In industrial settings, rotary furnaces are used for a range of critical physicochemical processes that require both high temperatures and continuous mixing. Key examples include the gaseous reduction of ores, the thermal decomposition of materials through calcination, the synthesis of catalysts and pigments, and modifying material properties through oxidation or doping.

The true value of a rotary furnace lies in its unique ability to combine heat with constant tumbling motion. This ensures that every particle of the material is uniformly heated and exposed to the furnace's atmosphere, which is essential for achieving a complete and consistent chemical transformation.

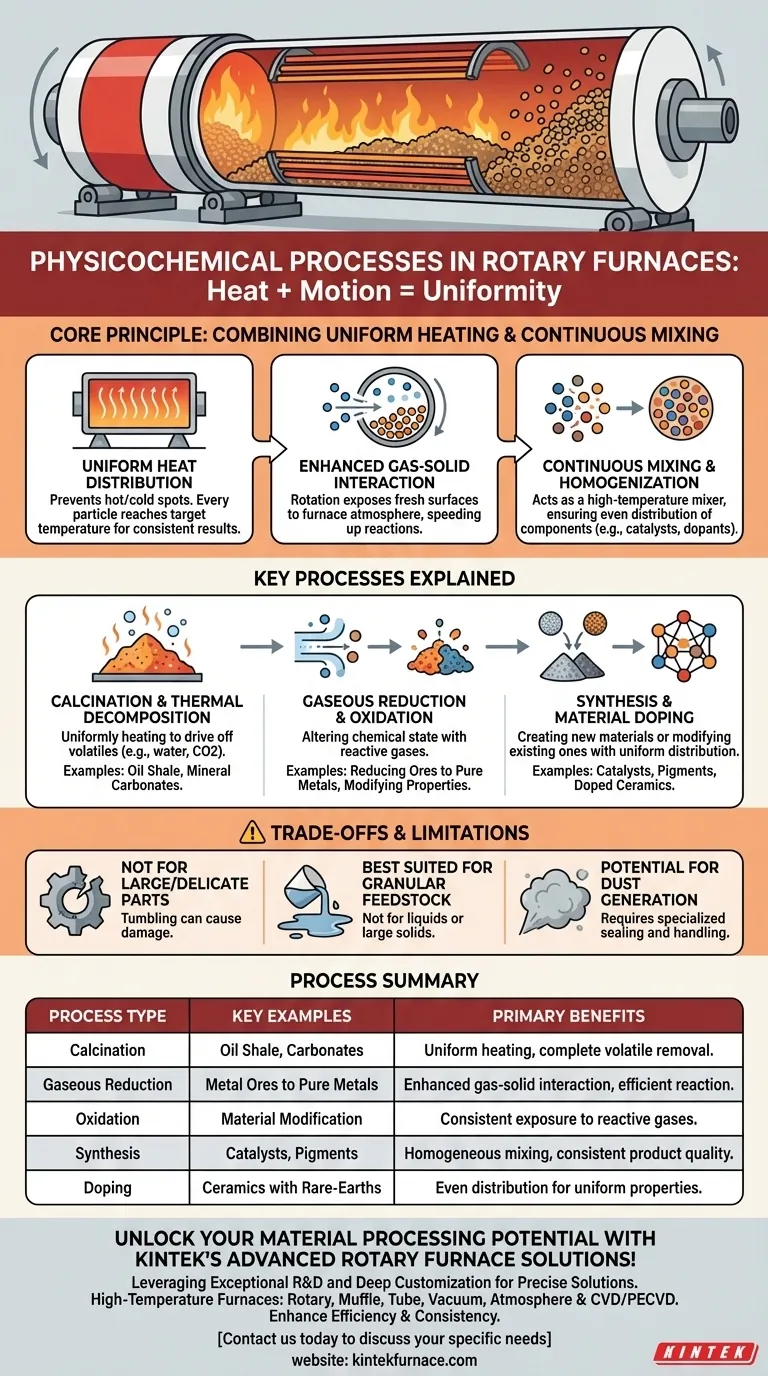

The Core Principle: Heat Meets Motion

Unlike static furnaces, the rotary design introduces a mechanical element—rotation—that fundamentally changes how heat and reactants interact with the material being processed. This combination is the reason it is selected for specific industrial tasks.

Uniform Heat Distribution

The constant tumbling of the material bed prevents the formation of hot or cold spots. This ensures that the entire batch reaches and maintains the target temperature, leading to a highly consistent and predictable final product.

Enhanced Gas-Solid Interaction

Many processes, like reduction and oxidation, depend on a reaction between a solid material and a gas. The rotation continuously exposes fresh surfaces of the particles to the reactive gases in the furnace atmosphere, dramatically increasing the efficiency and speed of the reaction.

Continuous Mixing and Homogenization

For processes like synthesis or doping, achieving a perfectly uniform mixture is paramount. The rotary action acts as a high-temperature mixer, ensuring that all components, such as a ceramic base and a rare-earth dopant, are distributed evenly.

Key Physicochemical Processes Explained

The unique capabilities of rotary furnaces make them ideal for several specific applications where material uniformity is critical.

Calcination and Thermal Decomposition

Calcination is a process of heating a solid to a high temperature to induce thermal decomposition, often to drive off a volatile component like water or carbon dioxide. The uniform heating in a rotary furnace ensures that this decomposition is complete throughout the material, as seen in the calcination of oil shale to release hydrocarbons or the processing of mineral carbonates.

Gaseous Reduction and Oxidation

These processes alter the chemical state of a material by reacting it with a controlled atmosphere. In the gaseous reduction of ores, a reducing gas removes oxygen from metal oxides to yield the pure metal. The furnace's rotation is crucial for ensuring the gas reaches every particle, driving the reaction to completion. Oxidation achieves the opposite effect, and the same principle applies.

Synthesis and Material Doping

Rotary furnaces are used to create entirely new materials or modify existing ones. When synthesizing catalysts or pigments, the constant mixing at high temperatures ensures a chemically homogeneous product with consistent performance. Similarly, when doping ceramics with rare-earth metals to alter their properties, the rotation guarantees the dopant is evenly integrated into the ceramic matrix.

Understanding the Trade-offs

While powerful, the rotary furnace is a specialized tool, and its design comes with specific limitations that make it unsuitable for certain applications.

Not for Large or Delicate Parts

The tumbling action that is so beneficial for powders and granular materials would damage or destroy large, single components or delicate structures. For these applications, a static box furnace is the appropriate choice.

Best Suited for Granular Feedstock

Rotary furnaces are designed to process materials that can flow and tumble, such as powders, grains, pellets, and small ores. They are not effective for processing liquids or large, irregularly shaped solids.

Potential for Dust Generation

The mechanical tumbling of fine powders can generate significant dust. This often requires specialized seals and off-gas handling systems to ensure safe operation and prevent material loss.

Making the Right Choice for Your Goal

Selecting the correct furnace technology hinges on the nature of your material and the transformation you need to achieve.

- If your primary focus is transforming powders, ores, or grains: A rotary furnace is the superior choice for processes like calcination, reduction, and synthesis that demand exceptional uniformity.

- If your primary focus is heat-treating a single, solid component: A static box or chamber furnace is necessary to process the part without causing mechanical damage from tumbling.

- If your primary focus is creating a perfectly homogeneous composite material: The continuous mixing action of a rotary furnace is ideal for ensuring even distribution of components, such as when doping ceramics or synthesizing catalysts.

By understanding the fundamental interplay of heat and motion, you can confidently select the right thermal processing technology for your specific objective.

Summary Table:

| Process Type | Key Examples | Primary Benefits |

|---|---|---|

| Calcination | Thermal decomposition of oil shale, mineral carbonates | Uniform heating, complete volatile removal |

| Gaseous Reduction | Reduction of metal ores to pure metals | Enhanced gas-solid interaction, efficient reaction |

| Oxidation | Material property modification via oxidation | Consistent exposure to reactive gases |

| Synthesis | Catalyst and pigment creation | Homogeneous mixing, consistent product quality |

| Doping | Ceramic modification with rare-earth metals | Even distribution of dopants for uniform properties |

Unlock the full potential of your material processing with KINTEK's advanced rotary furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Rotary, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and product consistency. Contact us today to discuss how we can tailor a furnace to your specific physicochemical processes!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control