At its core, a dental porcelain furnace is a specialized high-temperature oven used to fire ceramic materials, transforming them into strong, aesthetic, and perfectly fitting dental restorations. These furnaces are essential tools in a dental laboratory for fabricating crowns, bridges, veneers, inlays, and onlays. The process involves precisely controlled heating cycles that harden the porcelain, achieve the desired color and translucency, and apply a final, life-like glaze.

The true value of a dental furnace lies not merely in its ability to generate heat, but in its capacity for precision control. It meticulously manages temperature, time, and vacuum pressure to ensure every dental restoration achieves the exact strength, fit, and aesthetic properties required by the clinician and patient.

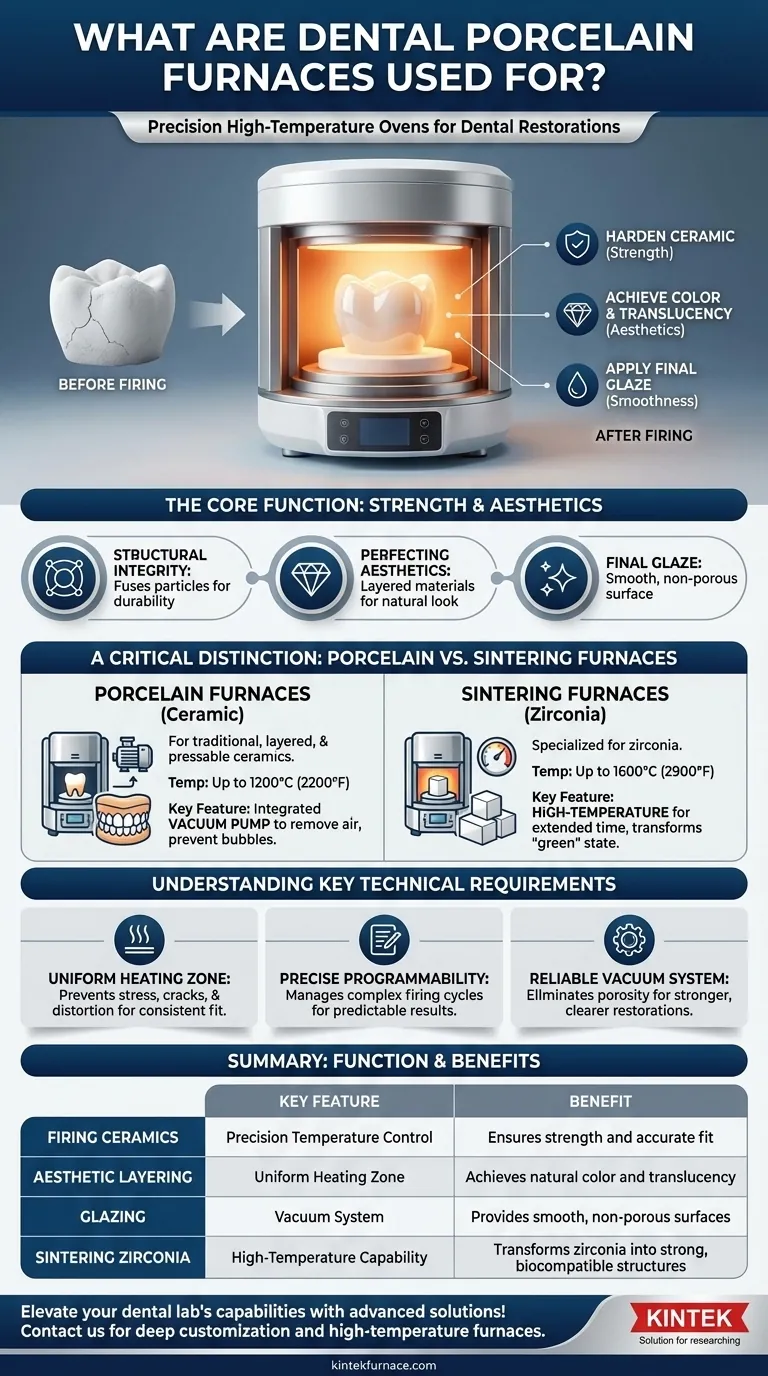

The Core Function: Creating Strength and Aesthetics

A dental furnace executes a series of programmed heating cycles to process ceramic materials. This firing process is fundamental to the final quality of any ceramic-based restoration.

Achieving Structural Integrity

The primary purpose of firing is to harden the ceramic material, transforming it from a fragile, chalky state into a dense, durable final product. The furnace fuses the individual ceramic particles together, a process that gives the restoration its strength and ability to withstand the forces of chewing.

Perfecting the Aesthetics

Beyond strength, the furnace is critical for achieving a natural look. Technicians build up restorations in layers (such as opaque, dentine, and enamel materials), with each layer requiring a specific firing cycle to mature its color and translucency. This layering mimics the structure of a natural tooth.

The Final Glaze

The last step is often a stain and glaze firing. This cycle creates a smooth, non-porous, and high-shine surface on the restoration. This glaze not only enhances the aesthetic but also prevents plaque accumulation and wear on opposing teeth.

A Critical Distinction: Porcelain vs. Sintering Furnaces

While often discussed together, it's crucial to distinguish between two primary types of dental furnaces, as they serve different purposes for different materials.

Porcelain (or Ceramic) Furnaces

These are the most common type, used for firing traditional feldspathic porcelains, layered ceramics, and pressable ceramic materials. They typically operate at temperatures up to 1200°C (2200°F). A key feature is an integrated vacuum pump, which removes air during firing to prevent bubbles and create dense, translucent restorations.

Sintering Furnaces

Sintering furnaces are specialized for processing zirconia. After a zirconia crown or bridge is milled from a block, it exists in a soft, "green" state. The sintering furnace takes this framework to much higher temperatures—often up to 1600°C (2900°F)—for an extended period. This process, called sintering, shrinks the material and transforms it into an incredibly strong and biocompatible final structure.

Understanding the Key Technical Requirements

The effectiveness of a furnace is not accidental; it depends on specific technical features that directly impact the quality of the final product. Understanding these is key to avoiding costly remakes.

Uniform Heating Zone

Inconsistent temperature within the firing chamber is a primary cause of restoration failure. A uniform heating zone ensures the entire restoration heats and cools at the same rate, preventing internal stress, cracks, and distortion that would compromise the fit.

Precise Programmability

Modern dental labs use a wide variety of ceramic materials, each with a unique, manufacturer-specified firing schedule. A furnace must have a programmable controller that allows technicians to precisely manage every stage of the heating and cooling cycle for consistent, predictable results.

Reliable Vacuum System

For porcelain restorations, the vacuum system is non-negotiable. By removing air from the chamber during the firing cycle, it eliminates porosity in the ceramic. This results in a stronger, clearer, and more aesthetically pleasing restoration.

Making the Right Choice for Your Goal

Selecting the right furnace technology is a critical decision for any dental laboratory, as it directly influences workflow efficiency and the quality of the final product.

- If your primary focus is aesthetic layered or pressable restorations: A versatile porcelain furnace with precise temperature control and a reliable vacuum system is your essential tool.

- If your primary focus is high-strength zirconia frameworks: A dedicated high-temperature sintering furnace is non-negotiable to achieve the required material density and strength.

- If you run a full-service digital lab: You will almost certainly require both types of furnaces to effectively handle the complete spectrum of modern restorative materials.

Ultimately, investing in the correct furnace technology is a direct investment in the quality, consistency, and success of your final restorations.

Summary Table:

| Function | Key Feature | Benefit |

|---|---|---|

| Firing Ceramics | Precision Temperature Control | Ensures strength and accurate fit of restorations |

| Aesthetic Layering | Uniform Heating Zone | Achieves natural color and translucency in teeth |

| Glazing | Vacuum System | Provides smooth, non-porous surfaces for durability |

| Sintering Zirconia | High-Temperature Capability | Transforms zirconia into strong, biocompatible structures |

Elevate your dental lab's capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs, whether you're working with porcelain or zirconia. Contact us today to discuss how our high-temperature furnaces can enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations