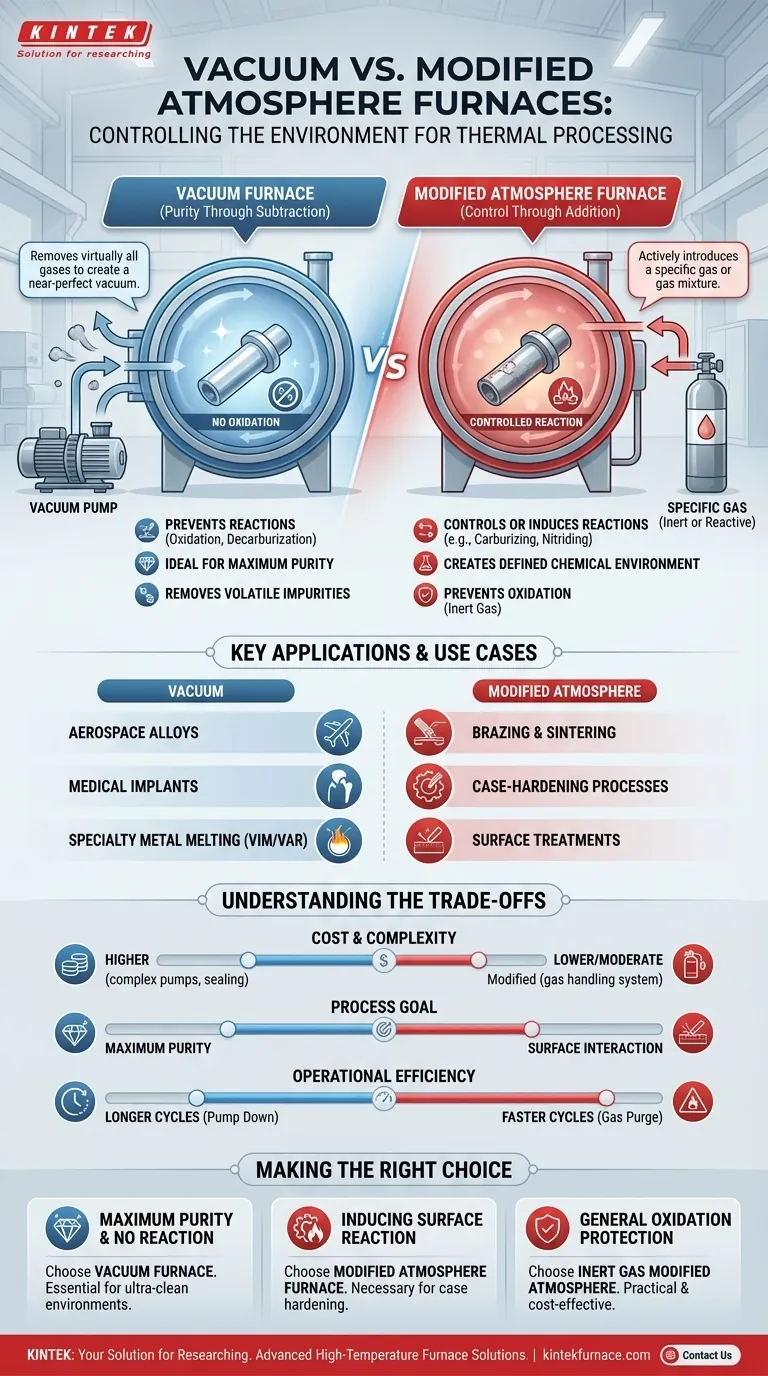

At its core, a modified atmosphere furnace controls a thermal process by actively introducing a specific gas or gas mixture, while a vacuum furnace controls it by removing virtually all gases. The former creates a precisely defined chemical environment, which can be inert or reactive, whereas the latter creates the cleanest possible environment by establishing a near-perfect vacuum to prevent any unwanted reactions.

The fundamental choice is not which furnace is superior, but whether your goal is to prevent reactions through removal (vacuum) or to control or induce reactions through addition (modified atmosphere). Understanding this distinction is the key to mastering your thermal processing.

The Fundamental Difference: Controlling the Environment

The goal of any advanced furnace is to control how a material transforms under heat. The primary difference between these two technologies lies in their strategy for controlling the atmosphere surrounding the part.

How a Vacuum Furnace Works: Purity Through Subtraction

A vacuum furnace operates on the principle of removing the environment. By pumping out air and other gases, it creates an extremely low-pressure space.

This near-vacuum prevents common high-temperature reactions like oxidation and decarburization. The removal of atmospheric gases ensures that the material being processed does not chemically interact with anything around it.

This process is ideal for achieving the highest possible purity, as it also helps pull volatile impurities and by-products out of the material itself during heating.

How a Modified Atmosphere Furnace Works: Control Through Addition

A modified atmosphere furnace, sometimes called a controlled atmosphere furnace, starts by purging the ambient air and replacing it with a specific, carefully regulated gas.

This gas can be inert, such as argon or nitrogen, to simply prevent oxidation in a more cost-effective way than a deep vacuum.

Alternatively, the gas can be reactive. For example, introducing gases for nitriding or carburizing is done to intentionally force a chemical reaction that hardens the surface of a steel part.

Key Applications and Use Cases

Your choice of furnace is dictated entirely by the desired outcome for your material.

When to Use a Vacuum Furnace

Vacuum furnaces are essential for applications where material purity and the prevention of any surface reaction are non-negotiable.

Common uses include the heat treatment of high-performance alloys for aerospace, manufacturing medical implants, and melting specialty metals using methods like Vacuum Induction Melting (VIM) or Vacuum Arc Remelting (VAR).

When to Use a Modified Atmosphere Furnace

These furnaces are used when the atmospheric environment needs to be precisely controlled, often to facilitate a specific surface treatment.

Typical applications include brazing and sintering oxidation-sensitive materials under an inert gas shield. They are also the standard for surface case-hardening processes like carburizing, nitrocarburizing, and nitriding, where the atmosphere provides the necessary elements for the reaction.

Understanding the Trade-offs

Neither technology is universally better; they are different tools for different jobs, each with distinct advantages and limitations.

Cost and Complexity

Vacuum furnaces are generally more complex and carry a higher initial cost. Achieving and maintaining a deep vacuum requires sophisticated pumps, robust chamber construction, and precise sealing, all of which contribute to higher maintenance demands.

Modified atmosphere furnaces can be simpler and more cost-effective, especially for processes that don't require extreme purity. However, they necessitate a reliable gas supply and handling system, which adds its own layer of operational complexity and safety considerations.

Process Goal: Purity vs. Surface Interaction

This is the central trade-off. If your goal is to produce a component with the absolute highest purity and an unaltered surface, a vacuum furnace is the superior choice.

If your process requires inducing a specific chemical reaction on the material's surface, a modified atmosphere furnace is not just an option—it is a necessity.

Operational Efficiency

Vacuum processes often involve longer cycle times due to the need to pump down the chamber to the target pressure before heating can begin.

Modified atmosphere furnaces can often complete cycles more quickly, as purging the chamber with gas is typically faster than drawing a deep vacuum. However, they require rigorous safety protocols, especially when using flammable gases like hydrogen.

Making the Right Choice for Your Goal

To select the correct technology, you must first define your primary objective.

- If your primary focus is achieving maximum material purity and preventing all reactions: A vacuum furnace is the only technology that can provide the ultra-clean environment you need.

- If your primary focus is inducing a specific surface reaction like case hardening: A modified atmosphere furnace is required to supply the reactive gases necessary for the process.

- If your primary focus is general heat treatment with basic oxidation protection: An inert gas modified atmosphere furnace (using nitrogen or argon) is often the most practical and cost-effective solution.

Ultimately, your success depends on choosing the furnace that provides precise control over the environment your specific material requires to achieve its intended properties.

Summary Table:

| Aspect | Vacuum Furnace | Modified Atmosphere Furnace |

|---|---|---|

| Principle | Removes gases to create a near-vacuum | Introduces specific gases (inert or reactive) |

| Primary Goal | Prevent reactions (e.g., oxidation) | Control or induce reactions (e.g., carburizing) |

| Key Applications | Aerospace alloys, medical implants, metal melting | Brazing, sintering, case-hardening processes |

| Cost & Complexity | Higher initial cost, complex vacuum systems | Lower cost, simpler but requires gas handling |

| Operational Efficiency | Longer cycle times due to pumping | Faster cycles with gas purging, safety protocols needed |

Struggling to choose the right furnace for your thermal processing needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique requirements. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you need maximum purity with vacuum furnaces or controlled reactions with modified atmosphere systems, we can help optimize your lab's efficiency and results. Contact us today to discuss your specific challenges and discover how KINTEK's expertise can benefit your operations!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity