In essence, multistage programs provide precise, phased temperature control when firing or sintering dental restorations. This granular control is not just a feature but a fundamental requirement for transforming a milled ceramic or zirconia block into a final product that is strong, dimensionally accurate, and aesthetically correct.

The core reason for multistage programs is that different physical and chemical transformations must occur at specific temperatures and for specific durations. A single, rapid heating cycle would induce thermal shock, trap impurities, and compromise the material's final integrity, leading to failed restorations.

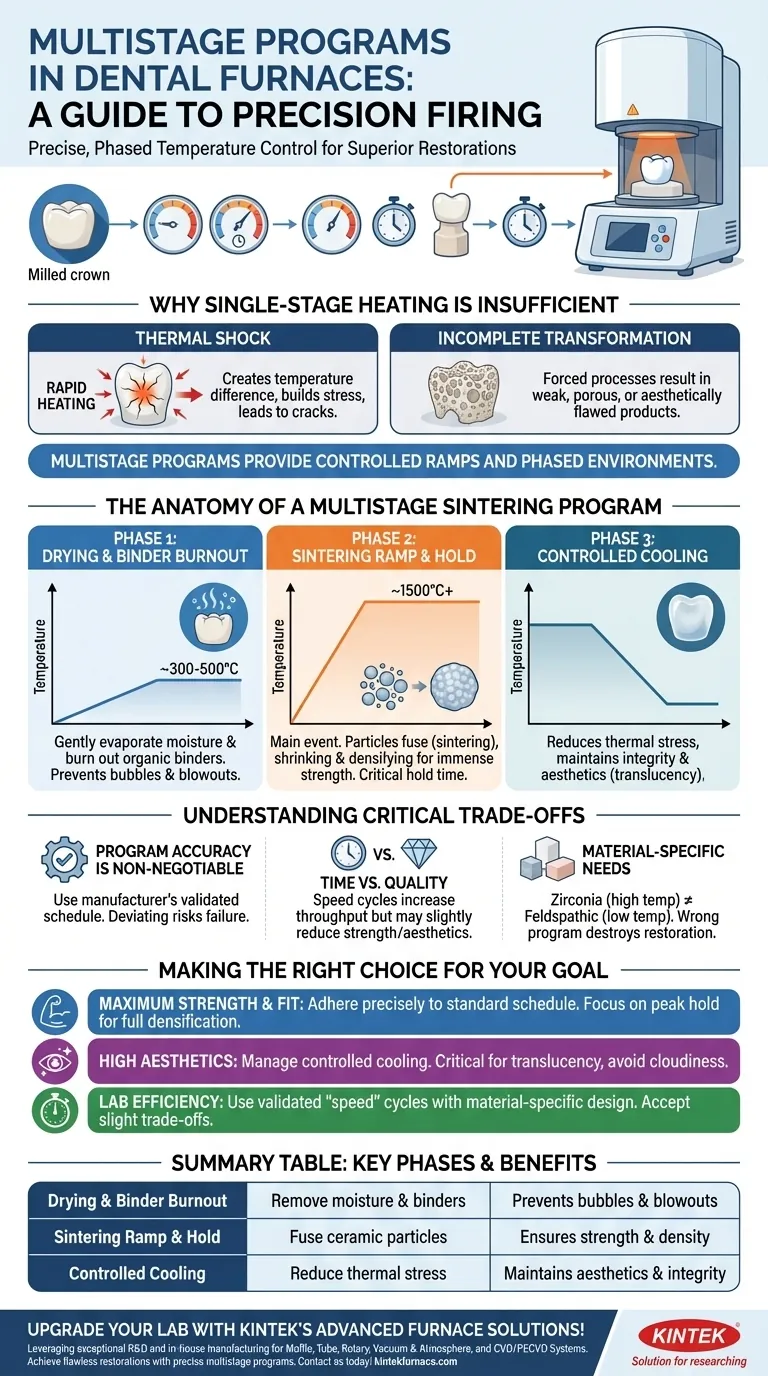

Why a Single Heating Stage Is Insufficient

To understand the value of multistage programming, one must first recognize the limitations of a simple, single-stage heating cycle. Modern dental ceramics are complex materials that cannot be rushed through the firing process.

The Problem of Thermal Shock

Heating a ceramic restoration too quickly creates a significant temperature difference between its surface and its core. This differential expansion and contraction builds internal stress, which can easily lead to cracks and fractures.

A multistage program mitigates this by using a controlled ramp rate—the speed at which the temperature increases. Slower ramps allow heat to penetrate the material evenly, preventing catastrophic thermal shock.

Material Transformation Is a Phased Process

The journey from a "green state" (milled) restoration to a final, dense ceramic involves several distinct events. Each requires its own ideal temperature environment.

Forcing these processes to happen all at once or in the wrong order results in a weak, porous, or aesthetically flawed product.

The Anatomy of a Multistage Sintering Program

A multistage program breaks the firing process down into a sequence of heating, holding, and cooling steps. While specific parameters vary dramatically by material, the fundamental phases are consistent.

Phase 1: Drying and Binder Burnout

The first stage is a low-temperature hold (typically a few hundred degrees Celsius). Its purpose is to gently evaporate any residual moisture and burn out the organic binders used during the milling process.

Skipping or rushing this stage can cause binders to vaporize too quickly, creating bubbles or "blowouts" in the ceramic structure.

Phase 2: The Sintering Ramp and Hold

This is the main event. The furnace slowly ramps up to a very high peak temperature (often over 1500°C for zirconia) and holds it for a specific period.

During this hold, the ceramic particles fuse together—a process called sintering. This shrinks the restoration to its final, dense size and gives it its immense strength. The hold time is critical for achieving full densification.

Phase 3: Controlled Cooling

The cooling cycle is just as important as the heating cycle. Cooling too rapidly reintroduces thermal stress, which can weaken the restoration or, in the case of translucent zirconia, cause cloudiness and ruin the aesthetics.

Many programs for highly aesthetic materials incorporate a slow, controlled cooling ramp to ensure maximum strength and the desired level of translucency.

Understanding the Critical Trade-offs

Using a multistage program is not automatic. The technician's understanding of the material and the program's parameters is what determines the final success.

Program Accuracy is Non-Negotiable

The single greatest cause of restoration failure related to firing is using the wrong program. Each ceramic manufacturer provides precise, validated firing schedules for their materials. Deviating from these instructions is a direct risk to the restoration's clinical viability.

Time vs. Quality

While longer cycles generally produce better results, "speed" sintering cycles have become common. These programs use faster ramp rates and shorter hold times to increase lab throughput.

However, this efficiency often comes at a cost. Speed sintering may slightly reduce the final strength or translucency of the material. It must be used judiciously and only with materials specifically validated for such cycles.

Material-Specific Needs

A program for zirconia is fundamentally different from one for lithium disilicate or feldspathic porcelain. Zirconia requires very high temperatures for sintering, while other ceramics are fired at lower temperatures to achieve a glass-like state. Using the wrong type of program will destroy the restoration.

Making the Right Choice for Your Goal

Your choice of program should be dictated entirely by the material you are using and the desired clinical outcome. Always begin with the manufacturer's recommended schedule as your baseline.

- If your primary focus is maximum strength and fit: Adhere precisely to the standard sintering schedule, paying close attention to the peak temperature hold time to ensure full densification.

- If your primary focus is high aesthetics: The controlled cooling phase is the most critical variable to manage for achieving the desired translucency and avoiding a "cloudy" appearance in materials like multilayered zirconia.

- If your primary focus is lab efficiency: Only use validated "speed" cycles for the specific materials they were designed for, and understand there may be a slight trade-off in the final physical or optical properties.

Mastering multistage programming transforms the furnace from a simple oven into a precision instrument for creating flawless and durable dental restorations.

Summary Table:

| Program Phase | Purpose | Key Benefits |

|---|---|---|

| Drying and Binder Burnout | Remove moisture and binders | Prevents bubbles and blowouts |

| Sintering Ramp and Hold | Fuse ceramic particles | Ensures strength and density |

| Controlled Cooling | Reduce thermal stress | Maintains aesthetics and integrity |

Upgrade your dental lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, with deep customization to meet your unique needs. Achieve flawless restorations with precise multistage programs—contact us today to discuss how we can enhance your lab's efficiency and quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time