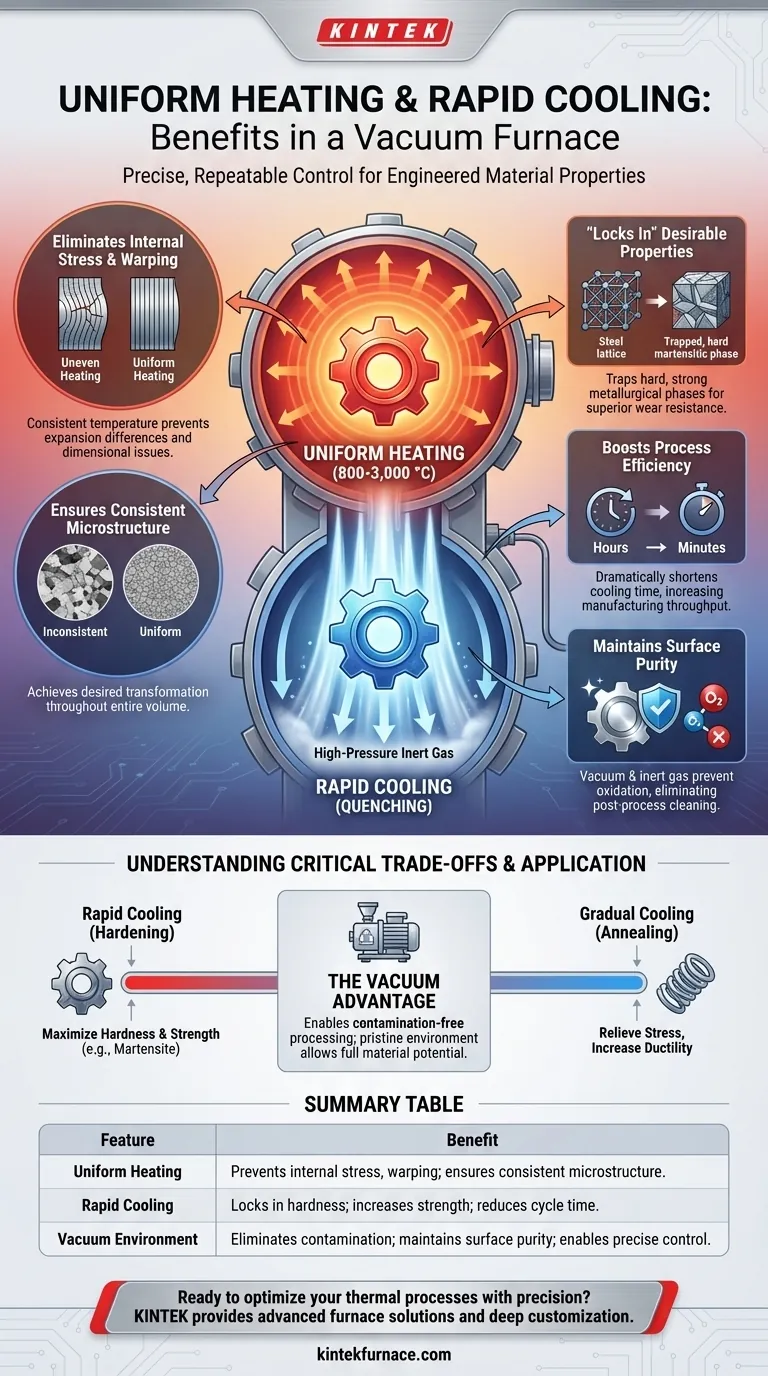

In a vacuum furnace, uniform heating ensures that every part of a component, regardless of its shape or thickness, reaches the same temperature at the same time. This consistency prevents internal stresses, warping, and defects. Rapid cooling, or quenching, then "locks in" the desired metallurgical properties achieved during heating while dramatically shortening the overall process time for greater efficiency.

The core purpose of combining uniform heating with rapid cooling is to gain precise, repeatable control over a material's final microstructure. This allows for the engineering of specific properties like hardness and strength, free from the contamination and inconsistencies that plague conventional atmospheric furnaces.

The Role of Uniform Heating in Material Integrity

Uniform heating is the foundation for achieving predictable, high-quality results. It eliminates thermal gradients—temperature differences across a part—which are a primary source of process failure.

Eliminating Internal Stress and Warping

When different sections of a part heat up at different rates, they expand unevenly. This creates internal stresses that can lead to distortion, warping, or even cracking.

By ensuring the entire component reaches a uniform temperature (often within a range of 800-3,000 °C), a vacuum furnace guarantees that expansion is consistent, preserving the part's dimensional accuracy.

Ensuring a Consistent Microstructure

The properties of a metal are dictated by its internal crystal structure, known as its microstructure. Processes like hardening or annealing are designed to manipulate this structure.

Uniform heating ensures that the desired transformation—such as creating a fully austenitic state before hardening—occurs throughout the entire volume of the material. This prevents soft spots in a hardened component or inconsistent grain structures that compromise performance.

The Power of Rapid Cooling (Quenching)

Once the material is uniformly heated to the correct temperature, the cooling phase determines its final properties. Rapid cooling is a deliberate, controlled process designed to achieve specific outcomes.

"Locking In" Desirable Properties

For processes like hardening, the goal is to cool the material so quickly that the atomic structure doesn't have time to revert to its softer, more stable state.

This rapid quench, typically using high-pressure inert gas like nitrogen or argon, traps a hard, strong metallurgical phase (e.g., martensite in steel). This is how modern vacuum furnaces produce components with superior strength and wear resistance.

Boosting Process Efficiency

Compared to slow, conventional cooling methods, rapid quenching can reduce the cooling portion of a furnace cycle from hours to minutes.

This significant reduction in cycle time directly increases manufacturing throughput and lowers operational costs, making the entire process more economically efficient.

Maintaining Surface Purity

The vacuum environment prevents oxidation during heating. Rapidly cooling with an inert gas ensures the part remains in a controlled atmosphere until it is no longer hot enough to react with air.

This preserves the clean, bright finish of the component and avoids the need for post-process cleaning, which is often required with traditional furnaces.

Understanding the Critical Trade-offs

While rapid cooling is a powerful tool, it is not universally required. The ideal cooling rate is entirely dependent on the desired outcome for the material.

Rapid Cooling vs. Gradual Cooling

Rapid cooling (quenching) is used to maximize hardness and strength. It intentionally induces a level of stress to achieve these properties and is essential for hardening processes.

Gradual cooling (annealing) is used to achieve the opposite effect. A slow, controlled cool-down allows internal stresses to relieve, resulting in a softer, more ductile, and more easily machinable material. Choosing the wrong cycle can ruin the component.

The Vacuum Is the Enabling Factor

Neither uniform heating nor controlled cooling would be as effective without the vacuum. The primary benefit of the furnace is creating a low-pressure environment that prevents contamination from oxygen and other gases.

This pristine environment is what allows the thermal processing to achieve the material's full potential without introducing surface oxides or other impurities that degrade its integrity.

How to Apply This to Your Goal

The specific combination of heating and cooling cycles is selected to achieve a precise metallurgical objective.

- If your primary focus is maximizing hardness and strength: You need uniform heating followed by a very rapid quench to lock in a hard, martensitic microstructure.

- If your primary focus is relieving stress and increasing ductility: You need uniform heating followed by a slow, controlled cooling cycle, a process known as annealing.

- If your primary focus is creating clean, strong joints via brazing: You need uniform heating to ensure the filler metal flows evenly, followed by a cooling cycle optimized to prevent stress in the joined materials.

Ultimately, mastering thermal processing in a vacuum furnace comes down to using precise temperature and time control to dictate the material's final form and function.

Summary Table:

| Feature | Benefit |

|---|---|

| Uniform Heating | Prevents internal stress, warping, and ensures consistent microstructure |

| Rapid Cooling | Locks in hardness, increases strength, and reduces cycle time |

| Vacuum Environment | Eliminates contamination, maintains surface purity, and enables precise control |

Ready to optimize your thermal processes with precision? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for enhanced material quality and efficiency. Contact us today to discuss how our tailored solutions can benefit your laboratory!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision