In environmental science, a muffle furnace is used to prepare samples for analysis through a process called ashing. This high-temperature heating, typically above 500°C, is designed to efficiently burn away organic substances from samples like soil or dried water residue. By removing this organic interference, the purity of the remaining inorganic material is significantly increased, allowing for far more accurate measurement of pollutants like heavy metals.

The core purpose of using a muffle furnace in environmental analysis is not simply to heat a sample, but to purify it. By controllably combusting organic matter, the furnace isolates the inorganic components, which is a critical step for obtaining accurate and reliable data on non-volatile pollutants.

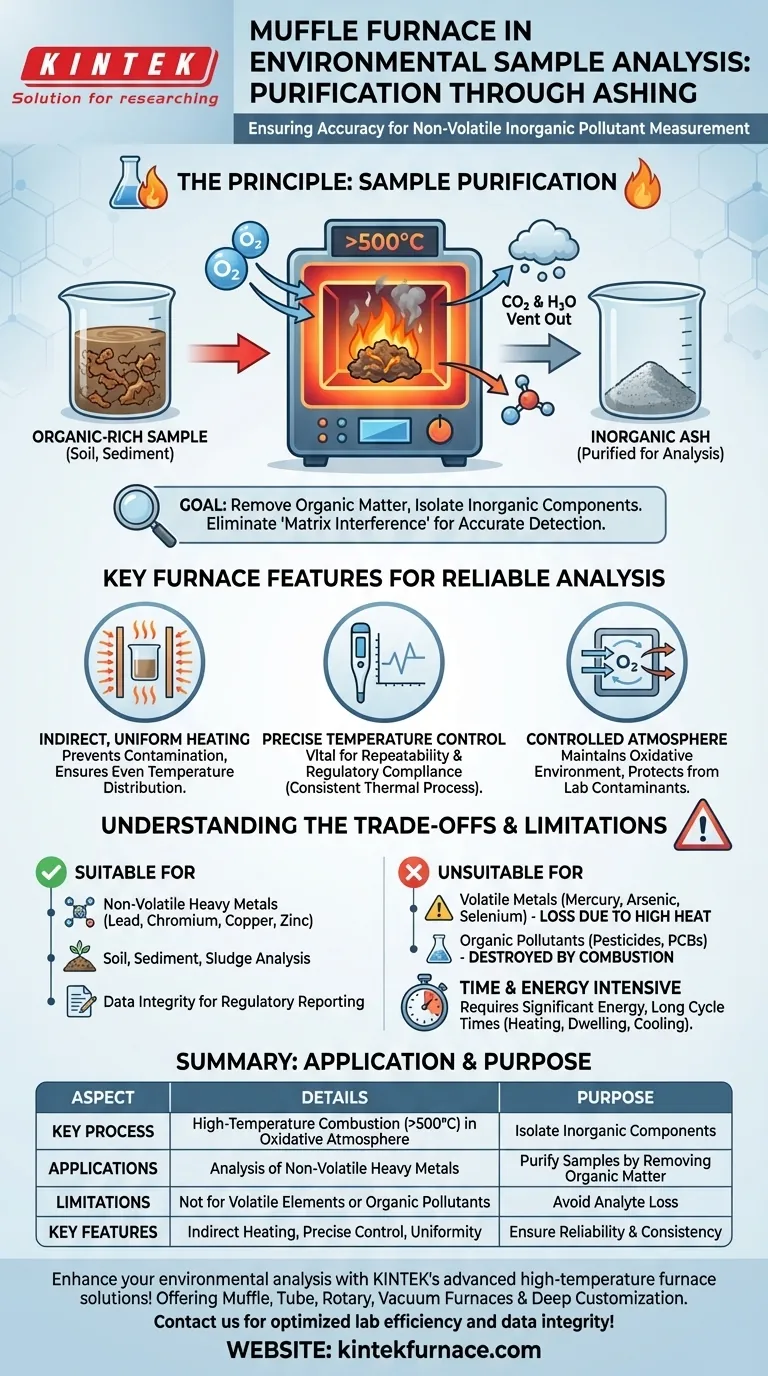

The Principle: Sample Purification Through Ashing

The fundamental goal is to create a "clean" sample where the target analytes can be measured without interference. The muffle furnace achieves this through controlled, high-temperature combustion.

What is Ashing?

Ashing is the process of reducing a substance to its non-combustible inorganic components, or ash. In a muffle furnace, this is done by heating the sample in the presence of air (an oxidative atmosphere).

The high heat and oxygen supply cause the organic carbon-based compounds to combust and turn into carbon dioxide and water, which vent out of the furnace.

Why Remove Organic Matter?

Environmental samples like soil, sediment, and sludge are rich in organic material. This material can interfere with the analytical instruments used to detect inorganic pollutants.

By burning it away, you eliminate this "matrix interference," ensuring that the instrument is measuring only the target pollutant, such as lead or cadmium, and not being skewed by the presence of complex organic molecules.

The Critical Temperature: Above 500°C

A temperature threshold of 500°C or higher is required to ensure the complete and efficient combustion of most organic compounds found in environmental samples.

Operating below this temperature can lead to incomplete ashing, leaving behind residual carbon that can compromise the accuracy of the final analysis.

Key Furnace Features for Reliable Analysis

A muffle furnace is not just a simple oven. Its specific design features are what make it indispensable for high-quality sample preparation.

Indirect, Uniform Heating

The "muffle" is a refractory ceramic chamber that separates the heating elements from the sample. This means the sample is heated by radiation and convection, not by direct flame contact.

This indirect heating prevents contamination from combustion byproducts of a fuel source and ensures the temperature is distributed evenly throughout the chamber, preventing localized overheating or cool spots.

Precise Temperature Control

Modern muffle furnaces offer exceptional temperature control. This precision is vital for repeatability.

Protocols for environmental analysis demand that all samples be treated identically. Precise control ensures that every sample batch undergoes the exact same thermal process, leading to consistent and legally defensible data.

Controlled Atmosphere

While ashing requires an oxidative atmosphere (air), the furnace's sealed chamber allows for this to be managed. It ensures a consistent supply of oxygen for combustion while protecting the sample from airborne contaminants in the lab.

Understanding the Trade-offs

While powerful, the ashing technique is not a universal solution. Understanding its limitations is critical for proper application.

Analyte Volatility

The primary limitation is analyte loss due to volatility. The high temperatures used for ashing will cause volatile or semi-volatile elements, such as mercury, arsenic, and selenium, to turn into a gas and be lost.

Therefore, this method is fundamentally unsuitable for analyzing those specific pollutants. Other methods, like acid digestion at lower temperatures, must be used.

Energy and Time Consumption

Reaching and maintaining temperatures over 500°C requires significant electrical energy. Furthermore, the complete cycle of heating, holding at temperature (dwelling), and safely cooling down can take several hours.

This makes the process a potential bottleneck in labs with high sample throughput and adds to operational costs.

Making the Right Choice for Your Analysis

The decision to use a muffle furnace hinges entirely on the nature of the pollutant you intend to measure.

- If your primary focus is non-volatile heavy metals (e.g., lead, chromium, copper, zinc) in soil or sediment: Ashing in a muffle furnace is a standard and highly effective method for removing organic interference before analysis.

- If your primary focus is volatile metals (e.g., mercury) or any organic pollutants (e.g., pesticides, PCBs): This method is entirely inappropriate, as the high heat will destroy or drive off your target analytes.

- If your primary focus is data integrity for regulatory reporting: Using a calibrated muffle furnace with proven temperature uniformity is essential for producing the consistent, repeatable results required for environmental compliance.

Ultimately, mastering this technique is a foundational skill for any analyst seeking accurate data on inorganic contaminants in complex environmental samples.

Summary Table:

| Aspect | Details |

|---|---|

| Purpose | Purify samples by removing organic matter via ashing for accurate inorganic pollutant analysis. |

| Key Process | High-temperature combustion (>500°C) in an oxidative atmosphere to isolate inorganic components. |

| Applications | Analysis of non-volatile heavy metals (e.g., lead, chromium) in soil, sediment, and sludge. |

| Limitations | Not suitable for volatile elements (e.g., mercury) or organic pollutants due to analyte loss. |

| Key Features | Indirect heating, precise temperature control, uniform heating, and controlled atmosphere for reliability. |

Enhance your environmental analysis with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior sample purification and accurate results. Contact us today to discuss how our solutions can optimize your lab's efficiency and data integrity!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation