In simple terms, high-temperature heating elements are specialized components designed to convert electrical energy into intense heat for industrial processes. They are built from advanced materials capable of withstanding extreme temperatures, often exceeding 1400°C (2550°F), and are essential in industries like metallurgy for hardening metals, ceramics for firing kilns, and chemical processing for facilitating reactions.

The crucial takeaway is that choosing a high-temperature heating element is not merely about reaching a target temperature. It is a critical engineering decision where the element's material dictates its lifespan, efficiency, and suitability for the specific chemical atmosphere of your process.

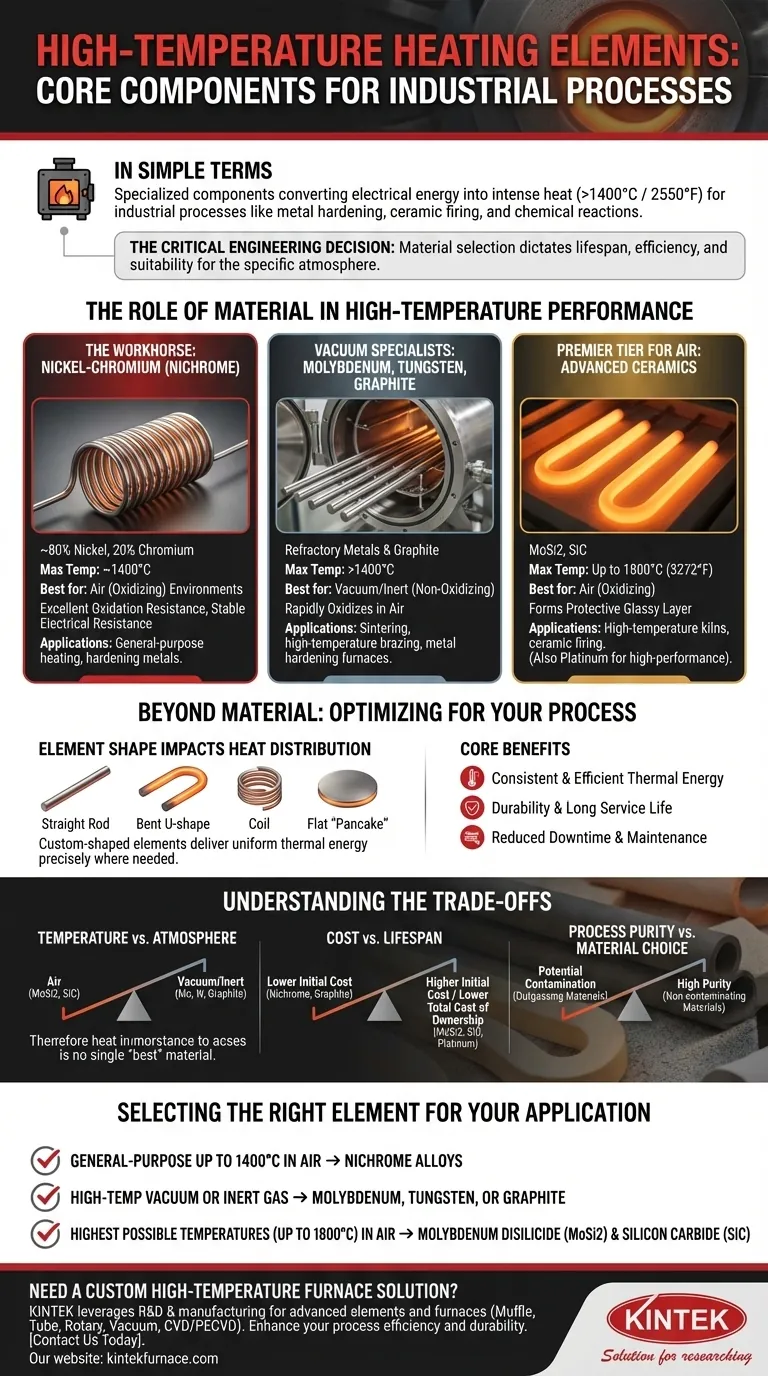

The Role of Material in High-Temperature Performance

The material is the single most important factor defining a heating element's capabilities. Different materials are suited for different temperature ranges and operating environments.

The Workhorse: Nickel-Chromium (Nichrome) Alloys

The most common material for industrial heating is nichrome, an alloy of roughly 80% nickel and 20% chromium.

Its popularity stems from a high melting point (around 1400°C), excellent resistance to oxidation at high temperatures, and relatively stable electrical resistance. This makes it a reliable and cost-effective choice for a vast range of applications.

The Vacuum Specialists: Molybdenum, Tungsten, and Graphite

For higher temperature processes conducted in a vacuum or inert gas atmosphere, refractory metals like molybdenum and tungsten are used.

These materials can operate at extremely high temperatures but will rapidly oxidize and fail if exposed to air. They are common in furnaces for processes like sintering, high-temperature brazing, and metal hardening. Graphite is another option used in similar non-oxidizing environments.

The Premier Tier for Air Atmospheres: Advanced Ceramics

To reach the highest temperatures in the presence of oxygen, manufacturers turn to advanced ceramic compounds like Molybdenum Disilicide (MoSi2) and Silicon Carbide (SiC).

These materials form a protective glassy layer on their surface that prevents oxidation, allowing them to operate reliably in furnaces at temperatures up to 1800°C (3272°F). Platinum is another exotic metal used for similar high-performance, high-temperature applications.

Beyond Material: Optimizing for Your Process

While material selection is foundational, the element's physical form and resulting benefits are also critical for process efficiency.

How Element Shape Impacts Heat Distribution

Heating elements are available in numerous forms, including straight rods, bent U-shapes, coils, and flat "pancake" heaters.

The ability to create custom-shaped elements is a significant advantage. It allows engineers to design heating systems that deliver uniform thermal energy precisely where it is needed, optimizing efficiency and improving product quality.

Core Benefits in Industrial Applications

A well-chosen heating element provides more than just heat. It delivers consistent and efficient thermal energy, ensuring predictable results and process repeatability.

Their inherent durability and long service life reduce downtime and maintenance costs, making them a cornerstone of modern manufacturing and a catalyst for innovation in developing new products and technologies.

Understanding the Trade-offs

Selecting the right element requires a clear understanding of the compromises between performance, environment, and cost.

Temperature vs. Atmosphere

There is no single "best" material for all high-temperature work. Materials like molybdenum and tungsten offer superior temperature performance but are strictly limited to vacuum or inert atmospheres.

In contrast, MoSi2 and SiC thrive in oxygen-rich environments that would destroy refractory metals, making the process atmosphere a non-negotiable factor in your selection.

Cost vs. Lifespan

Advanced materials like MoSi2, SiC, and platinum carry a significantly higher initial cost than nichrome or graphite.

However, their extended service life and higher operating capabilities can lead to a lower total cost of ownership, especially in demanding applications where frequent replacement and downtime are unacceptable.

Process Purity vs. Material Choice

The heating element itself can influence the process. Some materials may degrade or "outgas" at high temperatures, introducing contaminants into a sensitive process like semiconductor manufacturing or medical device production. This makes material purity as important as its thermal properties.

Selecting the Right Element for Your Application

Your choice must be driven by a clear understanding of your primary operational goal.

- If your primary focus is general-purpose heating up to 1400°C in air: Nichrome alloys offer the best balance of performance, reliability, and cost-effectiveness.

- If your primary focus is high-temperature vacuum or inert gas processes: Molybdenum, tungsten, or graphite are the industry standards for their exceptional heat capabilities in non-oxidizing environments.

- If your primary focus is reaching the highest possible temperatures (up to 1800°C) in an air-filled furnace: Molybdenum Disilicide (MoSi2) and Silicon Carbide (SiC) are the premier materials for the job.

Ultimately, the right heating element is the one that meets the precise demands of your process, environment, and budget.

Summary Table:

| Material | Max Temperature | Atmosphere Suitability | Common Applications |

|---|---|---|---|

| Nickel-Chromium (Nichrome) | ~1400°C | Air (Oxidizing) | General-purpose heating, hardening metals |

| Molybdenum, Tungsten, Graphite | >1400°C | Vacuum/Inert (Non-Oxidizing) | Sintering, brazing, metal hardening |

| Molybdenum Disilicide (MoSi2), Silicon Carbide (SiC) | Up to 1800°C | Air (Oxidizing) | High-temperature kilns, ceramic firing |

| Platinum | High | Air/Varies | High-performance, sensitive processes |

Need a custom high-temperature furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced heating elements and furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise performance for your unique industrial needs—contact us today to enhance your process efficiency and durability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions