

- If your primary focus is R&D or creating novel materials: The ability to tune film properties by adjusting gas chemistry and plasma parameters offers unparalleled flexibility.

Ultimately, the features of PECVD provide a powerful and versatile toolkit for advanced material deposition.

Summary Table:

| Feature | Description |

|---|---|

| Plasma-Enhanced Deposition | Uses RF power to create plasma for chemical reactions, enabling low-temperature processing and high deposition rates. |

| Low-Temperature Operation | Deposits films at 200-400°C, ideal for delicate substrates like polymers and integrated circuits. |

| High Deposition Rates | Achieves significantly faster film growth, e.g., over 100x faster than LPCVD for silicon nitride. |

| Uniform Film Quality | Ensures excellent thickness and quality across substrates via showerhead gas delivery and plasma uniformity. |

| Precise Gas and Vacuum Control | Incorporates mass flow controllers and vacuum systems for accurate gas mixtures and clean environments. |

Ready to enhance your lab's capabilities with advanced PECVD systems? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace solutions, including PECVD/CVD Systems. Our strong deep customization capability precisely meets your unique experimental needs for low-temperature, high-rate thin film deposition. Contact us today to discuss how we can optimize your processes and drive innovation in your research or production!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods