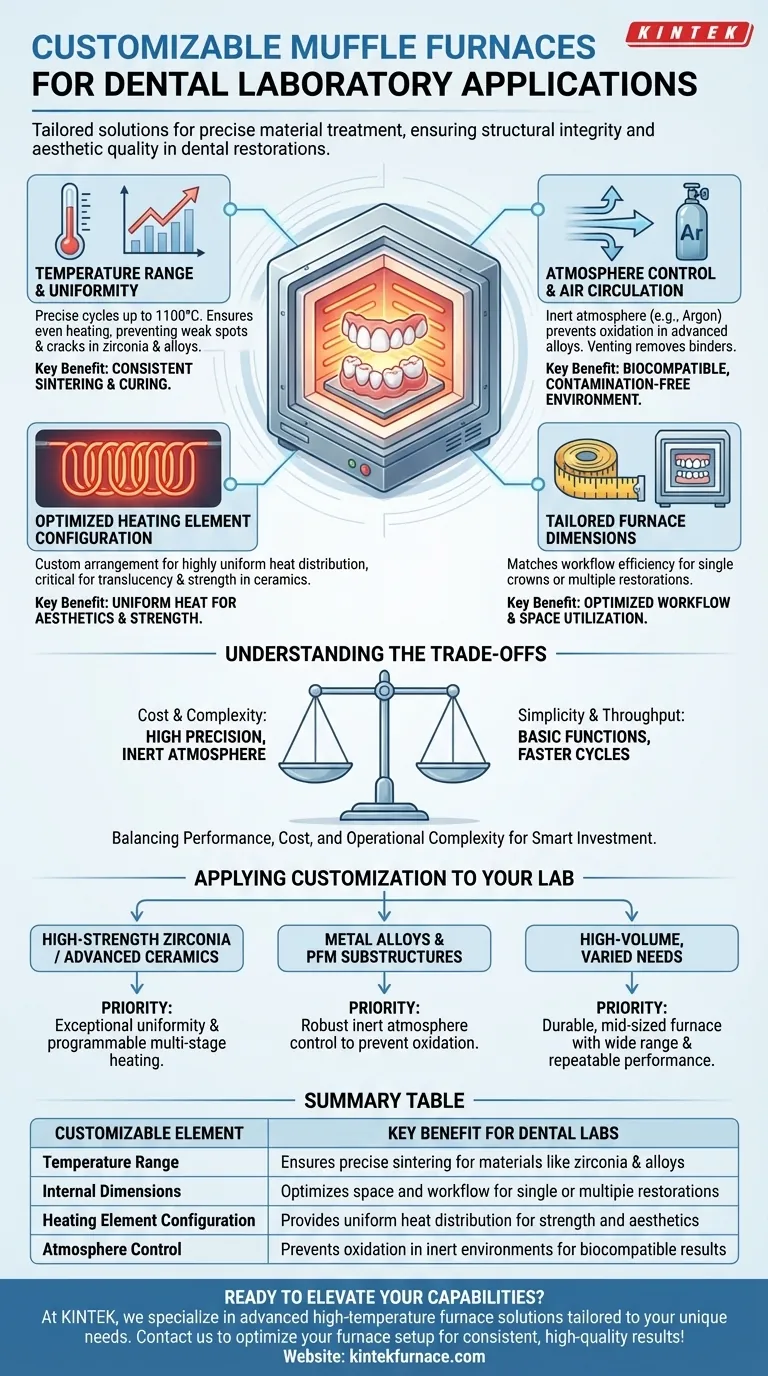

For dental laboratory applications, the primary customizable elements of a muffle furnace are its temperature range, internal dimensions, heating element configuration, and air circulation or atmosphere control. These features are adjusted to meet the highly specific material requirements for creating dental restorations such as crowns, bridges, and dentures, ensuring both structural integrity and aesthetic quality.

The goal of customizing a muffle furnace is not simply to change its specifications, but to precisely control the heat treatment environment. This control is what enables a dental lab to achieve consistent, high-quality results across a wide range of sensitive dental materials.

Why Customization Matters for Dental Restorations

A muffle furnace works by isolating materials inside a protective chamber, or "muffle," preventing direct contact with heating elements or combustion gases. This ensures a clean, contamination-free environment, which is non-negotiable for producing medical-grade dental prosthetics. Customization allows a lab to tailor this environment for specific processes and materials.

Controlling Temperature Range and Uniformity

The specific materials used in crowns and bridges, such as zirconia or certain metal alloys, require exacting temperature cycles for proper sintering and curing. A furnace with a customizable temperature range (often up to 1100°C) and excellent uniformity ensures that the entire restoration heats evenly, preventing weak spots or cracks.

Optimizing Heating Elements and Formation

The arrangement of the heating elements inside the furnace dictates how quickly and evenly the chamber heats up. A custom formation can be designed to create highly uniform heat distribution, which is critical for achieving the desired translucency and strength in ceramic materials.

Tailoring Furnace Dimensions

The internal dimensions of the furnace must match the lab's workflow. A small lab creating single crowns needs a different size than a large lab processing multiple bridges simultaneously. Customizing the size ensures optimal energy efficiency and space utilization.

Managing Atmosphere and Air Circulation

This is one of the most critical customizations. Many advanced dental alloys must be processed in an inert atmosphere (like argon) to prevent oxidation, which can compromise the material's strength and biocompatibility. Proper air circulation or venting is also key for removing binders during the initial heating phase of sintering.

Understanding the Trade-offs

Choosing the right features involves balancing performance with cost and operational complexity. Understanding these trade-offs is key to making a sound investment.

Precision vs. Cost

Features like inert atmosphere control and exceptionally uniform temperature zones significantly increase a furnace's cost. Labs must weigh this investment against the types of high-value restorations they produce. A standard furnace may be sufficient for basic tasks, but inadequate for advanced alloys.

Speed vs. Material Integrity

While faster heating cycles can increase a lab's throughput, they can also introduce thermal shock to sensitive ceramic materials, leading to micro-fractures. The ideal furnace allows for programmable heating rates that balance speed with the safe processing limits of the material.

Contamination Control vs. Simplicity

The muffle design inherently prevents most contamination. However, furnaces designed for ultra-pure applications or reactive metals have superior sealing and atmosphere control, adding complexity. This level of control is essential for some materials but may be overkill for others.

How to Apply This to Your Laboratory

Your choice should be dictated by the primary function the furnace will serve in your lab.

- If your primary focus is high-strength zirconia or advanced ceramics: Prioritize a furnace with exceptional temperature uniformity and programmable, multi-stage heating cycles.

- If your primary focus is processing metal alloys or PFM substructures: Invest in a furnace with robust inert atmosphere control to prevent oxidation.

- If you run a high-volume lab with varied needs: Select a durable, mid-sized furnace with a wide temperature range and reliable, repeatable performance for general-purpose work.

Ultimately, aligning the furnace's capabilities with your specific material and production needs is the key to maximizing your return on investment.

Summary Table:

| Customizable Element | Key Benefit for Dental Labs |

|---|---|

| Temperature Range | Ensures precise sintering for materials like zirconia and alloys |

| Internal Dimensions | Optimizes space and workflow for single or multiple restorations |

| Heating Element Configuration | Provides uniform heat distribution for strength and aesthetics |

| Atmosphere Control | Prevents oxidation in inert environments for biocompatible results |

Ready to elevate your dental laboratory's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, and Vacuum & Atmosphere Furnaces, with deep customization to ensure precise temperature control, uniform heating, and contamination-free environments for superior dental restorations. Don't settle for less—contact us today to discuss how we can optimize your furnace setup for consistent, high-quality results!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance