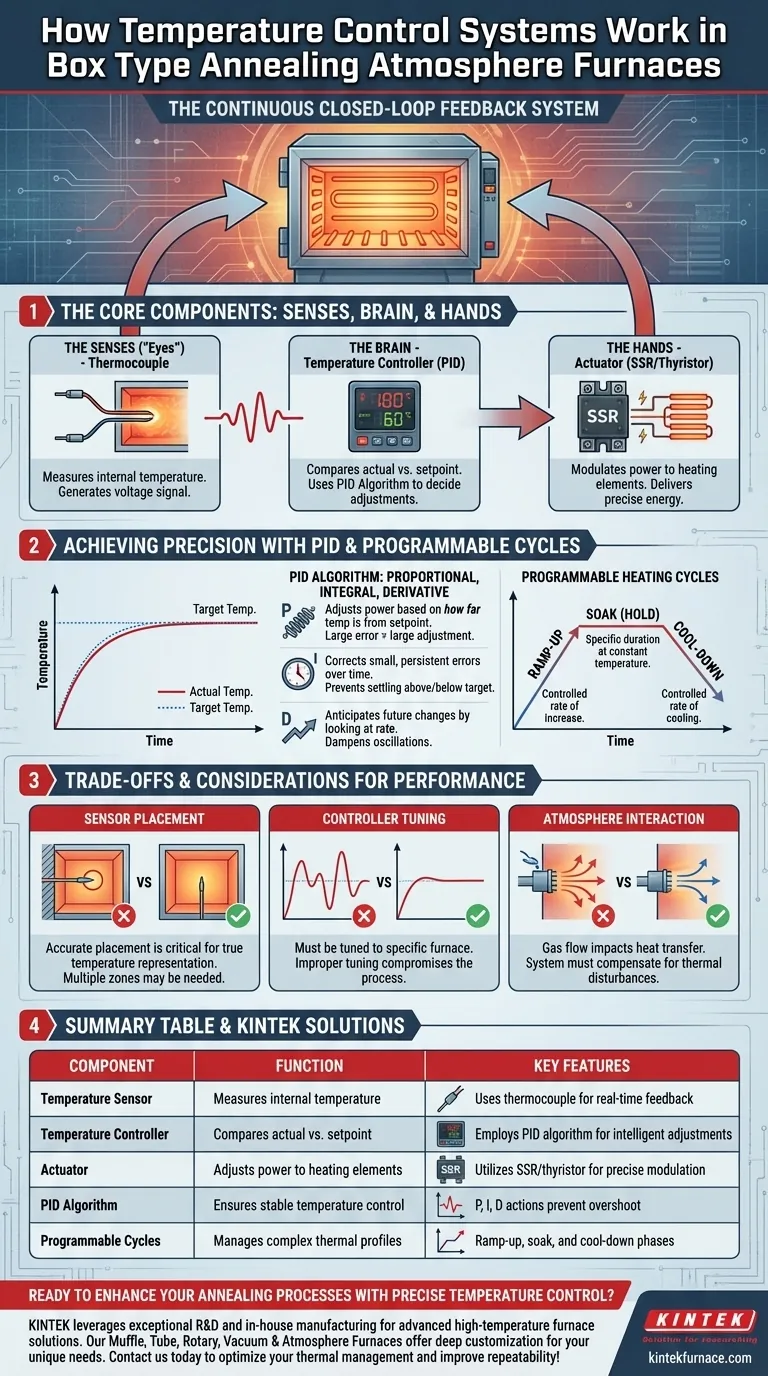

At its core, the temperature control system in a box-type annealing furnace operates as a continuous, closed-loop feedback system. It precisely measures the internal temperature using a sensor, compares that measurement to a pre-set target value in a controller, and then automatically adjusts the power supplied to the heating elements to maintain the exact thermal conditions required for the annealing process.

The system's purpose is not just to heat the furnace, but to execute a precise thermal profile with high fidelity. It achieves this by intelligently managing the flow of energy based on real-time feedback, ensuring the material being treated acquires its desired metallurgical properties.

The Core Components of Temperature Control

A modern furnace temperature control system is comprised of three critical, interconnected parts that function like the senses, brain, and hands of a single organism.

The Temperature Sensor (The "Eyes")

The system's "eyes" inside the furnace chamber is a thermocouple. This robust sensor is designed to withstand extreme heat.

A thermocouple works by generating a tiny voltage that changes predictably with temperature. This signal is sent from the furnace to the controller, providing a constant, real-time measurement of the internal environment.

The Temperature Controller (The "Brain")

The temperature controller is the central processing unit. It receives the voltage signal from the thermocouple and converts it into a temperature reading.

Its primary job is to compare this actual temperature to the desired temperature (the setpoint). Modern controllers use a sophisticated PID (Proportional-Integral-Derivative) control algorithm to decide how to react to any deviation. This algorithm allows for intelligent adjustments, preventing temperature overshoots or slow response times.

The Actuator (The "Hands")

The actuator translates the controller's decision into action. Based on the PID algorithm's output, the controller sends a signal to an actuator, which is typically a Solid-State Relay (SSR) or a thyristor regulator.

This device precisely modulates the electrical power flowing to the furnace's heating elements. It can deliver full power for rapid heating, partial power to maintain a steady temperature, or no power during cooling phases.

How the System Achieves Precision

The combination of these components enables the execution of complex, multi-stage annealing cycles far beyond simple heating.

The PID Algorithm in Action

Unlike a basic thermostat that is simply on or off, a PID controller makes nuanced adjustments:

- Proportional: It adjusts power based on how far the current temperature is from the setpoint. A large difference prompts a large adjustment.

- Integral: It corrects for small, persistent errors over time, ensuring the system doesn't settle slightly above or below the target.

- Derivative: It anticipates future changes by looking at the rate of temperature change, helping to dampen oscillations and prevent overshooting the target.

Programmable Heating Cycles

This precise control allows operators to program entire thermal profiles. Modern controllers can manage a complete, automated cycle that includes:

- Ramp-up: A controlled rate of temperature increase (e.g., 10°C per minute).

- Soak (or Hold): A specific duration where the temperature is held constant with high stability.

- Cool-down: A controlled rate of cooling, which is often as critical to the material's final properties as the heating itself.

Understanding the Trade-offs and Considerations

While highly effective, the performance of the system depends on several factors.

Sensor Placement and Accuracy

The location of the thermocouple is critical. If placed incorrectly, it may not represent the true temperature of the workpiece. For very large furnaces, multiple thermocouples and control zones may be necessary to ensure uniform heating.

PID Controller Tuning

A PID controller is not "plug and play." It must be tuned to the specific thermal characteristics of the furnace. Improper tuning can lead to the temperature oscillating wildly around the setpoint or taking too long to stabilize, compromising the annealing process.

Interaction with the Furnace Atmosphere

The atmosphere control system, which injects protective gases, directly impacts heat transfer. The flow of gas can carry heat away from the workpiece. The temperature control system must be responsive enough to compensate for these thermal disturbances to maintain a stable temperature.

Making the Right Choice for Your Process

Understanding this system empowers you to ensure process quality and make informed decisions.

- If your primary focus is process repeatability and quality: Insist on a furnace with a modern, programmable PID controller to guarantee that every batch undergoes the exact same thermal profile.

- If your primary focus is troubleshooting a process issue: Investigate the system in order. First, verify the thermocouple is positioned correctly and functioning. Second, review the PID tuning parameters in the controller. Finally, check that the actuator (SSR) and heating elements are responding correctly.

- If your primary focus is purchasing new equipment: Specify the required temperature accuracy (e.g., ±1°C) and the complexity of the heating cycles you need to run. This ensures the controller and system are matched to your metallurgical requirements.

Ultimately, this precise and dynamic control over temperature is the key technology that makes successful, repeatable annealing possible.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Temperature Sensor | Measures internal temperature | Uses thermocouple for real-time feedback |

| Temperature Controller | Compares actual vs. setpoint temperature | Employs PID algorithm for intelligent adjustments |

| Actuator | Adjusts power to heating elements | Utilizes SSR or thyristor for precise modulation |

| PID Algorithm | Ensures stable temperature control | Proportional, Integral, Derivative actions prevent overshoot |

| Programmable Cycles | Manages complex thermal profiles | Includes ramp-up, soak, and cool-down phases |

Ready to enhance your annealing processes with precise temperature control? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our expertise can optimize your thermal management and improve process repeatability!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What materials are used in the construction of a retort furnace? Discover Key Components for High-Temp Control

- What factors should be considered when selecting a controlled atmosphere furnace? Ensure Process Success with Expert Guidance

- What are the key applications of low vacuum atmosphere furnaces? Boost Efficiency in Heat Treatment

- What are the thermal insulation properties of argon in furnace applications? Unlock Material Purity and Efficiency

- How does constant temperature heating equipment affect catalyst precursors? Precision Control for Perovskite Quality

- What are the functions of sample ports and flame curtains in atmospheric furnaces? Ensure Control and Safety in Heat Treatment

- What is an example of gas used for annealing titanium alloys, and why? Discover the Essential Role of Argon for Superior Results

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment