Proper maintenance of a dental ceramic furnace is a systematic process that goes far beyond simple cleaning. It requires regular calibration of temperature controls, thorough cleaning of the firing chamber, and diligent inspection of critical components like heating elements and thermocouples. Adhering to the manufacturer's specific guidelines is paramount to ensuring both the longevity of the equipment and the quality of the final restorations.

The central purpose of furnace maintenance is to guarantee temperature accuracy and environmental purity during the firing cycle. Any deviation in temperature or contamination in the chamber directly compromises the physical properties and aesthetics of the ceramic, leading to failed restorations and wasted resources.

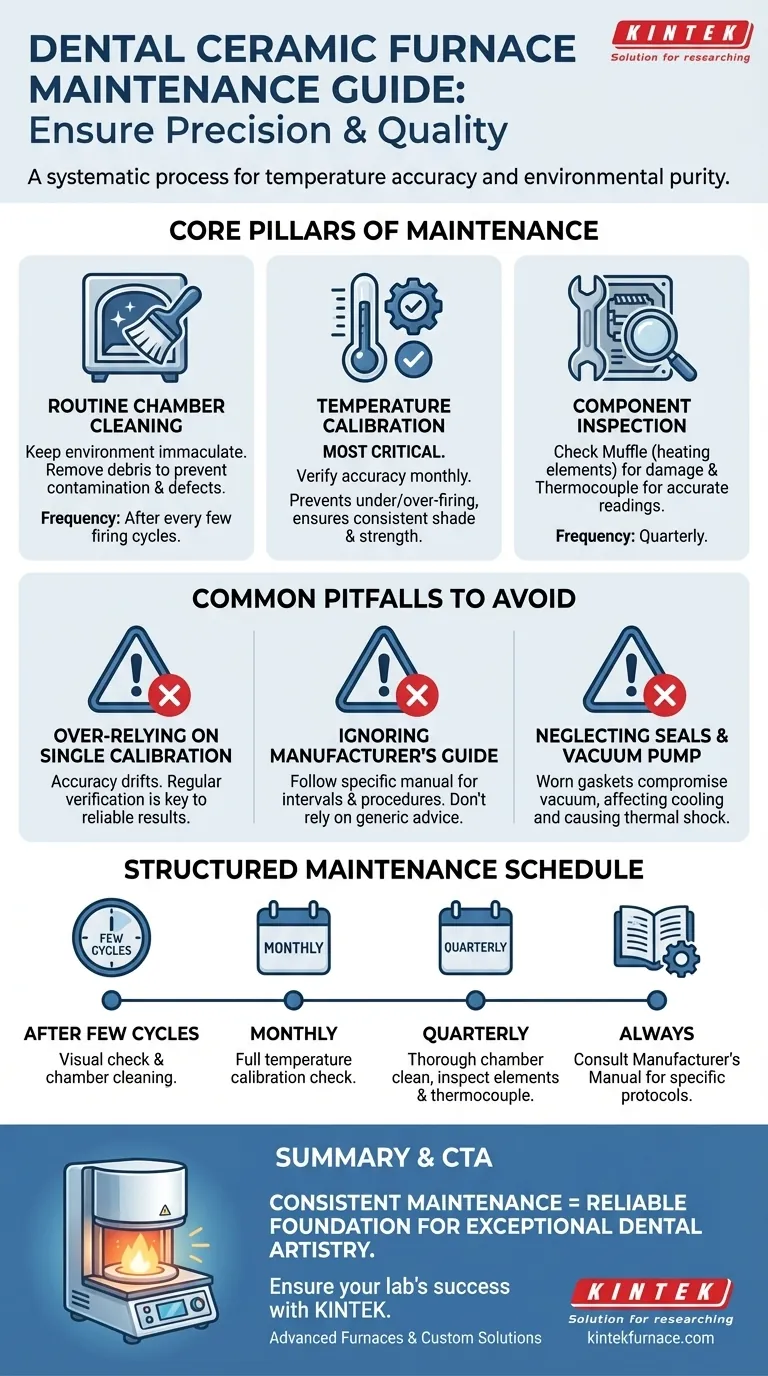

The Core Pillars of Furnace Maintenance

To achieve consistent, high-quality results, your maintenance routine must focus on the three factors that directly influence the firing process: the chamber environment, temperature accuracy, and the health of heat-generating components.

Routine Chamber Cleaning

The firing chamber must be an immaculate environment. Debris or contaminants left over from previous cycles can vaporize at high temperatures and embed into new restorations, causing discoloration and defects.

A clean chamber ensures that the only material being fired is the ceramic itself, leading to predictable and aesthetically pure results. This should be a frequent task, performed after every few firing cycles.

Temperature Calibration and Verification

This is the single most critical maintenance task. A dental furnace's primary function is to execute a precise temperature profile, and you cannot trust the digital display blindly.

The furnace's internal thermometer, the thermocouple, can drift over time. Regular calibration using an external, verified thermometer ensures that when the program calls for 960°C, the chamber is actually at 960°C. Without this, you risk under- or over-firing the ceramic, which ruins its crystalline structure, strength, and shade.

Inspection of Critical Components

Several components work together to achieve the correct firing cycle. Their failure can be gradual, and only visual inspection will reveal a problem before it ruins a batch of work.

Heating Elements The heating elements (or muffle) generate the heat. Over time, they can degrade, crack, or sag. This leads to uneven heating within the chamber, causing one side of a restoration to be fired differently than the other. Look for signs of discoloration, flaking, or physical damage.

The Thermocouple The thermocouple is the sensor that reads the temperature inside the chamber and reports it to the controller. A degraded or contaminated thermocouple will provide inaccurate readings. The furnace may believe it's at the correct temperature when it is not, making accurate firing impossible even with perfect heating elements.

Common Pitfalls and Oversights

Even labs with a maintenance schedule can fall into traps that compromise their output. Avoiding these common oversights is key to truly reliable furnace operation.

Over-relying on a Single Calibration

Temperature calibration is not a "set it and forget it" task. The accuracy of a furnace can drift due to aging components and heavy use. A furnace calibrated in January may be significantly off by June. Verification should be a regular, scheduled event.

Ignoring the Manufacturer's Guide

The reference materials provided by your furnace's manufacturer are not suggestions; they are your primary operational directive. They contain specific maintenance intervals, part numbers, and calibration procedures tailored to that machine's unique design and materials. Generic advice is helpful, but the manufacturer's guide is definitive.

Neglecting Seals and the Vacuum Pump

Many firing cycles rely on a vacuum to remove oxygen and prevent bubbling. A worn door gasket or a failing vacuum pump seal can cause a loss of vacuum during the cycle. This not only affects the ceramic but can also impact the cooling rate, potentially causing thermal shock and cracking in the final restoration.

Structuring Your Maintenance Schedule

A proactive schedule removes guesswork and ensures long-term reliability. Use the following framework as a starting point, but always defer to your furnace's specific manual.

- After every few firing cycles: Perform a quick visual inspection and clean any obvious debris from the firing chamber floor.

- On a monthly basis: Conduct a full temperature calibration check with a trusted calibration kit to verify the furnace's accuracy.

- On a quarterly basis: Perform a thorough cleaning of the chamber and inspect the heating elements and thermocouple for any signs of wear, aging, or contamination.

- Always consult your manufacturer's manual: Defer to their specific recommendations for intervals and procedures, as they supersede any general advice.

Consistent maintenance transforms your furnace from a potential variable into a reliable foundation for exceptional dental artistry.

Summary Table:

| Maintenance Task | Frequency | Key Purpose |

|---|---|---|

| Chamber Cleaning | After every few cycles | Remove contaminants for pure ceramic results |

| Temperature Calibration | Monthly | Verify accuracy to prevent under/over-firing |

| Component Inspection | Quarterly | Check heating elements and thermocouple for wear |

| Consult Manufacturer's Guide | As specified | Follow tailored procedures for optimal performance |

Ensure your dental lab's success with reliable furnace solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored to your unique needs. Our deep customization capabilities guarantee precise performance for consistent, high-quality restorations. Don't let maintenance issues compromise your work—contact us today to learn how our solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab