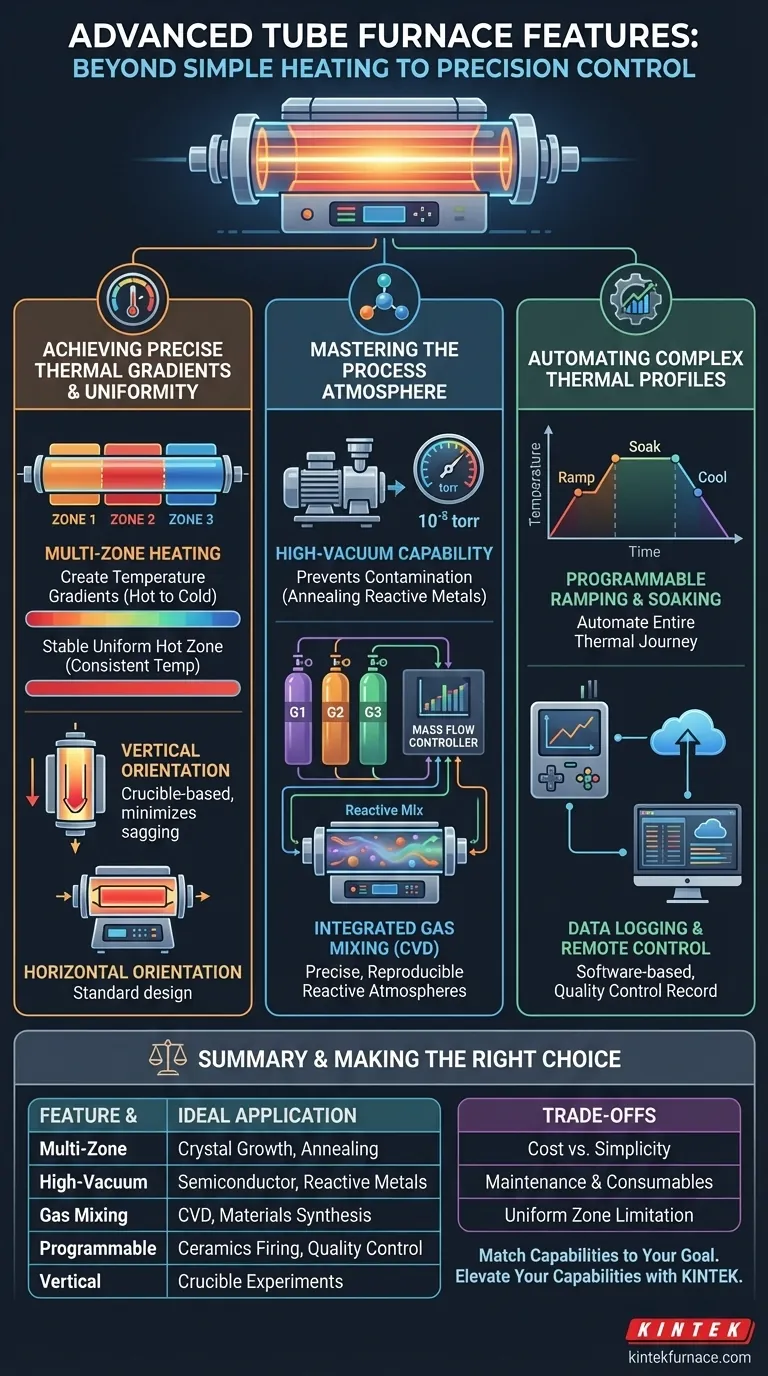

At their most advanced, tube furnaces evolve from simple heaters into precision instruments capable of sophisticated process control. The most significant advanced features include multi-zone heating for creating specific temperature profiles, advanced atmosphere control systems that support high vacuum or precise gas mixing, and fully programmable digital controllers for automating complex thermal cycles.

The core purpose of advanced tube furnace features is to move beyond simple heating and achieve unprecedented control over the processing environment. This precision is what enables reproducible, high-quality results in sensitive applications like semiconductor fabrication, crystal growth, and advanced materials research.

Achieving Precise Thermal Gradients and Uniformity

For many advanced processes, how the heat is applied is as important as the final temperature. Advanced furnaces provide granular control over the thermal landscape within the tube.

Multi-Zone Heating

A standard furnace has one heating element and one control point. An advanced furnace may have two, three, or even more independently controlled heating zones along the length of the tube.

This allows for two distinct outcomes. You can program the zones to create a stable temperature gradient, which is essential for physical vapor transport experiments where material sublimates in a hot zone and deposits in a cooler one.

Alternatively, you can set all zones to the same temperature. This overcomes the natural temperature drop-off at the ends of the tube, creating a much larger and more stable uniform hot zone in the center, which is critical for uniformly annealing larger samples.

Vertical vs. Horizontal Orientation

While most tube furnaces are horizontal, a vertical orientation is a key feature for specific applications.

In a vertical furnace, gravity can be used to your advantage, and issues like sample sagging at very high temperatures are minimized. This design is often preferred for crucible-based experiments or certain crystal growth methods.

Mastering the Process Atmosphere

Controlling the gaseous environment inside the tube is fundamental to preventing unwanted chemical reactions or, conversely, enabling desired ones.

High-Vacuum Capability

Many basic furnaces can be purged with an inert gas like argon or nitrogen. Advanced systems offer true high-vacuum capability, often down to levels of 10⁻⁵ torr or lower.

Achieving this requires upgraded flanges, seals, and an external turbomolecular pump system. This is non-negotiable for processes that are highly sensitive to oxygen or other atmospheric contaminants, such as annealing reactive metals or certain thin-film deposition techniques.

Integrated Gas Mixing Systems

For processes like Chemical Vapor Deposition (CVD), a single gas is not enough. Advanced furnaces can be equipped with mass flow controller (MFC) systems that precisely blend multiple gases.

This allows you to create highly specific reactive atmospheres, such as mixing a carrier gas with a small, controlled percentage of a precursor or reactive gas. The MFC system ensures the gas mixture is stable and reproducible run after run.

Automating Complex Thermal Profiles

The final properties of a material often depend on its entire thermal history—how it got to temperature and how it cooled down. Programmable controllers automate this entire journey.

Programmable Ramping and Soaking

Advanced digital controllers allow you to program a sequence of steps. This typically involves ramping, or changing the temperature at a controlled rate (e.g., 10°C per minute), and soaking, which is holding the temperature at a setpoint for a specific duration.

A single process might involve multiple ramp and soak segments to achieve a specific outcome, such as drying, binder burnout, and final sintering in a ceramics firing process.

Data Logging and Remote Control

Modern controllers feature digital interfaces (like RS-232 or Ethernet) that connect to a computer. This enables software-based control and data logging.

This feature is critical for quality control and research, providing a complete record of the temperature profile for each run. It also allows for remote monitoring and operation, which is essential for long processes or when integrating the furnace into a larger automated production line.

Understanding the Trade-offs

While powerful, these advanced features introduce complexity and cost that are not always necessary.

Cost vs. Simplicity

A multi-zone, high-vacuum furnace with a gas mixing system can cost several times more than a simple single-zone furnace. For straightforward applications like basic heat treating or drying, the added complexity is an unnecessary expense and a potential point of failure.

Maintenance and Consumables

High-vacuum systems require regular maintenance of pumps, seals, and gauges. Gas mixing systems consume process gases and require periodic calibration of the mass flow controllers. These operational costs must be factored into the decision.

The Uniform Zone Limitation

Even in an expensive multi-zone furnace, the perfectly uniform hot zone has a finite length. It is critical to match your sample size to the furnace's specified uniform zone to ensure consistent results. Simply buying a longer furnace does not guarantee a longer uniform zone without multi-zone control.

Making the Right Choice for Your Application

Selecting the right features is about matching the furnace's capabilities to your specific scientific or industrial goal.

- If your primary focus is material synthesis (e.g., CVD or nanoparticles): Prioritize atmosphere control with an integrated gas mixing system and high-vacuum capabilities.

- If your primary focus is thermal processing (e.g., annealing or sintering): Prioritize a multi-zone furnace for a large uniform hot zone and a highly programmable controller for precise ramp/soak cycles.

- If your primary focus is physical property measurement (e.g., vapor transport): Prioritize a multi-zone furnace specifically for its ability to create stable and precise temperature gradients.

By understanding these features, you can select an instrument that provides the exact degree of control your process demands.

Summary Table:

| Feature | Key Benefit | Ideal Application |

|---|---|---|

| Multi-Zone Heating | Creates precise temperature gradients or large uniform hot zones | Crystal growth, annealing, vapor transport |

| High-Vacuum Capability | Prevents contamination for sensitive processes | Semiconductor fabrication, reactive metal annealing |

| Integrated Gas Mixing | Enables stable, reproducible reactive atmospheres | Chemical Vapor Deposition (CVD), materials synthesis |

| Programmable Controllers | Automates complex thermal cycles with data logging | Ceramics firing, quality control, automated production |

| Vertical Orientation | Minimizes sample sagging and uses gravity advantages | Crucible-based experiments, specific crystal growth |

Ready to elevate your laboratory's capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization to meet your specific experimental requirements. Whether you're in semiconductor fabrication, materials research, or industrial processing, we can help you achieve unprecedented control and reproducible results. Contact us today to discuss how our solutions can benefit your projects!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents