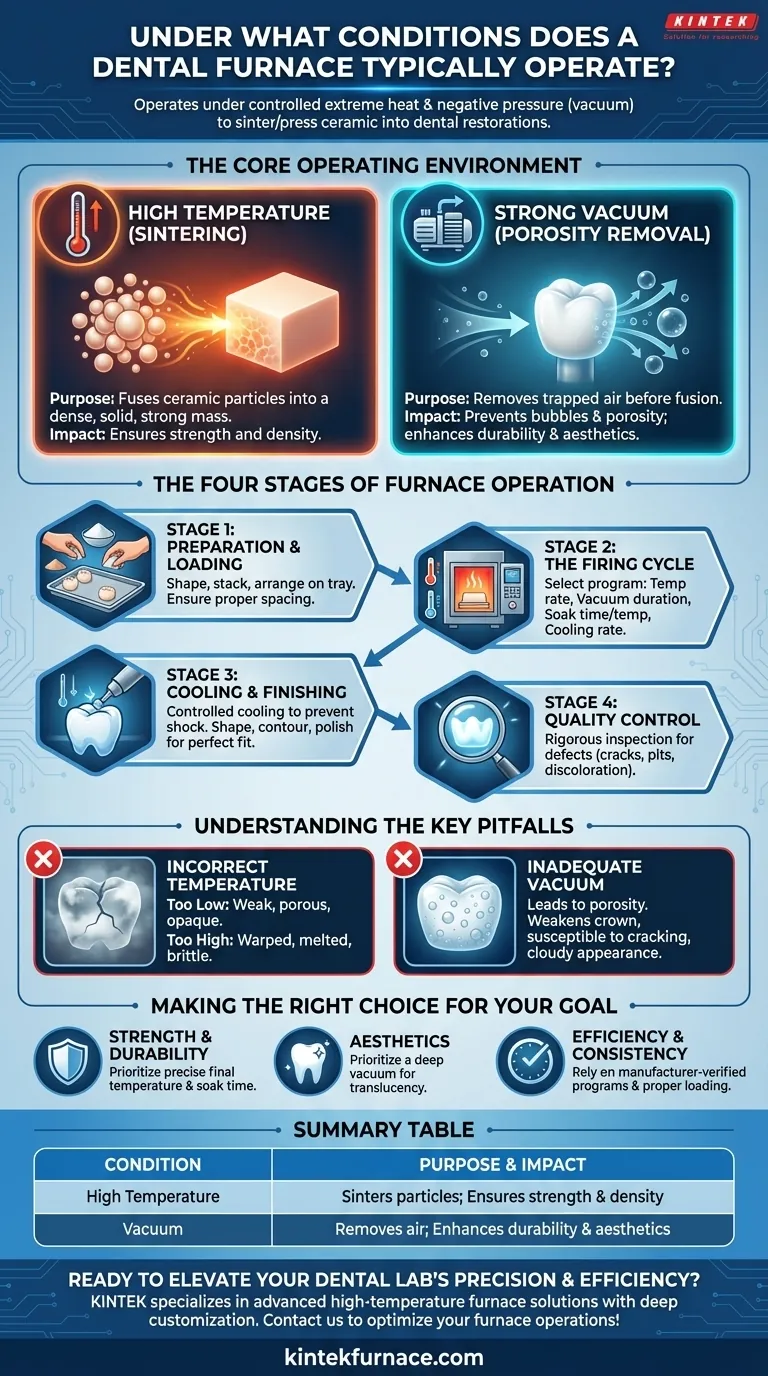

A dental furnace operates under a highly controlled environment of extreme heat and negative pressure, or vacuum. These two conditions—accurate temperature and a strong vacuum—are the essential parameters required to properly sinter or press ceramic materials into durable and aesthetically pleasing dental restorations like crowns or veneers.

The success of a dental restoration is determined not by a single setting, but by a precise, multi-stage process. The core operating conditions of high heat and vacuum are critical for eliminating material porosity and ensuring the final product meets exacting functional and aesthetic standards.

The Core Operating Environment

To produce a successful restoration, the furnace must create an ideal environment for the ceramic material. This environment is defined by two primary conditions.

The Purpose of High Temperature

The fundamental role of the furnace is to heat a ceramic block or powder to a specific, extremely high temperature.

This process, known as sintering, causes the individual ceramic particles to fuse together, creating a dense, solid, and strong mass.

The exact temperature profile—including the rate of heating, the final "soak" temperature, and the cooling rate—is dictated by the specific type of ceramic being used.

The Critical Role of Vacuum

Dental furnaces almost always operate under a vacuum. Pulling air out of the firing chamber serves a crucial purpose.

It removes trapped air from between the ceramic particles before they fuse together. This prevents the formation of air bubbles and porosity within the final restoration.

A restoration free of voids is significantly stronger, more fracture-resistant, and has a smoother, more translucent finish that better mimics a natural tooth.

The Four Stages of Furnace Operation

Achieving the right conditions is part of a meticulous workflow. The operation is not a simple "on/off" task but a carefully managed process.

Stage 1: Preparation and Loading

Before the cycle begins, the technician prepares the raw ceramic material, which may involve shaping or stacking powders.

The pieces are then carefully arranged on a firing tray inside the furnace chamber. Proper spacing is essential to ensure even heat distribution and prevent restorations from touching during the cycle.

Stage 2: The Firing Cycle

This is the heart of the operation. The technician selects a pre-programmed or custom firing cycle based on the manufacturer's instructions for the specific ceramic.

This program controls the exact rate of temperature increase, the duration of the vacuum, the final soak temperature and time, and the rate of cooling.

Stage 3: Cooling and Finishing

Once the firing cycle is complete, the furnace begins a controlled cooling phase to prevent thermal shock, which could crack the restoration.

After the restoration has cooled completely, it is removed from the furnace. It is then shaped, contoured, and polished using specialized equipment to ensure a perfect fit and natural appearance.

Stage 4: Quality Control

The final step is a rigorous inspection. The finished restoration is checked for any defects, such as cracks, pits, or discoloration.

This ensures the final product meets the high functional and aesthetic standards required for patient use.

Understanding the Key Pitfalls

Precision is non-negotiable in this process. Small deviations from the ideal conditions can lead to a failed restoration.

The Risk of Incorrect Temperature

If the temperature is too low or the soak time is too short, the ceramic will not fully sinter. This results in a weak, porous, and opaque restoration that is prone to fracture.

Conversely, if the temperature is too high, the ceramic can warp, melt, or become glassy and brittle, ruining its fit and appearance.

The Consequence of Inadequate Vacuum

Failure to achieve and hold a proper vacuum is a common cause of failure. It directly leads to porosity in the final restoration.

These internal voids act as stress points, dramatically weakening the crown or bridge and making it susceptible to cracking under normal chewing forces. Aesthetically, they can also cause a cloudy or discolored appearance.

Making the Right Choice for Your Goal

Your procedural focus will determine which operating condition you prioritize monitoring.

- If your primary focus is strength and durability: Ensure the furnace is calibrated to reach the precise final temperature and hold it for the required soak time for complete sintering.

- If your primary focus is aesthetics: Confirm the vacuum pump is functioning correctly to achieve a deep vacuum, which is critical for eliminating bubbles and achieving ideal translucency.

- If your primary focus is efficiency and consistency: Rely on manufacturer-verified, material-specific programs and ensure proper loading techniques to prevent errors and minimize rework.

Mastering the relationship between temperature, vacuum, and material is the key to producing consistently flawless dental restorations.

Summary Table:

| Condition | Purpose | Impact on Restoration |

|---|---|---|

| High Temperature | Sinters ceramic particles | Ensures strength and density |

| Vacuum | Removes air to prevent porosity | Enhances durability and aesthetics |

Ready to elevate your dental lab's precision and efficiency? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental applications. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs—whether you're sintering ceramics for crowns or veneers. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, designed to deliver consistent, flawless results. Contact us today to discuss how KINTEK can optimize your furnace operations and boost your restoration quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab