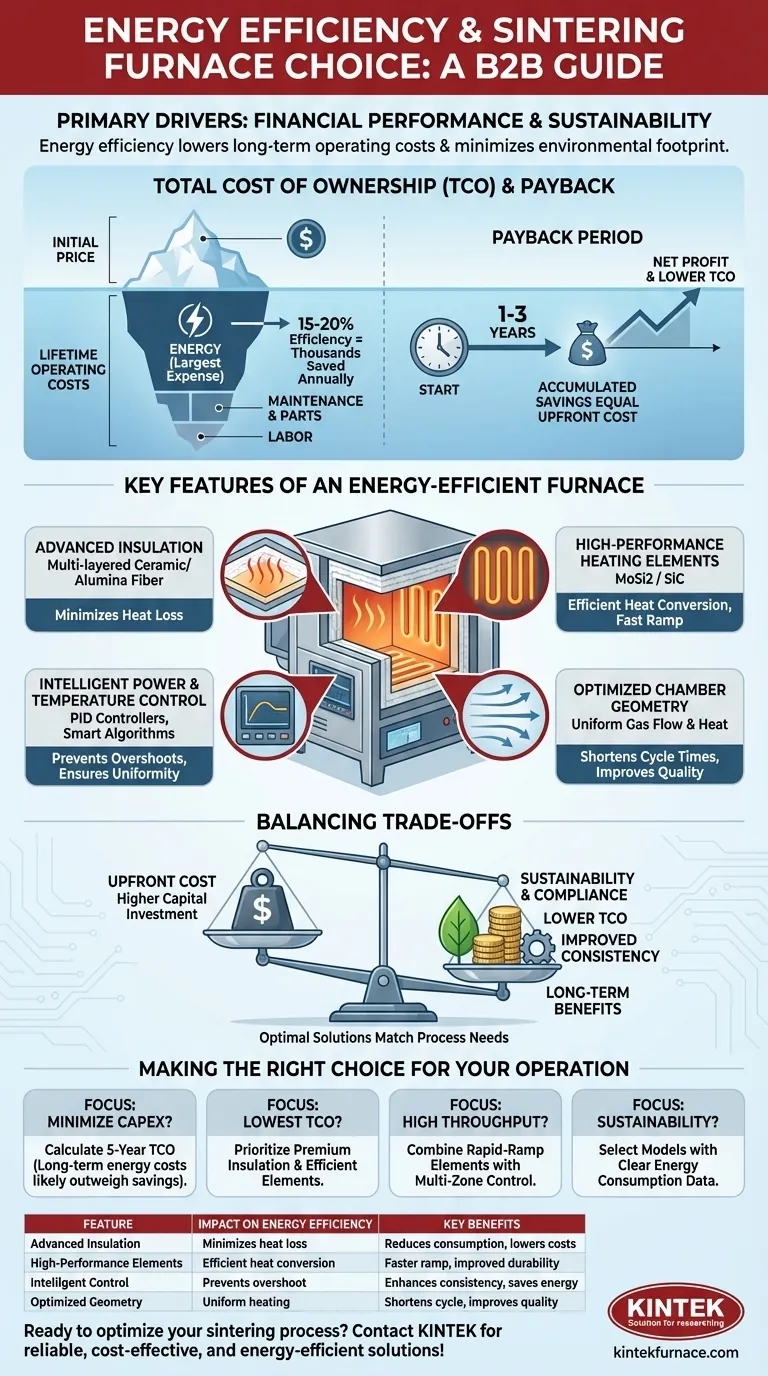

In short, energy efficiency is a primary driver of financial performance and sustainability when selecting a sintering furnace. It directly impacts your long-term operating budget by lowering electricity and gas consumption, which are often the largest expenses after the initial purchase. This reduction in energy use also minimizes the furnace's environmental footprint, aligning with modern corporate and regulatory standards.

The decision to invest in an energy-efficient sintering furnace is fundamentally a strategic choice about its Total Cost of Ownership (TCO). While the initial price may be higher, the substantial and recurring savings on energy often deliver a rapid return on investment and a lower overall cost across the equipment's lifecycle.

Beyond the Sticker Price: The Total Cost of Ownership

When evaluating a sintering furnace, the purchase price is only one part of the financial equation. A true assessment requires calculating the Total Cost of Ownership (TCO).

What Defines TCO for a Furnace?

TCO encompasses the initial purchase price plus all costs incurred during the furnace's operational life. This includes energy consumption, routine maintenance, replacement parts (like heating elements and insulation), and labor.

How Energy Dominates Operating Costs

For high-temperature equipment like a sintering furnace, energy is the single largest operational expense. A furnace that is 15-20% more efficient can translate into thousands of dollars in savings annually, quickly eclipsing any initial price difference.

Calculating the Payback Period

The payback period is the time it takes for the accumulated energy savings to equal the higher upfront cost of an efficient model. For many industrial operations running multiple cycles per day, this period can be surprisingly short, often falling within 1 to 3 years.

Key Features of an Energy-Efficient Furnace

Energy efficiency isn't a single feature but the result of a well-engineered system. Several key technologies work together to minimize heat loss and optimize energy use.

Advanced Insulation Packages

Modern furnaces use multi-layered, lightweight ceramic and alumina fiber insulation. These materials have extremely low thermal conductivity, meaning they are far better at keeping heat inside the chamber compared to older, heavier firebricks. This is the most critical factor in preventing wasted energy.

High-Performance Heating Elements

Heating elements made from materials like Molybdenum Disilicide (MoSi2) or Silicon Carbide (SiC) are designed for efficiency at very high temperatures. They convert electricity to heat with minimal loss and can often ramp to temperature more quickly, shortening cycle times and overall energy use.

Intelligent Power and Temperature Control

Modern PID (Proportional-Integral-Derivative) controllers with smart tuning algorithms prevent temperature overshoots. Overshooting the setpoint temperature is a significant source of wasted energy and can also negatively impact part quality. Multi-zone control further refines this by ensuring uniform heat, preventing colder spots that might require longer soak times.

Optimized Chamber Geometry

A well-designed furnace chamber ensures uniform gas flow and heat distribution. This means there are no significant cold spots, allowing for shorter cycle times and ensuring every part in the batch receives the same thermal treatment without wasting energy to "catch up" certain areas.

Understanding the Trade-offs

Choosing an energy-efficient model involves balancing initial cost against long-term benefits. There are no perfect solutions, only optimal ones for a specific application.

The Upfront Cost Hurdle

The most significant trade-off is the higher initial capital investment. Furnaces built with advanced insulation, premium heating elements, and sophisticated controls cost more to manufacture and therefore have a higher purchase price.

Potential for Specialized Maintenance

While generally reliable, some high-performance components may require specific maintenance procedures or have different replacement lifecycles than traditional parts. It is crucial to understand the maintenance schedule and cost of spares for any model you consider.

Matching Efficiency to Your Process

A furnace optimized for a long, high-temperature cycle may not be the most efficient choice for a process involving many short, lower-temperature cycles. The efficiency benefits are greatest when the furnace design is closely matched to its primary operational use case.

Making the Right Choice for Your Operation

To select the right furnace, you must first define your primary business objective.

- If your primary focus is minimizing upfront capital expenditure: A standard furnace may seem appealing, but you must rigorously calculate the projected 5-year TCO. The long-term energy costs will almost certainly outweigh the initial savings.

- If your primary focus is the lowest Total Cost of Ownership: Prioritize a furnace with a premium insulation package and efficient heating elements. These features deliver the most significant and recurring energy savings, providing the strongest return on investment.

- If your primary focus is high throughput and process consistency: Look for a furnace that combines rapid-ramp heating elements with multi-zone temperature control to ensure uniformity and reduce cycle times.

- If your primary focus is sustainability and compliance: Select a model where the manufacturer can provide clear data on energy consumption. This documentation is critical for corporate sustainability reports and meeting environmental regulations.

Ultimately, choosing a furnace based on its energy efficiency is an investment in the long-term financial health and sustainability of your operation.

Summary Table:

| Feature | Impact on Energy Efficiency | Key Benefits |

|---|---|---|

| Advanced Insulation | Minimizes heat loss | Reduces energy consumption, lowers operating costs |

| High-Performance Heating Elements | Efficient heat conversion | Faster ramp times, improved durability |

| Intelligent Control Systems | Prevents temperature overshoot | Enhances process consistency, saves energy |

| Optimized Chamber Geometry | Ensures uniform heating | Shortens cycle times, improves part quality |

Ready to optimize your sintering process with an energy-efficient furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental requirements. Lower your total cost of ownership and enhance sustainability—contact us today to discuss how we can deliver reliable, cost-effective solutions for your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency