The mature technology of a tube furnace directly translates into superior operational reliability, lower running costs, and greater ease of use. Because its design has been refined over decades, each component works in concert to deliver predictable and efficient performance, minimizing unexpected failures and complex maintenance.

A tube furnace's mature design isn't about being old; it's about being perfected. This evolution results in a highly reliable and cost-effective system where every component is optimized for performance, low maintenance, and energy efficiency.

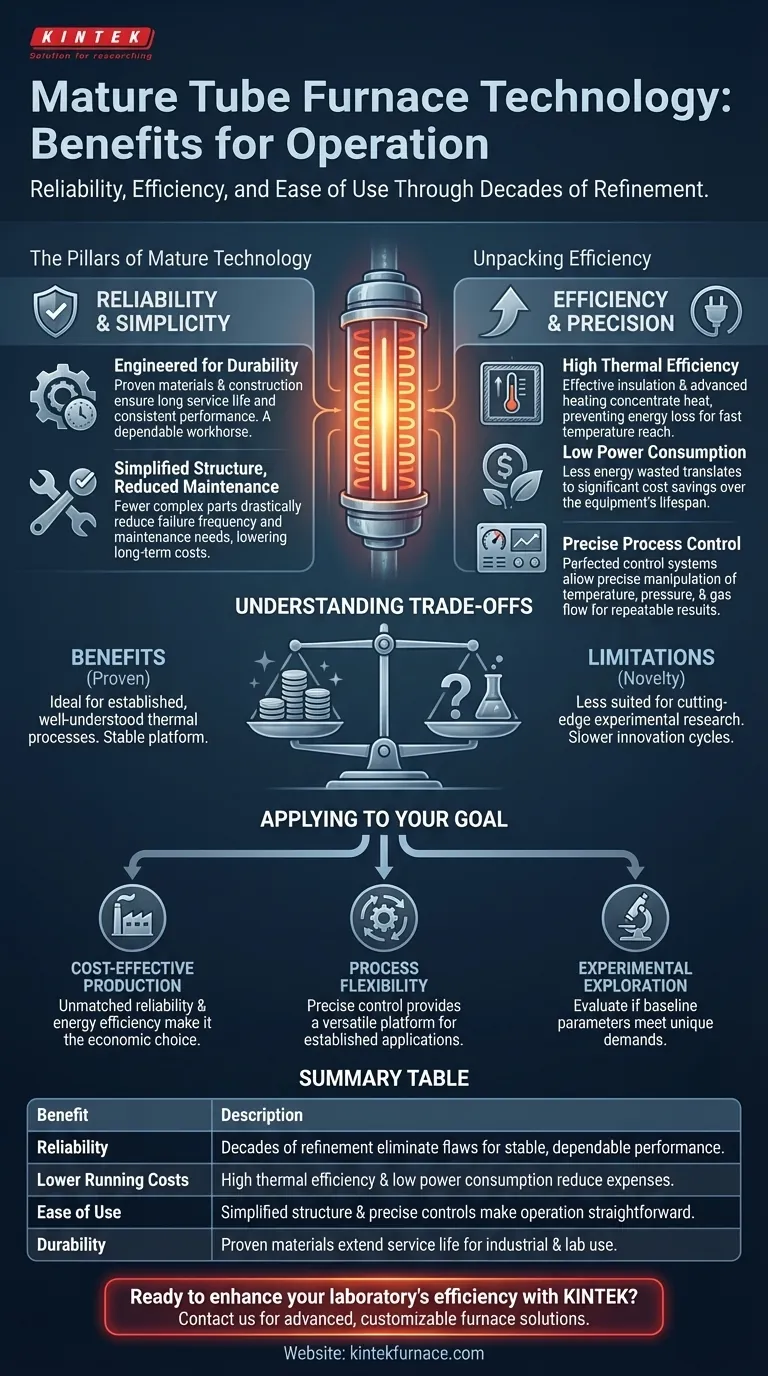

The Pillars of Mature Technology: Reliability and Simplicity

The primary benefit of a mature technology platform is the elimination of unknowns. Years of real-world application have exposed and corrected design flaws, resulting in an exceptionally stable and dependable tool.

Engineered for Durability

A furnace built on proven principles uses materials and construction methods that are known to last. This inherent durability ensures a long service life and consistent performance, making it a reliable workhorse for both industrial production and laboratory research.

Simplified Structure, Reduced Maintenance

Mature designs are often simple by nature. A straightforward structure means there are fewer complex parts that can fail, which drastically reduces the frequency and complexity of maintenance. This simplicity lowers long-term ownership costs and minimizes operational downtime.

Unpacking the Efficiency of a Refined System

Operational efficiency is not just one feature but the result of several optimized systems working together. In a tube furnace, this maturity manifests as significant savings in energy and time.

High Thermal Efficiency

Effective thermal insulation and advanced heating elements are hallmarks of a perfected design. These components work to concentrate heat precisely where it's needed, preventing energy loss to the surrounding environment and ensuring the furnace reaches and maintains target temperatures quickly.

Low Power Consumption

High thermal efficiency directly leads to lower power consumption. Because less energy is wasted, the furnace can perform its heating tasks using less electricity, which translates to significant cost savings over the equipment's lifespan.

Precise Process Control

Decades of refinement have perfected the control systems governing the furnace. Operators can precisely manipulate critical parameters like temperature, pressure, and gas flow rate. This provides the flexibility to support a wide range of applications while ensuring repeatable, accurate results.

Understanding the Trade-offs

While highly beneficial, a mature technology platform has inherent characteristics that are important to understand. Objectivity requires acknowledging these trade-offs.

Less Suited for Cutting-Edge Novelty

A standard tube furnace is optimized for established, well-understood thermal processes. For highly experimental research involving novel heating methods or exotic materials, a more specialized or custom-built apparatus may be required.

Slower Innovation Cycles

The advantage of reliability means that radical design changes are less frequent. While components are continuously improved, the fundamental platform remains stable. This is a contrast to emerging technologies that may offer new features but with less proven long-term performance.

How to Apply This to Your Goal

Your specific objective will determine how you weigh the benefits of a tube furnace's mature design.

- If your primary focus is cost-effective production or routine testing: The furnace's unmatched reliability, low maintenance needs, and energy efficiency make it the ideal economic choice.

- If your primary focus is process flexibility and control: Its ability to precisely manage temperature and atmosphere provides a versatile and dependable platform for a wide range of established applications.

- If your primary focus is exploring highly experimental processes: Acknowledge that a standard furnace is an excellent baseline, but evaluate if its design parameters meet the unique demands of your research.

By understanding these principles, you can confidently leverage the proven advantages of a tube furnace to achieve predictable performance and long-term value.

Summary Table:

| Benefit | Description |

|---|---|

| Reliability | Decades of refinement eliminate design flaws, ensuring stable and dependable performance with minimal failures. |

| Lower Running Costs | High thermal efficiency and low power consumption reduce energy expenses and maintenance needs. |

| Ease of Use | Simplified structure and precise control systems make operation straightforward and adaptable to various applications. |

| Durability | Proven materials and construction methods extend service life, ideal for industrial and lab use. |

Ready to enhance your laboratory's efficiency with a reliable tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements. Contact us today to discuss how our mature technology can deliver cost-effective, dependable performance for your specific goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide