In a tube furnace, heat transfer is primarily minimized through a multi-layered system of high-temperature thermal insulation. This insulation is specifically engineered to obstruct the flow of heat from the central processing tube to the external environment. This containment ensures the furnace can reach and maintain high temperatures efficiently while keeping the outer shell cool enough to be safe.

The ultimate goal of thermal management in a tube furnace is to create a stable, uniform temperature zone. This is achieved through a two-part strategy: passively blocking heat loss with specialized insulation and actively compensating for any remaining loss with a precise temperature control system.

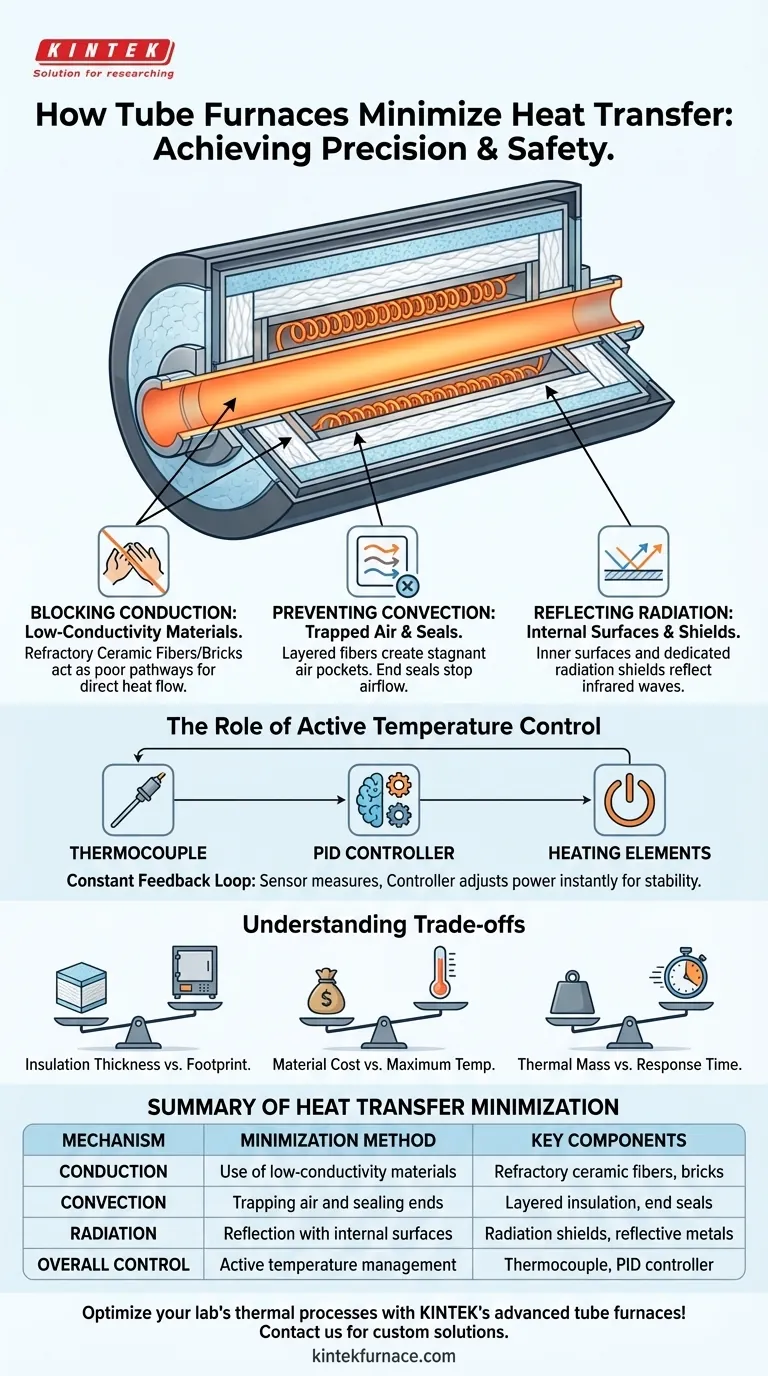

The Core Principle: Combating Heat Transfer Mechanisms

To understand how a furnace contains extreme heat, you must first understand the three ways heat moves: conduction, convection, and radiation. An effective furnace design aggressively counters all three.

Blocking Conduction with Low-Conductivity Materials

Conduction is heat transfer through direct physical contact. The primary defense against this is the insulation itself.

These materials are typically refractory ceramic fibers (made from alumina or zirconia) or dense refractory bricks. Their effectiveness comes from their chemical composition and porous microstructure, which have exceptionally low thermal conductivity, making them poor pathways for heat.

Preventing Convection with Trapped Air and Seals

Convection is heat transfer through the movement of a fluid, like air. Hot air is less dense and will rise, creating currents that carry heat away.

The insulation in a tube furnace is composed of layered fibers that create millions of tiny air pockets. This trapped air cannot circulate effectively, which essentially stops convective heat transfer through the furnace walls.

Additionally, end seals or plugs are used at the ends of the process tube to prevent hot air from escaping and cool ambient air from entering, which would disrupt the temperature uniformity.

Reflecting Radiation with Internal Surfaces

Radiation is heat transfer via electromagnetic waves (specifically infrared). At the high temperatures found in a furnace, radiation becomes a dominant form of heat transfer.

While insulation materials primarily block conduction and convection, their internal surfaces also play a role in reflecting radiant heat back toward the center of the furnace. In very high-temperature or vacuum furnaces, dedicated radiation shields made of reflective metals like molybdenum may be layered inside the insulation to further enhance this effect.

The Role of Active Temperature Control

Insulation provides passive control—it slows the inevitable loss of heat. An active control system is required to achieve and hold a precise setpoint temperature.

The Thermocouple as the Sensor

A thermocouple is a sensor placed near the heating elements and the process tube. Its sole job is to measure the temperature in the hot zone accurately and in real-time.

The PID Controller as the Brain

The thermocouple sends its reading to a temperature controller, which is the furnace's brain. This controller continuously compares the actual temperature to the user's desired setpoint.

If the temperature drops even slightly (due to heat loss not blocked by insulation), the controller instantly increases power to the heating elements. If it overshoots, it reduces power. This constant feedback loop, often managed by a PID algorithm, is what ensures exceptional thermal stability.

Understanding the Trade-offs

The design of a furnace's thermal management system involves balancing competing priorities.

Insulation Thickness vs. Furnace Footprint

More insulation results in better energy efficiency and a cooler external surface. However, it also increases the furnace's overall size, weight, and cost.

Material Cost vs. Maximum Temperature

Insulation materials are rated for specific temperatures. Standard ceramic fiber is effective up to around 1200°C. For processes requiring 1700°C or more, more advanced and significantly more expensive materials like high-purity alumina or zirconia fibers are necessary.

Thermal Mass vs. Response Time

Dense, heavy insulation (high thermal mass) is excellent for maintaining a highly stable temperature. The downside is that it takes a long time to heat up and cool down. A furnace with lightweight fiber insulation (low thermal mass) will have much faster heat-up and cool-down rates.

Making the Right Choice for Your Application

The optimal thermal design depends entirely on your scientific or industrial goal.

- If your primary focus is maximum temperature stability: Look for a furnace with thick, multi-layered insulation and a precise PID controller to hold a setpoint with minimal deviation.

- If your primary focus is rapid cycling (fast heat-up/cool-down): Prioritize a furnace with low thermal mass insulation, such as lightweight ceramic fiber boards.

- If your primary focus is energy efficiency and operational safety: Ensure the furnace has high-quality insulation that results in a low external shell temperature during operation.

Understanding these principles of thermal management empowers you to select and operate your tube furnace with greater precision and efficiency.

Summary Table:

| Heat Transfer Mechanism | Minimization Method | Key Components |

|---|---|---|

| Conduction | Use of low-conductivity materials | Refractory ceramic fibers, bricks |

| Convection | Trapping air and sealing ends | Layered insulation, end seals |

| Radiation | Reflection with internal surfaces | Radiation shields, reflective metals |

| Overall Control | Active temperature management | Thermocouple, PID controller |

Optimize your lab's thermal processes with KINTEK's advanced tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your efficiency and precision!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the safety and usability features of tube furnaces? Essential for Precise Material Processing

- What is the significance of flexible atmosphere control in an atmosphere tube furnace? Unlock Precise Material Engineering

- What types of atmospheres can be used in a rotary tube furnace? Optimize Your Material Processing with Precision Control

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- What are some standard models of tube furnaces and their specifications? Find the Perfect Fit for Your Lab

- What are the advantages of corundum tube furnaces? Unlock High-Temp, Corrosion-Resistant Processing

- How is heat transferred to the materials inside the tube furnace? Master Uniform Heating for Your Lab

- What are common applications of Tube Furnaces? Unlock Precision in Material Synthesis and Heat Treatment