At its core, an atmosphere box furnace is utilized in materials research to precisely control both temperature and the gaseous environment surrounding a sample. This dual control allows researchers to simulate specific conditions, study how a material behaves and degrades, and synthesize entirely new materials with unique properties. It moves research from simple heating in air to a highly controlled, repeatable scientific process.

The true value of an atmosphere furnace is its ability to isolate variables. By removing or introducing specific gases, researchers can definitively determine whether a material's failure or success at high temperatures is due to the heat itself or a chemical reaction with its environment.

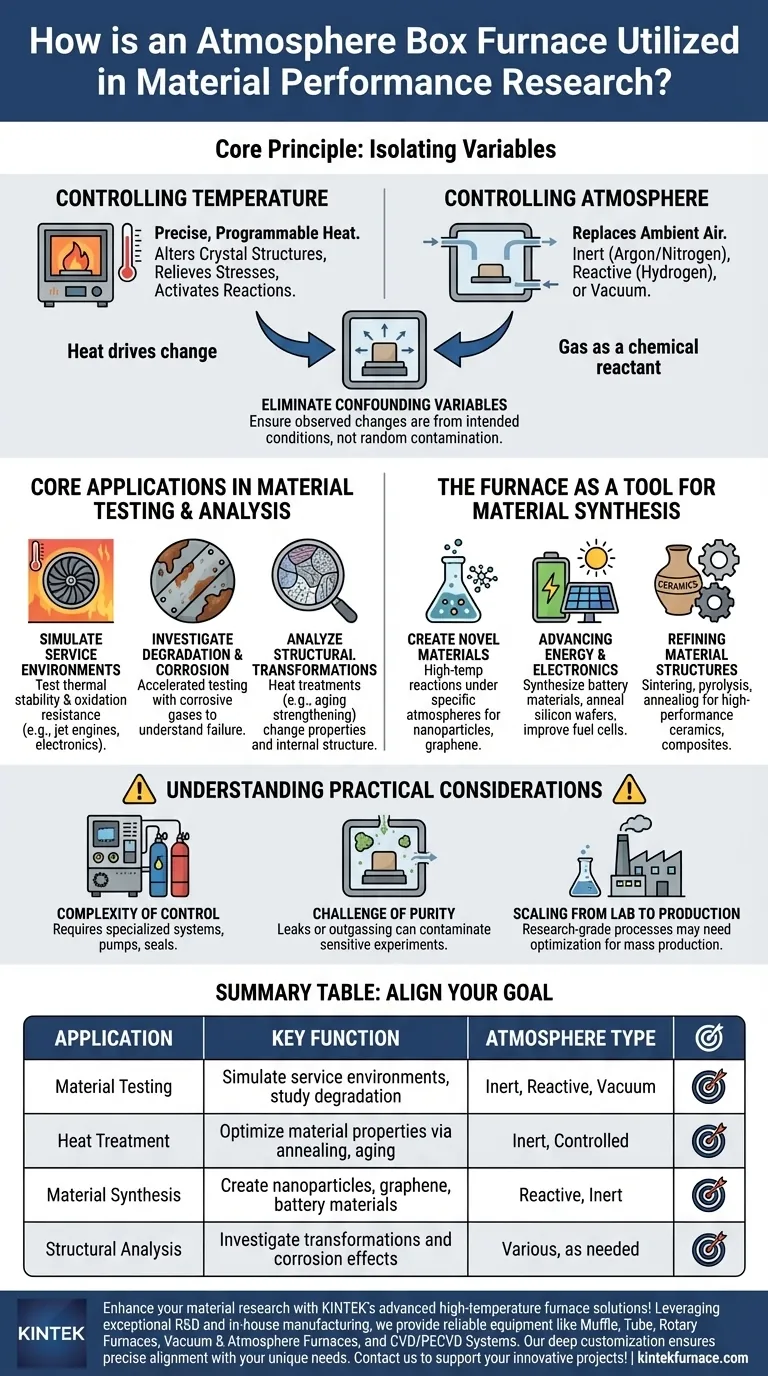

The Fundamental Principle: Isolating Variables

An atmosphere box furnace provides a sealed chamber where the environment can be meticulously managed. This control is the key to understanding complex material behaviors.

Controlling Temperature

Heat is a primary driver of change in materials. It can alter crystal structures, relieve internal stresses, or provide the activation energy needed for chemical reactions to occur. A furnace provides precise, programmable temperature control.

Controlling the Atmosphere

The gas surrounding a material is not passive; it is a chemical reactant. An atmosphere furnace allows researchers to replace ambient air with a specific, controlled atmosphere.

This can be an inert atmosphere (like Argon or Nitrogen) to prevent oxidation and other unwanted reactions, a reactive atmosphere (like Hydrogen) to induce reduction, or a vacuum to remove atmospheric influence altogether.

Why This Control is Crucial

By controlling both temperature and atmosphere, researchers can eliminate confounding variables. This ensures that observed changes in the material—such as hardening, embrittlement, or decomposition—are a direct result of the intended experimental conditions, not random contamination from the air.

Core Applications in Material Testing & Analysis

The primary use of these furnaces is to understand how existing materials perform under stress, providing data to improve them or predict their lifespan.

Simulating Service Environments

Many materials, from jet engine turbines to electronic components, operate in hot, demanding environments. The furnace can replicate these conditions to test for thermal stability and oxidation resistance.

Investigating Degradation and Corrosion

Researchers can intentionally introduce specific corrosive gases into the furnace chamber. This allows for accelerated testing to study failure mechanisms and develop more resilient materials.

Analyzing Structural Transformations

Controlled heating and cooling cycles, known as heat treatments, are used to change a material's properties. For example, researchers study the aging strengthening of new aluminum alloys by heating samples to specific temperatures (e.g., 180-200°C) for varying times.

Subsequent hardness testing and microscopic observation reveal how the treatment altered the alloy's internal structure and mechanical properties.

The Furnace as a Tool for Material Synthesis

Beyond testing, atmosphere furnaces are essential tools for creating next-generation materials that would be impossible to make in open air.

Creating Novel Materials

Under a specific atmosphere, high-temperature heating can drive unique chemical reactions. Heating metal oxides in an inert atmosphere can produce metal nanoparticles, while heating carbon-based precursors in a reducing atmosphere can be used to synthesize materials like graphene.

Advancing Energy & Electronics

This technology is critical for new energy materials. It is used in the high-temperature solid-state reactions needed to create cathode materials for lithium-ion batteries.

In solar cell production, furnaces are used for the doping and annealing of silicon wafers to improve their photoelectric conversion efficiency. They also support the synthesis of fuel cell electrolytes and advanced hydrogen storage materials.

Refining Material Structures

Processes like sintering, pyrolysis, and annealing are performed in a controlled atmosphere to produce high-performance ceramics, glass, and composites. These processes refine a material's internal structure, enhancing its properties for demanding applications.

Understanding the Practical Considerations

While powerful, atmosphere furnaces come with their own set of challenges that researchers must manage.

The Complexity of Control

Maintaining a pure, sealed atmosphere requires specialized gas handling systems, vacuum pumps, and robust seals. This makes the equipment more complex and costly to operate than a standard furnace that simply heats in air.

The Challenge of Purity

Achieving and maintaining a truly pure atmosphere is difficult. Minor leaks or the outgassing of volatile elements from the sample or furnace insulation can contaminate the experiment, affecting the results of highly sensitive tests.

Scaling From Lab to Production

Research-grade furnaces are typically smaller than their industrial counterparts. A process perfected on a small sample in a lab furnace may face new challenges when scaled up for mass production, requiring further optimization.

Aligning the Furnace with Your Research Goal

To effectively utilize this tool, you must match its capabilities to your specific objective.

- If your primary focus is testing material durability: Use the furnace to simulate harsh service environments and precisely identify failure points related to heat and atmospheric reactions.

- If your primary focus is process optimization: Use controlled heat treatments, like annealing or aging, to systematically refine a material's microstructure and enhance its mechanical properties.

- If your primary focus is synthesizing new materials: Leverage a reactive or inert atmosphere to enable chemical reactions that are impossible in open air, creating novel structures like advanced ceramics or nanoparticles.

Ultimately, the atmosphere box furnace transforms material science from an observational practice into a predictive and engineering-driven discipline.

Summary Table:

| Application | Key Function | Atmosphere Type |

|---|---|---|

| Material Testing | Simulate service environments, study degradation | Inert, Reactive, Vacuum |

| Heat Treatment | Optimize material properties via annealing, aging | Inert, Controlled |

| Material Synthesis | Create nanoparticles, graphene, battery materials | Reactive, Inert |

| Structural Analysis | Investigate transformations and corrosion effects | Various, as needed |

Enhance your material research with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you achieve superior results in material testing and synthesis. Contact us today to discuss how we can support your innovative projects!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance