In powder metallurgy, a protective atmosphere box furnace is a critical piece of equipment used for the high-temperature sintering of compacted metal powders. Its primary function is to heat the "green" parts to a temperature just below their melting point, causing the individual powder particles to bond together and form a solid, dense object while preventing destructive oxidation.

The core purpose of using a protective atmosphere furnace is to control the chemical environment during sintering. By replacing the oxygen-rich air with an inert or reducing gas, the furnace ensures that the metal powders fuse into a strong, pure part without becoming brittle and weak due to oxidation.

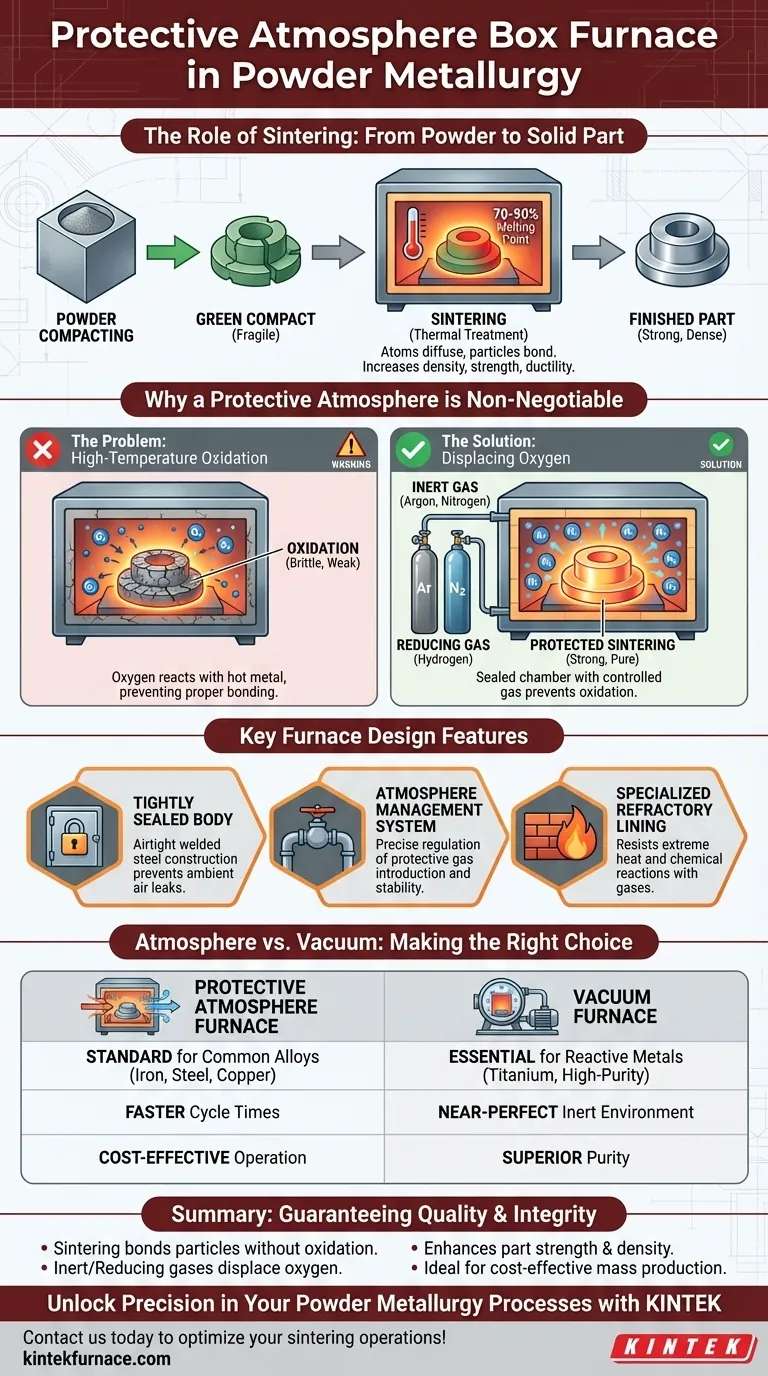

The Role of Sintering in Powder Metallurgy

From Powder to Solid Part

Powder metallurgy is a process where metal parts are formed from metallic powders. The initial step involves compacting this powder in a die under high pressure to create a fragile part, often called a "green compact."

This green compact lacks the strength and density required for most applications. Sintering is the thermal treatment that transforms it into a finished, functional component.

The Mechanism of Sintering

During sintering, the furnace heats the compact to a high temperature, typically 70-90% of the metal's absolute melting point. At this temperature, the atoms at the contact points of the powder particles diffuse across the boundaries, fusing the particles into a solid, coherent mass.

This process significantly increases the part's density, strength, and ductility without actually melting the material.

Why a Protective Atmosphere is Non-Negotiable

The Problem: High-Temperature Oxidation

The high temperatures required for sintering make metal powders extremely reactive to oxygen in the air. If heated in a normal atmosphere, the metal would rapidly oxidize.

Oxidation creates a brittle, ceramic-like layer on the metal particles, which prevents them from bonding properly. The resulting part would be weak, porous, and utterly useless for any structural application.

The Solution: Displacing Oxygen

A protective atmosphere furnace solves this by creating a tightly sealed chamber. Before and during heating, the air inside is purged and replaced with a specific gas mixture.

Common atmospheres include inert gases like argon or nitrogen, which do not react with the metal. For some applications, a reducing atmosphere containing hydrogen is used to actively remove any surface oxides that may already be present on the powder.

Key Design Features of the Furnace

Tightly Sealed Furnace Body

To maintain the integrity of the atmosphere, these furnaces are engineered to be exceptionally airtight. The body is typically constructed from welded steel plates, and the furnace door features enhanced sealing mechanisms to prevent any ambient air from leaking into the chamber.

Atmosphere Management System

The furnace is equipped with dedicated gas inlets, pipes, and control valves. This system allows for the precise introduction and regulation of the protective gas, ensuring the atmosphere remains stable and at the right composition throughout the entire sintering cycle.

Specialized Refractory Lining

The internal lining of the furnace uses special refractory bricks. These materials must not only withstand extreme heat but also be resistant to corrosion and chemical reactions with the protective atmosphere being used, particularly when using reducing gases like hydrogen.

Understanding the Trade-offs: Atmosphere vs. Vacuum

While a protective atmosphere is the standard for many applications, it is not the only solution. The primary alternative is a vacuum furnace.

Protective Atmosphere Furnaces

These furnaces are the workhorses of the powder metallurgy industry for common materials like iron, steel, and copper alloys. They generally offer faster cycle times and are often more cost-effective to operate than vacuum systems.

Vacuum Furnaces

A vacuum furnace removes virtually all gases from the chamber, creating a near-perfectly inert environment. This method is superior for sintering extremely reactive or high-purity metals like titanium, refractory metals, and certain grades of stainless steel where even trace impurities are unacceptable.

Making the Right Choice for Your Goal

The decision between using a standard protective atmosphere or a vacuum environment depends entirely on the material and the required quality of the final part.

- If your primary focus is cost-effective production of steel or common alloys: A protective atmosphere box furnace is the standard and most efficient tool for the job.

- If your primary focus is maximum purity and performance for reactive metals: A vacuum furnace is essential to prevent any contamination and achieve the desired material properties.

Ultimately, selecting the correct sintering environment is a fundamental step in guaranteeing the final part's metallurgical quality and mechanical integrity.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Use | High-temperature sintering of compacted metal powders to bond particles without oxidation. |

| Key Atmosphere | Inert gases (argon, nitrogen) or reducing gases (hydrogen) to displace oxygen. |

| Benefits | Prevents oxidation, increases part strength and density, cost-effective for common metals. |

| Ideal For | Iron, steel, copper alloys; alternative to vacuum for reactive metals. |

Unlock Precision in Your Powder Metallurgy Processes with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need cost-effective sintering for steel alloys or high-purity solutions for reactive metals, we deliver reliable, tailored equipment to enhance your part quality and efficiency.

Contact us today to discuss how our furnaces can optimize your sintering operations and achieve superior results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing