At its core, a dental sintering furnace is a high-temperature oven that transforms a chalky, oversized dental restoration into its final, dense, and strong state. It accomplishes this by heating the material—most commonly zirconia—to a precise temperature just below its melting point. This controlled thermal process causes the material's individual particles to fuse together, shrinking the restoration to its exact intended size and imparting the hardness and durability required for clinical use.

Sintering is not merely heating; it is a precisely controlled transformation. By heating a material to a specific temperature without melting it, the furnace causes its particles to fuse, leading to predictable shrinkage and the development of the final strength and esthetics required for a durable dental restoration.

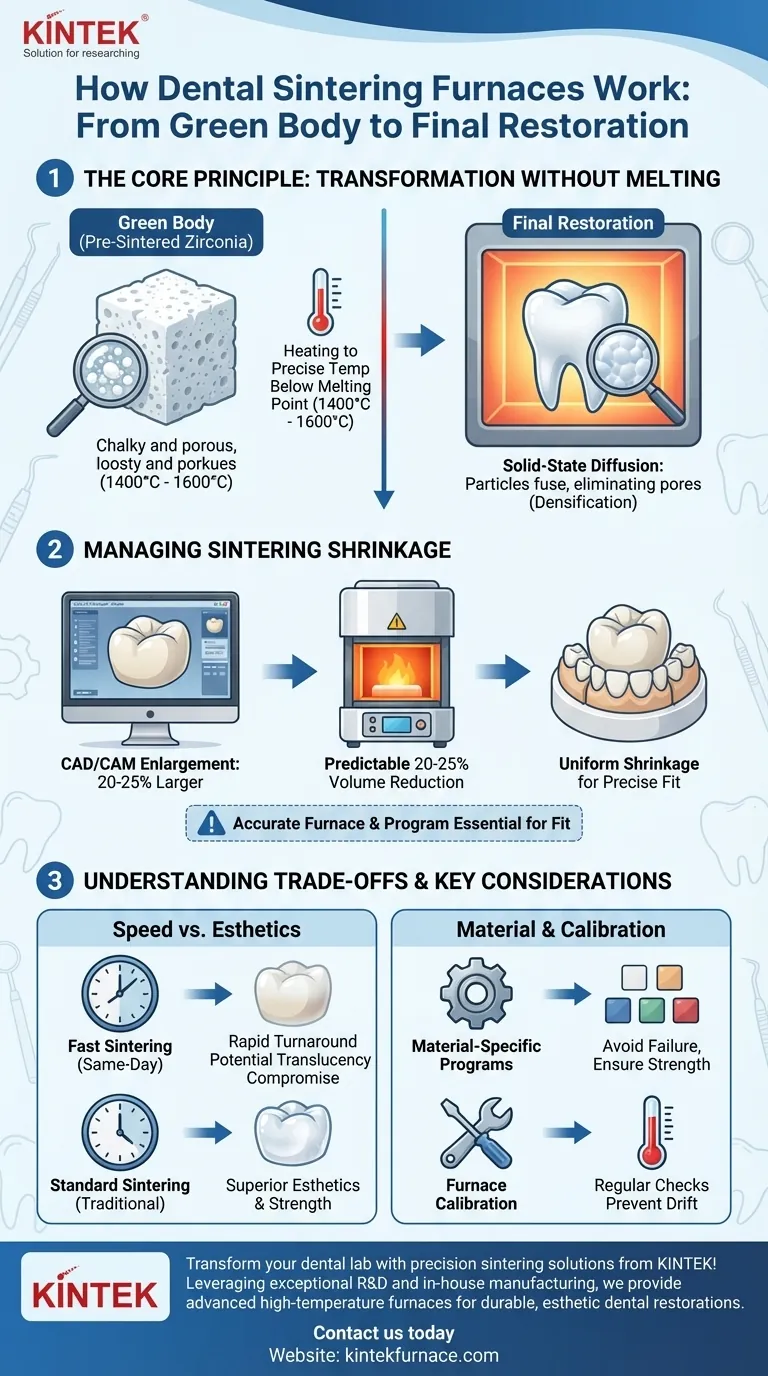

The Core Principle: Transformation Without Melting

The magic of sintering lies in its ability to fundamentally change a material's properties while perfectly preserving its designed shape. This happens through a process of solid-state diffusion.

From "Green Body" to Final Restoration

After a dental restoration is designed in CAD software, it is milled from a block of zirconia. In this pre-sintered state, often called a "green body" or "white state," the material is soft, chalky, and porous.

The sintering furnace takes this fragile green body and converts it into a dense, non-porous ceramic that is among the strongest materials used in dentistry.

The Atomic-Level Process

The furnace's extreme heat gives the individual particles within the zirconia enough energy to move and bond to one another. As they fuse together, the microscopic pores and voids between them are eliminated.

This process, known as densification, is what gives the final restoration its immense strength and translucent appearance.

The Critical Role of Temperature Control

The entire process hinges on reaching a temperature that is high enough to activate particle bonding but low enough to avoid melting.

If the material were to melt, the intricate anatomical details of the crown or bridge would be lost. Modern computerized furnaces maintain temperature accuracy to within a few degrees to ensure a perfect outcome.

Managing the Inevitable: Sintering Shrinkage

The most critical factor to manage in sintering is the significant, yet predictable, shrinkage that occurs. Understanding this is key to achieving a restoration that fits.

Why Shrinkage Occurs

The shrinkage is a direct result of the densification process. As the millions of tiny voids between material particles are eliminated, the overall volume of the restoration must decrease.

For dental zirconia, this shrinkage is substantial, typically ranging from 20% to 25%.

The "Enlargement Factor"

To compensate for this, the restoration is intentionally and precisely milled in an oversized state. The CAD/CAM software automatically calculates the required enlargement based on the specific zirconia block being used, as each manufacturer's material has a unique shrinkage factor.

The Impact on Final Fit

The accuracy of the final restoration's fit depends entirely on predictable and uniform shrinkage. This is why a high-quality, properly calibrated furnace and the correct sintering program are non-negotiable for producing clinically acceptable results.

Understanding the Trade-offs and Key Considerations

While the principle is straightforward, achieving optimal results requires an understanding of the variables and potential pitfalls.

Speed vs. Esthetics

Modern furnaces offer "fast" or "speed" sintering cycles that can be completed in a fraction of the time of traditional cycles. While essential for same-day dentistry, these rapid cycles can sometimes compromise the material's final translucency.

Slower, conventional cycles generally allow for more complete crystallization, often resulting in superior esthetics. The choice depends on balancing the clinical need for speed against the desired aesthetic outcome.

Material-Specific Programs

There is no "one-size-fits-all" sintering program. Different types of zirconia (e.g., high-strength vs. high-translucency) and other ceramic materials have unique, manufacturer-specified temperature profiles.

Using the wrong program for a given material is a primary cause of restoration failure, leading to poor fit, inadequate strength, or fracture.

Furnace Calibration

The accuracy of the furnace's thermocouple, which measures temperature, is paramount. Over time, these can drift. A furnace that is firing even slightly hotter or cooler than programmed will result in incorrect shrinkage and compromised material properties. Regular calibration is essential maintenance.

Making the Right Choice for Your Goal

The sintering process must be tailored to the specific goals of the restoration and the dental practice.

- If your primary focus is maximum esthetics and strength: Utilize the manufacturer's recommended standard (slower) sintering cycle and ensure your furnace's temperature is regularly calibrated.

- If your primary focus is rapid turnaround for same-day dentistry: Invest in a furnace specifically designed for speed sintering and use only the materials that have been fully validated for that exact cycle.

- If you are troubleshooting poor fit or fractures: Your first step should be to suspect the sintering process. Verify you are using the correct program for your specific material and have the furnace's temperature calibration checked.

Mastering the principles of sintering is the key to transforming a digital design into a clinically successful and durable physical restoration.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Heating zirconia just below melting point to fuse particles via solid-state diffusion, leading to densification. |

| Shrinkage | Predictable 20-25% volume reduction; compensated by CAD/CAM enlargement for precise fit. |

| Temperature Control | Critical for avoiding melting; modern furnaces maintain accuracy within a few degrees for uniform results. |

| Cycle Types | Standard cycles for better esthetics/strength; fast cycles for same-day dentistry with potential trade-offs. |

| Material Specificity | Requires manufacturer-specific programs to prevent failure; regular furnace calibration is essential. |

Transform your dental lab with precision sintering solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met for durable, esthetic dental restorations. Contact us today to enhance your sintering process and achieve superior clinical outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time