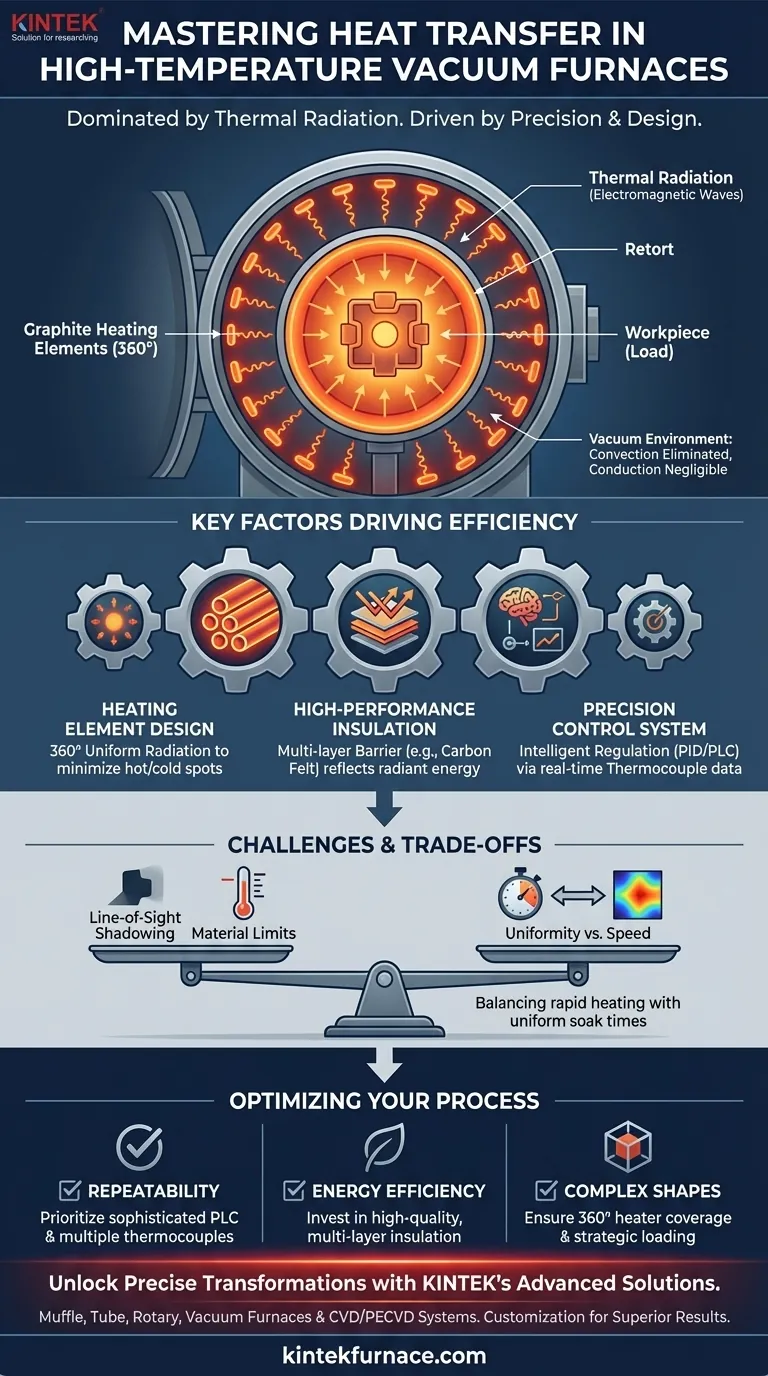

In a high-temperature vacuum furnace, heat transfer occurs almost exclusively through thermal radiation. Because the near-total absence of air molecules makes convection impossible and limits conduction, the furnace's efficiency is determined entirely by its ability to generate, direct, and contain radiant energy.

The core challenge in a vacuum furnace is not simply generating heat, but controlling its path. True efficiency comes from a system where heating elements provide uniform radiation, high-performance insulation contains it, and a precise control system manages the entire process.

The Dominance of Radiation in a Vacuum

In a standard furnace, heat moves through conduction (direct contact), convection (fluid movement, like hot air rising), and radiation. A vacuum fundamentally changes this dynamic.

Why Convection and Conduction are Negligible

A vacuum is an environment with extremely low pressure and very few gas molecules. With no air to circulate, heat transfer via convection is eliminated.

While some conduction occurs where the workpiece touches its supports, this accounts for a tiny fraction of the total heat transfer. The primary mechanism is non-contact.

How Thermal Radiation Works

Every object with a temperature above absolute zero emits thermal energy in the form of electromagnetic waves. Hotter objects radiate more energy than colder ones.

In a vacuum furnace, heating elements (often made of graphite) are heated to a very high temperature. They then radiate this thermal energy in all directions, traveling in a straight line until it is absorbed by a cooler object—the workpiece.

The Two-Step Transfer: Heaters to Workpiece

Often, the heaters are arranged in a circle within the heating chamber. They first radiate heat to a cylindrical container called a retort.

The retort absorbs this energy, heats up, and then radiates its own thermal energy inward, bathing the workpiece (the "load") in a uniform field of heat.

Key Factors Driving Furnace Efficiency

Achieving a fast, uniform, and repeatable heating process depends on the sophisticated interplay of several key components.

Heating Element Design and Placement

The effectiveness of the heating elements is paramount. For maximum uniformity, they are often designed as circular tubes and distributed evenly at 360 degrees around the heating chamber.

This arrangement helps ensure that the workpiece receives radiant energy from all sides, minimizing hot spots and cold spots.

High-Performance Thermal Insulation

Containing the immense heat generated is critical for both efficiency and safety. Modern furnaces use advanced, multi-layer insulation systems.

Materials like high-grade carbon felt and flexible graphite paper are used to create a lightweight but highly effective thermal barrier. This insulation reflects radiant energy back toward the workpiece, minimizing energy loss to the outside environment.

Managing the Thermal Field

Even with uniform heaters, a temperature gradient (a difference in temperature across a space) will exist. The goal is to manage this gradient so that the entire workpiece reaches the target temperature as uniformly as possible.

Studying this "thermal field" is a key aspect of furnace design, ensuring that complex parts are heated evenly.

Understanding the Trade-offs and Challenges

Designing and operating a vacuum furnace involves balancing competing priorities.

The "Line-of-Sight" Problem

Thermal radiation travels in straight lines. This means any part of the workpiece that is "shadowed" by another part or by the support fixtures will not heat as quickly.

This is a fundamental challenge that influences how parts must be loaded into the furnace to ensure all surfaces are adequately exposed to the radiant heat source.

Uniformity vs. Speed

Heating a workpiece too quickly can create significant temperature differences between its surface and its core. Achieving excellent thermal uniformity often requires slower, more controlled heating ramps to allow the heat to "soak" into the material.

Material and Structural Limits

The choice of graphite for heaters and carbon felt for insulation is deliberate; these materials can withstand extreme temperatures in a vacuum. However, they have a finite lifespan and define the furnace's maximum operating temperature and maintenance schedule.

The Critical Role of the Control System

The "brawn" of the heating elements is useless without the "brain" of a sophisticated control system.

Precision Measurement with Thermocouples

Thermocouples are sensors placed inside the furnace to measure temperature in real-time. Their accurate readings are the foundation of any controlled heating process.

Intelligent Regulation (PID/PLC)

This data is fed to a temperature controller, which can range from a PID (Proportional-Integral-Derivative) programmer to a fully automatic PLC (Programmable Logic Controller).

This controller constantly compares the actual temperature to the desired temperature profile. It then adjusts the power supplied to the heating elements to precisely follow the programmed cycle of heating, holding at temperature (soaking), and cooling, which is essential for processes like annealing, tempering, and sintering.

Optimizing Your Vacuum Furnace Process

Achieving consistent, high-quality results depends on aligning the furnace's design and operation with your specific metallurgical goals.

- If your primary focus is process repeatability: Prioritize a furnace with a sophisticated PLC control system and multiple, well-placed thermocouples to guarantee identical thermal profiles run after run.

- If your primary focus is maximum energy efficiency: Invest in a furnace with high-quality, multi-layer insulation (like carbon felt and graphite paper) to minimize heat loss and reduce power consumption.

- If your primary focus is treating complex shapes: Look for designs with 360-degree heater coverage and carefully plan your loading configuration to minimize radiative "shadowing."

Ultimately, mastering heat transfer in a vacuum furnace is about controlling the flow of pure energy to achieve precise material transformations.

Summary Table:

| Factor | Influence on Efficiency |

|---|---|

| Heating Element Design | Ensures uniform radiation for even heating |

| Thermal Insulation | Minimizes energy loss by reflecting heat |

| Control System | Provides precise temperature regulation |

| Material Selection | Determines durability and temperature limits |

| Loading Configuration | Reduces shadowing for better heat exposure |

Unlock precise material transformations with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures your unique experimental requirements are met for superior efficiency and repeatability. Contact us today to optimize your vacuum furnace process!

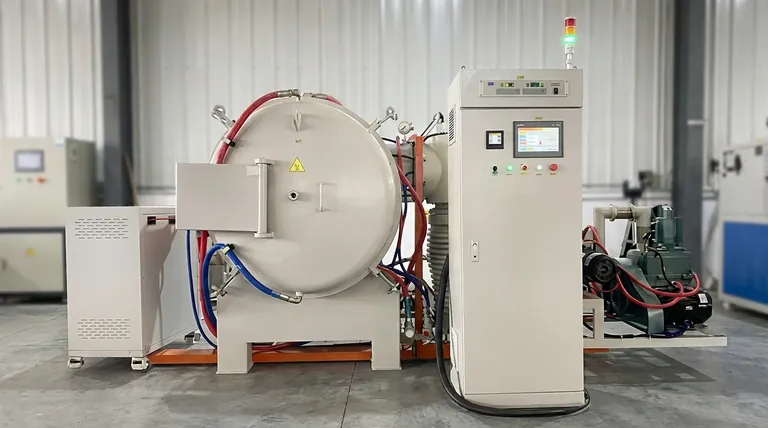

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering