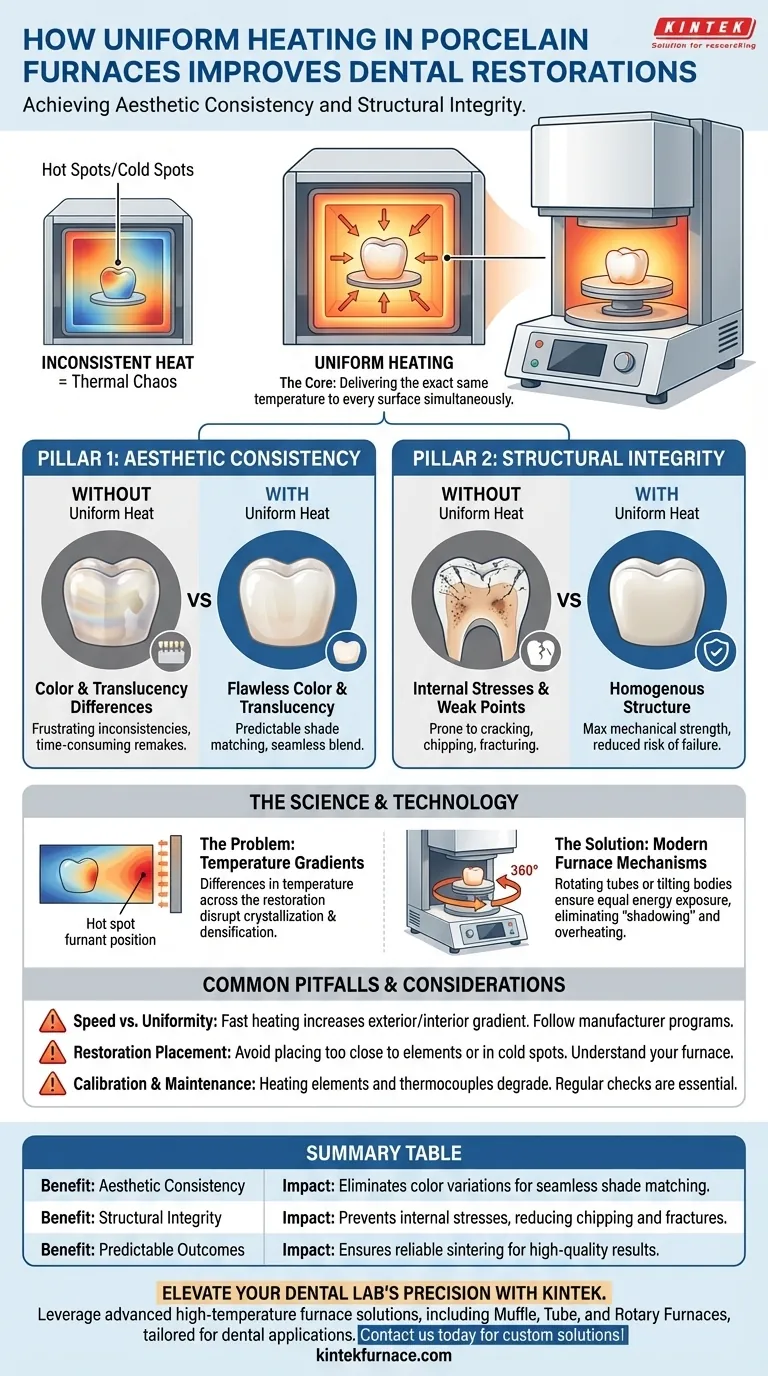

In short, uniform heating in a porcelain furnace is the controlling factor for achieving both aesthetic consistency and structural integrity in dental restorations. By delivering the exact same temperature to every surface of the restoration simultaneously, it eliminates color variations and prevents the formation of internal weak points, resulting in a product that is both beautiful and durable.

The core problem is that inconsistent heat creates unpredictable results. Uniform heating eliminates this thermal chaos, ensuring every part of the restoration undergoes the exact same physical and chemical transformation, leading to predictable, high-quality outcomes every time.

The Two Pillars of Restoration Quality

Every dental professional aims for restorations that are indistinguishable from natural teeth and can withstand the forces of the oral environment. Uniform heating is the technical process that makes achieving these two goals possible.

Achieving Flawless Color and Translucency

Inconsistent heating is a primary cause of aesthetic failure. If one part of a crown is even slightly hotter or cooler than another during the firing cycle, it will result in visible color and translucency differences.

These temperature gradients, or "hot spots" and "cold spots," alter the porcelain's reaction. This leads to frustrating inconsistencies that require time-consuming remakes and can compromise a patient's satisfaction.

Uniform heating ensures that the entire restoration—from the thickest to the thinnest areas—reaches the target temperatureProfiling in a data pipeline is a process of analyzing and summarizing datasets to understand their characteristics, quality, and structure. It involves gathering descriptive statistics and metadata to create a comprehensive overview of the data. This process is crucial for several reasons:

Data Quality Assurance: Profiling helps identify data quality issues such as missing values, inconsistencies, outliers, and incorrect data types. By detecting these problems early, you can implement data cleaning and transformation steps to ensure the reliability of your data.

Understanding Data Structure: It provides insights into the schema of your data, including the number of columns, column names, and data types. This is essential for validating that the data conforms to expected formats and for planning data integration and transformation tasks.

Informing Data Transformation: The statistics generated during profiling, like minimum, maximum, mean, and standard deviation, inform how you should normalize, scale, or bin data for machine learning models or other analytical purposes.

Schema Evolution: Profiling can track changes in data structure and distribution over time. This helps in managing schema evolution and ensuring that perubahan in the data source do not break downstream processes.

Optimizing Performance: Understanding data characteristics such as cardinality (the number of unique values in a column) can help optimize database queries and data processing workflows.

In essence, data profiling is a foundational step in any data-intensive project, providing the necessary intelligence to build robust, reliable, and efficient data pipelines. at the same rate. This consistency is what allows for perfect, predictable shade matching that blends seamlessly with the patient's natural dentition.

Ensuring Predictable Structural Integrity

Aesthetics are meaningless if the restoration fails. Uniform heating is just as critical for the mechanical strength and longevity of the final product.

The firing process, known as sintering, fuses porcelain particles together to create a dense, strong material. When heating is uneven, this process becomes non-uniform.

Some areas may become fully densified while others remain porous and weak. This creates internal stresses within the material, making it significantly more prone to cracking, chipping, or fracturing under normal chewing forces.

The Science of Thermal Consistency

To appreciate the benefit, it's helpful to understand the physical process at play and how modern furnaces are engineered to control it.

The Problem of Temperature Gradients

A temperature gradient is simply a difference in temperature across a physical object. In a furnace, this can be caused by the position of heating elements, a poorly designed muffle, or even 장애물 around the restoration itself. These gradients are the enemy of high-quality porcelain work.

The Role of Crystallization and Densification

During the firing cycle, porcelain undergoes crystallization and densification. For materials like lithium disilicate, this is the phase where the material gains its final strength and color. This transformation must occur evenly throughout the entire volume of the restoration.

Uneven heating causes этих processes to happen at different rates, leading to a non-homogenous structure with built-in weak points.

Modern Furnace Mechanisms

To combat this, advanced porcelain furnaces employ specific engineering solutions. Some feature furnace tubes that rotate 360 degrees or furnace bodies that tilt.

This movement constantly changes the restoration's orientation relative to the heat source, ensuring that all surfaces receive equal energy exposure and that no single area is "shadowed" or overheated.

Common Pitfalls and Considerations

Even with the best equipment, achieving perfect uniformity requires awareness of potential challenges.

Speed vs. Uniformity

A very fast heating rate can be efficient, but it also increases the risk of creating a significant temperature gradient between the outside and inside of a restoration. The exterior heats up much faster than the core, inducing stress. It is crucial to follow manufacturer-validated programs that balance speed with thermal consistency.

The Impact of Restoration Placement

Careless placement of the restoration within the furnace can undermine the equipment's design. Placing it too close to a heating element or in a known cold spot can negate the benefits of a uniform furnace. Technicians must understand the specific thermal characteristics of their equipment.

The Need for Calibration and Maintenance

A furnace's ability to heat uniformly degrades over time. Heating elements age, and thermocouples (temperature sensors) can lose accuracy. Regular calibration and maintenance are not optional; they are essential for ensuring your furnace continues to deliver predictable, high-quality results.

Making the Right Choice for Your Goal

Understanding the principle of uniform heating allows you to diagnose issues and make better decisions for your lab.

- If your primary focus is aesthetics: Uniform heating is non-negotiable for eliminating color variations and achieving perfect shade matching.

- If your primary focus is durability: Uniform heating is critical for creating a homogenous, dense structure that resists chipping and fracture, reducing remakes and ensuring clinical success.

- If you are evaluating a new furnace: Look beyond the marketing and ask about the specific mechanisms it uses to ensure even heat distribution, such as muffle design and rotational capabilities.

Ultimately, mastering the principles of thermal processing empowers you to deliver consistently superior restorations.

Summary Table:

| Benefit | Impact on Dental Restorations |

|---|---|

| Aesthetic Consistency | Eliminates color and translucency variations for seamless shade matching |

| Structural Integrity | Prevents internal stresses and weak points, reducing chipping and fractures |

| Predictable Outcomes | Ensures reliable sintering and crystallization for high-quality results every time |

Elevate your dental lab's precision and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for dental applications. Our strong deep customization capability ensures your unique experimental requirements are met, delivering uniform heating for flawless restorations. Contact us today to discuss how our furnaces can enhance your workflow and outcomes!

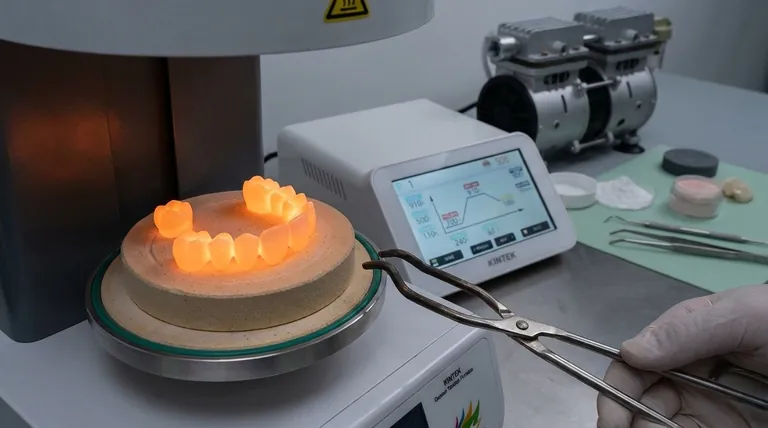

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency