Based on direct customer feedback, the dental zirconia sintering furnace exhibits strong long-term performance, characterized by sustained reliability and consistent operational output. Users report that the furnace continues to function "like new" more than a year into service, dependably maintaining precise temperature control and producing high-quality results without degradation over time.

The core value of this furnace extends beyond simple durability. Its long-term performance is defined by a combination of mechanical reliability, operational efficiency, and consistent, high-quality clinical output, making it a stable foundation for a productive dental lab workflow.

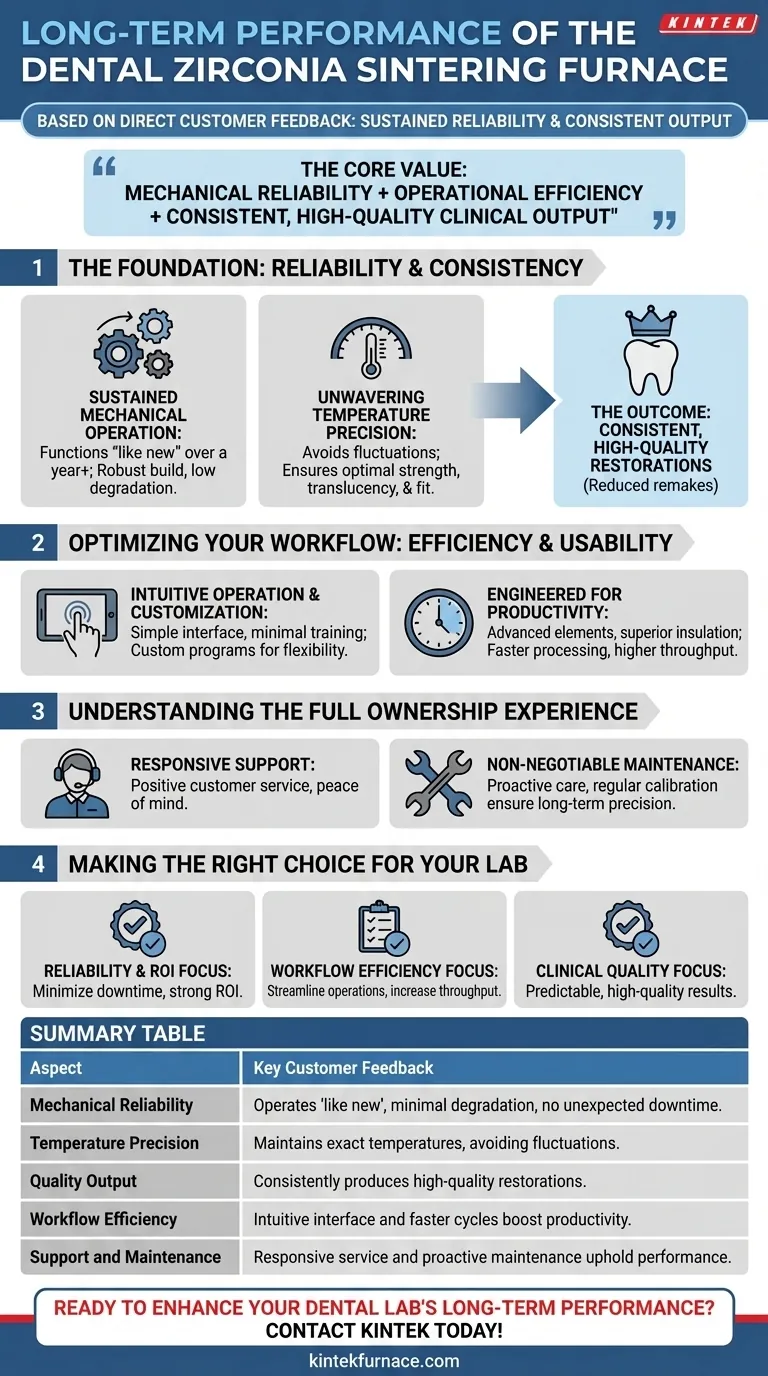

The Foundation of Long-Term Performance: Reliability and Consistency

The primary concern for any significant lab equipment investment is whether it will perform reliably day after day. The feedback for this furnace centers on its ability to deliver predictable results without fail.

Sustained Mechanical Operation

Customers specifically note the furnace's durability. One user highlighted that after more than a year of consistent use, their unit continues to operate with the same performance as it did on day one.

This indicates a robust build quality and a low rate of mechanical degradation, which is critical for avoiding unexpected downtime and costly repairs in a busy lab environment.

Unwavering Temperature Precision

A key aspect of its long-term performance is the ability to maintain precise sintering temperatures. Users confirm the furnace avoids temperature fluctuations, a common point of failure in lesser equipment.

This precision is the cornerstone of successful zirconia processing, ensuring the material achieves optimal strength, translucency, and marginal fit.

The Outcome: Consistent, High-Quality Restorations

The combination of mechanical reliability and temperature control leads to one crucial business outcome: consistently high-quality restorations.

By precisely managing temperature and sintering time, the furnace ensures that every crown, bridge, or framework meets exacting quality standards, reducing the need for costly remakes.

Optimizing Your Workflow: Efficiency and Usability

Long-term performance isn't just about whether the machine turns on; it's also about how it integrates into and enhances your daily workflow over many years.

Intuitive Operation and Customization

The furnace features an intuitive touchscreen interface that customers find simple to navigate, requiring minimal staff training.

Setting up sintering cycles is straightforward, and the ability to create custom programs for different zirconia materials provides long-term flexibility as new products enter the market.

Engineered for Productivity

The furnace's efficiency is attributed to its core design, which includes advanced heating elements and superior insulation.

These components work together to enable precise temperature control while reducing overall processing times. This directly translates to increased productivity and higher case throughput for the lab.

Understanding the Full Ownership Experience

Excellent long-term performance is a function of both the machine's engineering and the support system surrounding it. A holistic view is necessary when evaluating its true value.

The Role of Responsive Support

While the machine itself is reliable, customers also report positive experiences with the manufacturer's customer service.

Having access to responsive and helpful support for questions or troubleshooting is a critical component of the long-term ownership experience, providing peace of mind.

The Non-Negotiable of Maintenance

No piece of high-performance equipment operates in a vacuum. Achieving the reported levels of long-term reliability is contingent on following the manufacturer's recommended maintenance schedule.

Proactive care of heating elements and regular calibration are key to ensuring the furnace delivers precise and consistent results for its entire operational lifespan.

Making the Right Choice for Your Lab

To determine if this furnace aligns with your goals, consider your primary operational drivers.

- If your primary focus is reliability and ROI: The furnace's durable build and consistent output minimize costly downtime and remakes, supporting a strong return on investment.

- If your primary focus is workflow efficiency: The intuitive interface and faster processing cycles are engineered to streamline daily operations and increase your lab's overall throughput.

- If your primary focus is clinical quality: The unit’s precise temperature control is designed to deliver predictable, high-quality sintering results, ensuring every restoration meets your highest standards.

Ultimately, this furnace is assessed not just on its durability, but on its capacity to serve as a reliable engine for a productive and quality-focused dental laboratory.

Summary Table:

| Aspect | Key Customer Feedback |

|---|---|

| Mechanical Reliability | Operates 'like new' after over a year, with minimal degradation and no unexpected downtime. |

| Temperature Precision | Maintains exact sintering temperatures, avoiding fluctuations for optimal zirconia strength and fit. |

| Quality Output | Consistently produces high-quality restorations, reducing remakes and ensuring clinical standards. |

| Workflow Efficiency | Intuitive interface and faster cycles boost productivity and case throughput in daily operations. |

| Support and Maintenance | Responsive customer service and proactive maintenance uphold long-term performance and peace of mind. |

Ready to enhance your dental lab's long-term performance? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Experience reliable, efficient, and high-quality results—contact us today to discuss how our furnaces can support your workflow and drive success!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency