At its core, a muffle furnace achieves uniform and safe heating through a simple but brilliant design principle: separation. It uses an insulated inner chamber, the "muffle," to isolate the material being heated from the actual heating elements. This indirect approach ensures heat is radiated evenly throughout the chamber, preventing direct contact with flames or hot spots, which is the key to its precision and safety.

The defining characteristic of a muffle furnace is its design for indirect heating. By placing heating elements outside a sealed inner chamber, it guarantees that heat is transferred uniformly via radiation, eliminating temperature gradients and protecting the sample from contamination.

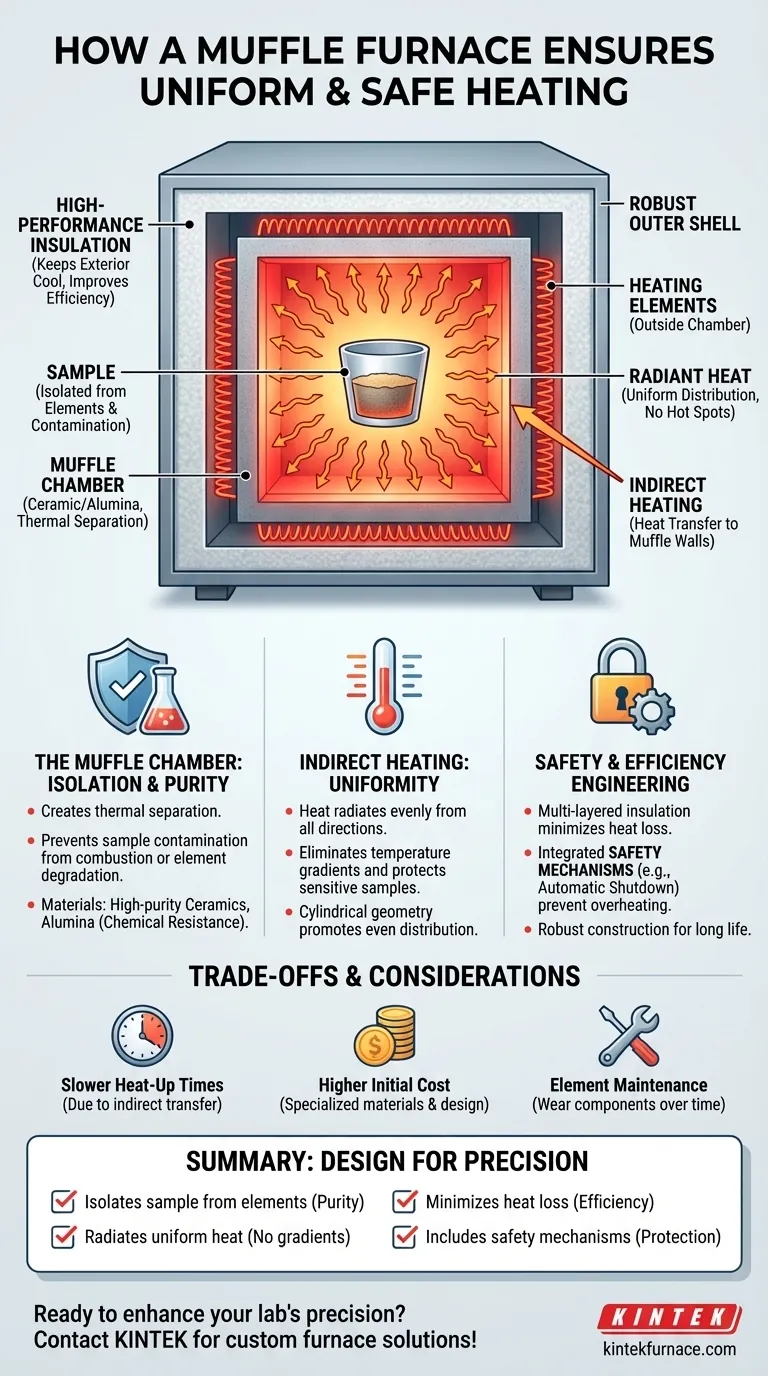

The Core Principle: Indirect Heating and Isolation

A muffle furnace's effectiveness isn't based on a single component, but on how its core parts work together to control the flow of thermal energy.

The Role of the Muffle Chamber

The "muffle" is the heart of the furnace. It is an inner chamber made from highly heat-resistant materials like ceramic or alumina.

This chamber serves several critical functions. First, it creates thermal separation between the heating elements and the sample. This prevents contamination from combustion byproducts and protects the delicate heating elements from any fumes or materials released during the process.

How Indirect Heating Creates Uniformity

The heating elements are placed outside the muffle, heating its walls. These heated walls then radiate thermal energy inward from all directions.

This method is fundamentally different from direct heating, where a flame or element would create intense hot spots. The radiant heat envelops the sample, ensuring a highly uniform temperature throughout the entire chamber and eliminating gradients that could ruin sensitive processes. The geometry of the chamber, often cylindrical, further promotes this even distribution.

Materials Make the Difference

The materials used for the muffle are critical. Refractory materials like alumina and high-purity ceramics are chosen for their ability to withstand extreme temperatures and repeated thermal cycling without cracking or degrading.

These materials also offer excellent chemical resistance, ensuring the chamber itself does not react with or contaminate the materials being processed.

Engineering for Safety and Efficiency

Beyond the muffle itself, the furnace's overall construction is engineered for safe and reliable operation.

High-Performance Insulation

Muffle furnaces are encased in thick layers of high-performance insulation. This serves two purposes.

First, it minimizes heat loss, which makes the furnace more energy-efficient and helps maintain a stable internal temperature. Second, it keeps the exterior of the furnace cool to the touch, a crucial safety feature for operators.

Robust Construction

These furnaces are built to withstand harsh, high-temperature industrial and laboratory environments. Their robust construction ensures a long service life and reliable performance even under continuous use.

Integrated Safety Mechanisms

Modern muffle furnaces include essential safety features, such as automatic shutdown controllers that prevent overheating. This protects both the sample and the furnace itself from damage due to thermal runaway.

Understanding the Trade-offs

While highly effective, the muffle furnace design comes with inherent trade-offs that are important to understand.

Slower Heat-Up Times

Because the heat must first transfer to the muffle chamber walls and then radiate to the sample, the heat-up and cool-down cycles are generally slower than in direct-heat furnaces.

Higher Initial Cost

The specialized materials, multi-layered construction, and sophisticated control systems required for a high-quality muffle furnace often result in a higher initial investment compared to simpler oven designs.

Maintenance of Heating Elements

Although the muffle protects the heating elements from direct exposure to process materials, they are still wear components that will eventually degrade and require replacement over the furnace's life.

Making the Right Choice for Your Application

Evaluating a muffle furnace requires matching its design features to your specific goal.

- If your primary focus is process purity: Scrutinize the muffle material's specifications for chemical inertness and resistance to contamination.

- If your primary focus is temperature uniformity: Look for furnaces with optimized chamber geometry and documented evidence of minimal temperature gradients.

- If your primary focus is operational safety and efficiency: Prioritize models with thick, multi-layered insulation and certified overheating protection systems.

Ultimately, the design of a muffle furnace is a deliberate solution for applications demanding precision, purity, and safety above all else.

Summary Table:

| Design Feature | Function | Benefit |

|---|---|---|

| Muffle Chamber | Isolates sample from heating elements | Prevents contamination and ensures uniform heating |

| Indirect Heating | Radiates heat from chamber walls | Eliminates hot spots and temperature gradients |

| High-Performance Insulation | Minimizes heat loss | Improves efficiency and keeps exterior cool for safety |

| Robust Construction | Withstands high temperatures | Ensures durability and long service life |

| Safety Mechanisms | Includes automatic shutdown | Prevents overheating and protects samples |

Ready to enhance your lab's precision and safety with a custom muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can benefit your specific applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating