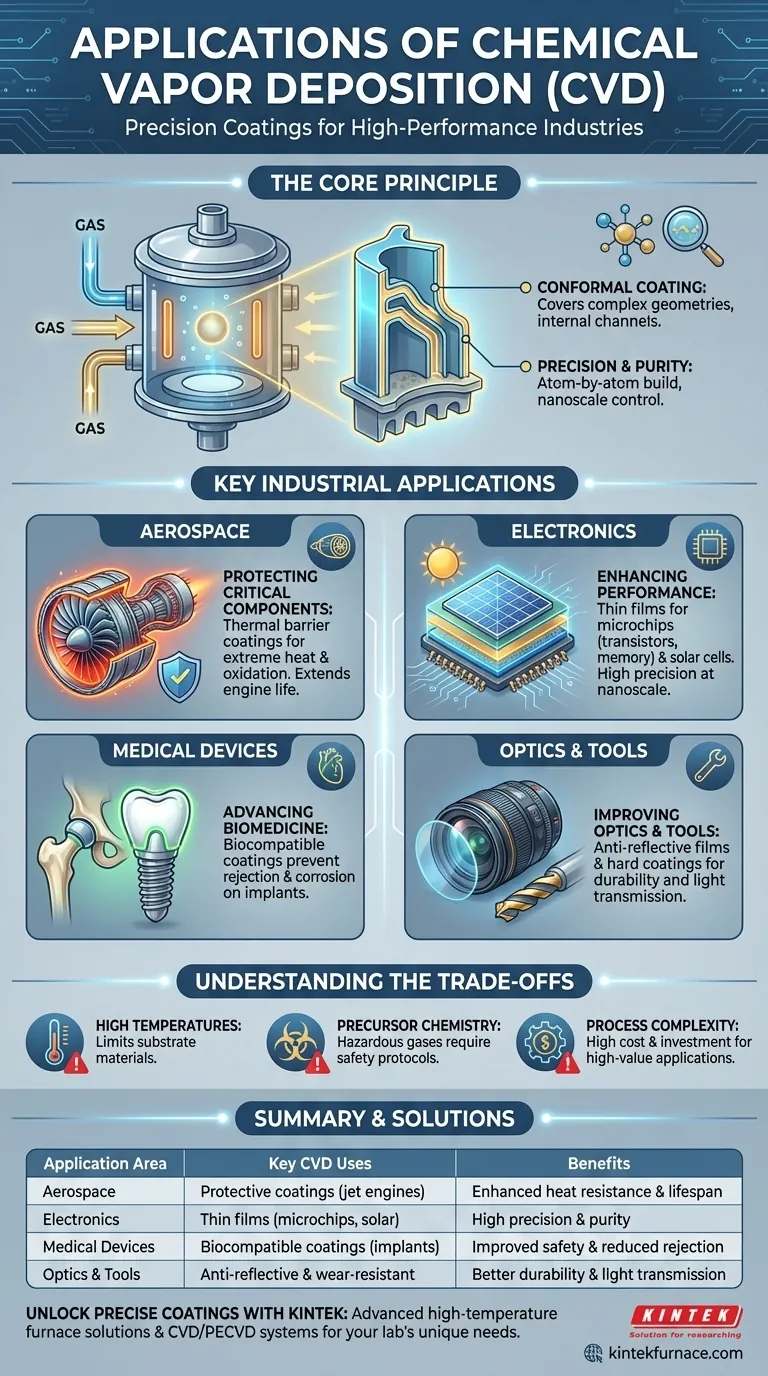

From aerospace to medicine, Chemical Vapor Deposition (CVD) is a foundational technology for creating high-performance coatings across a vast range of industries. It is used to apply protective layers on jet engine components, create biocompatible surfaces on medical implants, deposit anti-reflective films on optical lenses, and fabricate the critical layers in microchips and solar cells.

The true value of CVD lies not just in applying a coating, but in its precision. The process allows for the creation of highly pure, exceptionally uniform, and conformal thin films onto complex surfaces, fundamentally enhancing the performance and longevity of the underlying material.

The Core Principle: Why CVD is So Versatile

CVD is a process that goes far beyond simply "painting" a surface. It involves a chemical transformation that builds a new material, molecule by molecule, directly onto a substrate.

What is Chemical Vapor Deposition?

The process begins by introducing one or more volatile precursor gases into a reaction chamber, which is often under vacuum.

The chamber is heated to a specific temperature, causing the precursor gases to react or decompose. This chemical reaction results in the formation of a solid material that deposits onto the substrate, creating a thin, solid film.

The Advantage of Conformal Coating

Unlike line-of-sight methods like sputtering, CVD gases can flow around and into complex geometries.

This results in a conformal coating—a film of uniform thickness that covers every surface, including intricate internal channels, sharp corners, and complex 3D shapes.

Precision and Purity at the Nanoscale

CVD provides exceptional control over the film's thickness and composition. By carefully managing gas flow rates, temperature, and pressure, engineers can create films with high purity and specific atomic structures.

This level of precision is critical for applications like semiconductors, where layers may be only a few atoms thick.

A Breakdown of Key Industrial Applications

The unique capabilities of CVD make it the go-to solution for challenges that demand superior surface properties.

Protecting Critical Components in Aerospace

In jet engines, turbine blades operate under extreme heat and oxidative stress. CVD is used to deposit thermal barrier coatings that protect the underlying superalloy from damage.

These coatings significantly extend the life and improve the safety of critical engine parts, preventing corrosion and wear in harsh environments.

Enhancing Performance in Electronics

CVD is indispensable in the semiconductor industry for creating the thin films that form transistors, capacitors, and interconnects in integrated circuits (microchips).

Variants like Atomic Layer Deposition (ALD) offer even greater precision for building modern processors and memory. It's also used to create the active layers in photovoltaic devices (solar cells).

Advancing Medical and Biomedical Devices

For medical implants like artificial joints or dental implants, the body's reaction to the material is paramount. CVD is used to apply biocompatible coatings.

These inert layers prevent the implant from corroding and stop the body from rejecting the foreign object. The process is also being explored for creating advanced drug-delivery systems.

Improving Optical and Industrial Tools

In optics, thin films deposited by CVD are used to create anti-reflective coatings on lenses and other optical instruments, improving light transmission and performance.

For industrial cutting tools and mechanical parts, hard, wear-resistant coatings (like titanium nitride) are applied via CVD to dramatically increase durability and lifespan.

Understanding the Trade-offs of CVD

While powerful, CVD is not a universally perfect solution. Its application involves specific requirements and limitations that must be considered.

The Requirement of High Temperatures

Traditional CVD processes often require very high temperatures to trigger the necessary chemical reactions. This can limit the types of substrate materials that can be coated, as some may melt, deform, or be otherwise damaged by the heat.

Precursor Chemistry and Safety

The precursor gases used in CVD can be volatile, toxic, or flammable, requiring sophisticated safety protocols and handling equipment. The byproducts of the reaction may also be hazardous and require careful management.

Process Complexity and Cost

A CVD setup involves vacuum chambers, high-temperature furnaces, and complex gas delivery systems. The initial investment and operational complexity can be higher than for other coating techniques, making it better suited for high-value applications.

Making the Right Choice for Your Goal

Selecting a coating technology depends entirely on the problem you are trying to solve. CVD offers a specific set of strengths tailored to demanding applications.

- If your primary focus is extreme environmental protection: CVD is the standard for creating dense, non-porous coatings that resist heat, oxidation, and corrosion.

- If your primary focus is biocompatibility: CVD can deposit inert materials that prevent adverse reactions between an implant and the body.

- If your primary focus is advanced electronics: The precision of CVD is essential for building the nanoscale structures in modern semiconductors and photovoltaics.

- If your primary focus is coating complex shapes: CVD's ability to create conformal films makes it superior to line-of-sight methods for parts with intricate geometries.

Ultimately, CVD is not just a coating process; it is a method for fundamentally re-engineering a material's surface to meet a specific functional demand.

Summary Table:

| Application Area | Key CVD Uses | Benefits |

|---|---|---|

| Aerospace | Protective coatings on jet engine components | Enhanced heat resistance and lifespan |

| Electronics | Thin films for microchips and solar cells | High precision and purity for performance |

| Medical Devices | Biocompatible coatings on implants | Improved safety and reduced rejection |

| Optics & Tools | Anti-reflective films and wear-resistant coatings | Better durability and light transmission |

Unlock the power of precise coatings for your lab with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs. Contact us today to enhance your materials' performance and longevity!

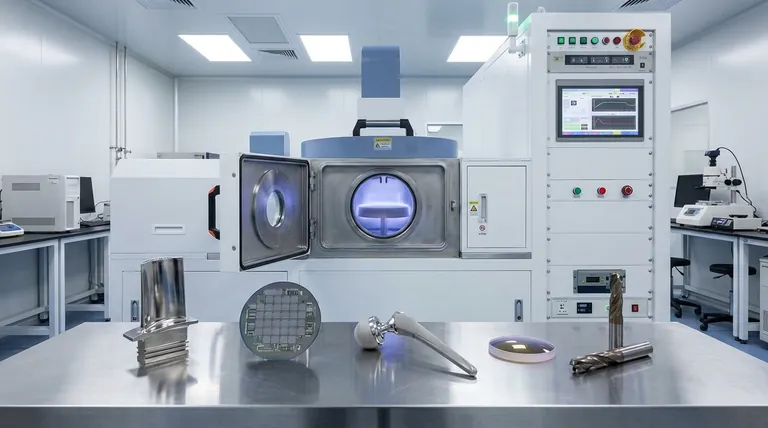

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings