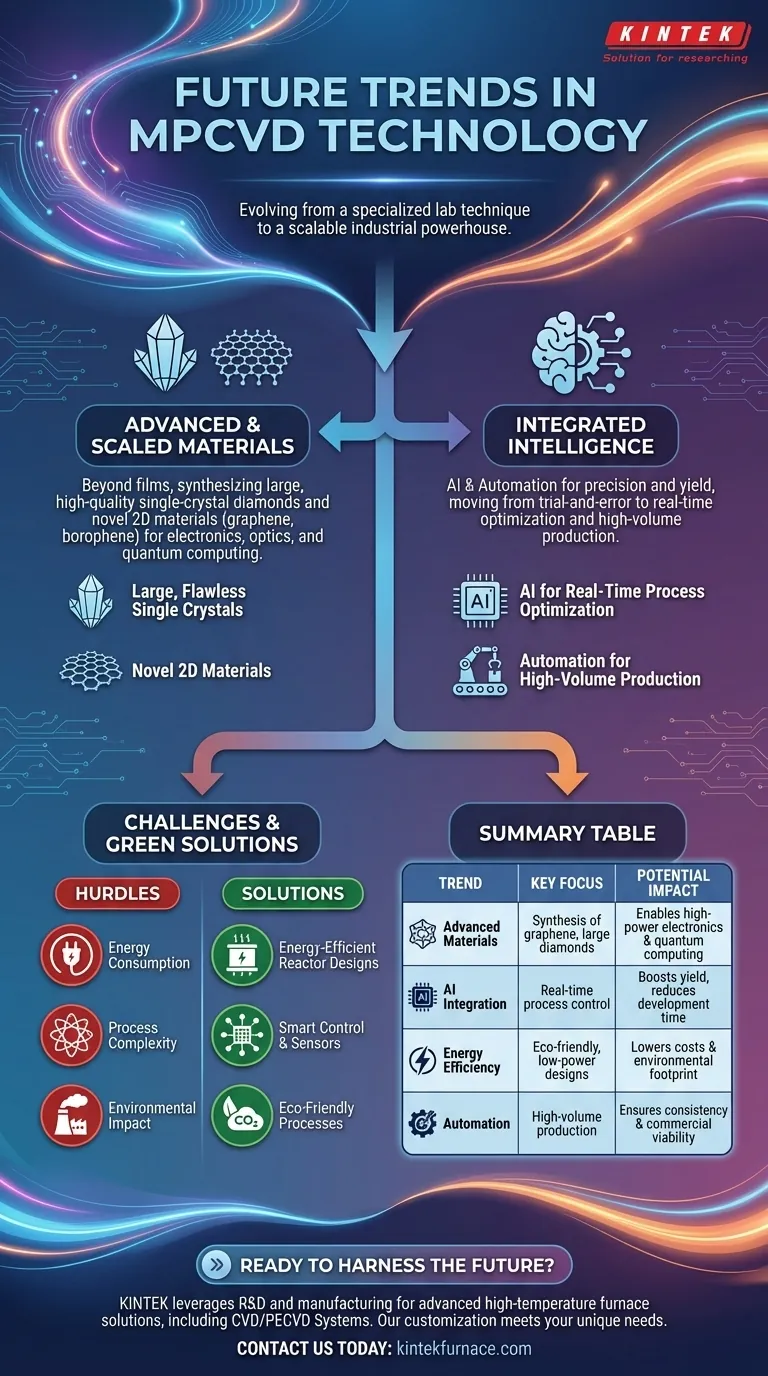

Looking forward, Microwave Plasma Chemical Vapor Deposition (MPCVD) technology is evolving beyond its current state into a more intelligent, scalable, and versatile manufacturing platform. Key future trends focus on synthesizing a wider range of advanced materials like graphene and large-crystal diamonds, integrating AI for real-time process control, developing more energy-efficient systems for mass production, and adopting more sustainable, eco-friendly processes.

The central shift in MPCVD is its maturation from a specialized laboratory technique into a cornerstone of industrial manufacturing. The future is defined by making exotic materials like flawless, large-scale diamonds and 2D nanomaterials not just possible, but commercially viable and produced with automated precision.

The Push Towards Advanced and Scaled Materials

The core driver of MPCVD innovation is the demand for next-generation materials that existing methods cannot produce at scale or with sufficient quality. The technology is expanding its repertoire to meet this need.

The Quest for Large, Flawless Single Crystals

Initially known for producing polycrystalline diamond films, the frontier has moved to growing large, high-quality single-crystal diamonds.

These large-area crystals are critical for demanding applications in high-power electronics, specialized optics, and high-pressure research, where purity and structural integrity are paramount. MPCVD offers a path to synthesizing these materials at a potentially lower cost than traditional high-pressure, high-temperature (HPHT) methods.

Beyond Diamond: Synthesizing Novel 2D Materials

The precise control offered by MPCVD is being adapted for the deposition of other advanced nanomaterials.

This includes 2D materials like graphene, carbon nanotubes, and even more exotic substances like borophene. These materials are foundational for future technologies, including quantum computing and next-generation semiconductors, making MPCVD a critical enabling tool for their development and eventual production.

Integrating Intelligence for Precision and Yield

To move from the lab to the factory floor, MPCVD systems must become more predictable, repeatable, and efficient. The integration of data science and automation is the key to achieving this leap.

AI for Real-Time Process Optimization

Traditionally, finding the right "recipe" for a specific material has been a time-consuming, trial-and-error process.

The future involves integrating AI and machine learning algorithms directly into the control loop. These systems can monitor plasma conditions and growth in real time, making micro-adjustments to gas flow, pressure, and power to optimize for quality and yield, dramatically reducing development cycles.

Automation for High-Volume Production

As processes are perfected, the focus shifts to repeatability and scale. Fully automated MPCVD systems will manage everything from substrate loading to final quality control.

This reduces the potential for human error, ensures consistency across batches, and enables the mass production necessary to make these advanced materials economically viable for widespread use.

Understanding the Trade-offs and Challenges

While the future is promising, the path to widespread industrialization involves overcoming significant technical and economic hurdles. Acknowledging these challenges is crucial for realistic planning.

The Energy Consumption Challenge

MPCVD is an energy-intensive process, requiring significant microwave power to generate and sustain a stable plasma. A major area of ongoing research is the development of more energy-efficient reactor designs and plasma generation techniques to reduce the operational cost and environmental footprint of large-scale production.

The Complexity of Process Control

The physics and chemistry inside an MPCVD reactor are incredibly complex. While AI provides a powerful tool for optimization, it relies on accurate sensor data and a deep understanding of the underlying processes. Managing plasma stability, uniformity over large areas, and precursor chemistry remains a significant engineering challenge.

The Drive for Greener Chemistry

As MPCVD becomes a high-volume manufacturing process, its environmental impact comes under greater scrutiny. Future trends include a focus on eco-friendly processes that minimize the use of hazardous precursor gases and reduce or neutralize toxic by-products, ensuring the technology's long-term sustainability.

Making the Right Choice for Your Goal

The evolution of MPCVD creates distinct opportunities depending on your field. Aligning your efforts with these trends is key to staying at the forefront of innovation.

- If your primary focus is materials research: Concentrate on exploring novel precursors and plasma conditions to synthesize emerging materials like borophene or unique diamond nitrogen-vacancy (NV) centers for quantum applications.

- If your primary focus is industrial manufacturing: Prioritize the integration of AI-driven control systems and the development of energy-efficient reactor designs to improve yield, lower costs, and enable scalable production.

- If your primary focus is device engineering: Begin designing and prototyping next-generation devices that leverage the unique properties of large-area, high-quality diamonds and graphene films that will soon become more accessible.

Ultimately, MPCVD is becoming the critical bridge between the theoretical promise of advanced materials and their real-world application.

Summary Table:

| Trend | Key Focus | Potential Impact |

|---|---|---|

| Advanced Materials | Synthesis of graphene, large diamonds, and 2D materials | Enables high-power electronics and quantum computing |

| AI Integration | Real-time process control and optimization | Boosts yield, reduces development time |

| Energy Efficiency | Eco-friendly, low-power reactor designs | Lowers costs and environmental footprint |

| Automation | High-volume production with minimal human error | Ensures consistency and commercial viability |

Ready to harness the future of MPCVD for your lab or production line? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental and industrial needs. Contact us today to discuss how our expertise can drive your innovations forward!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What future trends are expected in the development of CVD tube furnaces? Discover Smarter, More Versatile Systems

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab