In metallurgy, the primary benefit of an atmosphere furnace is its ability to create a precisely controlled chemical environment during heat treatment. This control prevents destructive reactions like oxidation and allows for targeted surface modifications, resulting in materials with superior strength, purity, and specific performance characteristics that are impossible to achieve in open-air heating.

The core challenge in high-temperature metallurgy is that ambient air chemically attacks the metal, causing scaling and degradation. An atmosphere furnace solves this by replacing the air with a specific, controlled gas mixture, giving you complete command over the material's final properties.

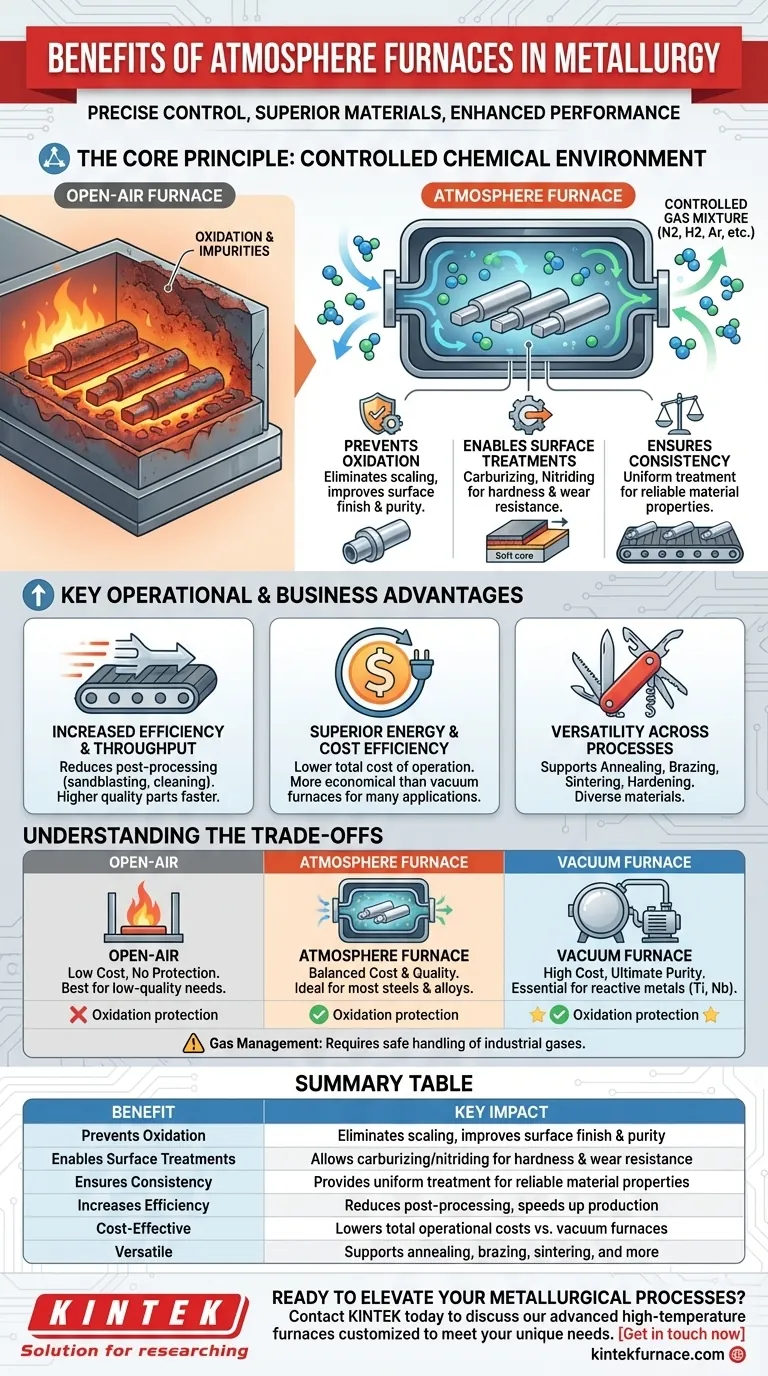

The Core Principle: Gaining Control Over the Chemical Environment

Heating metal in the presence of oxygen, even the 21% found in normal air, fundamentally alters its surface and structure. An atmosphere furnace works by purging the heating chamber of air and replacing it with a neutral, reactive, or reducing gas.

Preventing Oxidation and Impurities

The most common reason to use an atmosphere furnace is to prevent oxidation. When hot metal is exposed to oxygen, it forms a brittle layer of scale on the surface.

This oxidation leads to material loss, poor surface finish, and compromised structural integrity. By using an inert gas like nitrogen or argon, the furnace creates an environment free of oxygen, ensuring the metal's surface remains clean and unaltered.

This process directly results in improved product quality with fewer impurities and avoids unwanted chemical reactions that can weaken the final part.

Enabling Targeted Surface Treatments

Beyond preventing unwanted reactions, atmosphere furnaces can introduce active gases to deliberately change the material's surface properties.

Processes like carburizing (adding carbon) or nitriding (adding nitrogen) use the controlled atmosphere to diffuse elements into the surface of steel parts, creating an extremely hard, wear-resistant outer case while maintaining a softer, tougher core.

Ensuring Material Integrity and Consistency

The precise control over both temperature and atmosphere ensures that every part in a batch receives the exact same treatment. This uniformity is critical for applications where material properties must be predictable and consistent.

By eliminating the variables of open-air heating, you achieve enhanced material integrity and reliable performance across your entire production run.

Key Operational and Business Advantages

The technical benefits of atmospheric control translate directly into significant operational and business advantages, making these furnaces a cornerstone of modern manufacturing.

Increased Efficiency and Throughput

Because parts emerge from the furnace clean and free of scale, the need for costly and time-consuming secondary operations like sandblasting, chemical cleaning, or machining is drastically reduced or eliminated.

This increases overall process efficiency and production throughput, allowing you to produce higher quality parts faster.

Superior Energy and Cost Efficiency

Modern atmosphere furnaces are designed for high energy efficiency. Furthermore, by preventing material loss from scaling and reducing post-processing needs, they deliver a lower total cost of operation.

While the initial investment may be higher than a simple air furnace, they are often a more economical choice than vacuum furnaces for many common applications.

Versatility Across Processes

These furnaces are not limited to a single task. They are highly versatile and can be configured for a wide range of thermal processes, including annealing, brazing, sintering, and hardening.

This flexibility allows them to process parts of various shapes and sizes made from diverse materials like metals, alloys, and ceramics.

Understanding the Trade-offs

While powerful, an atmosphere furnace is not the universal solution for all heat treatment. Understanding its position relative to other technologies is key to making an informed decision.

Atmosphere vs. Open-Air Furnaces

The choice here is a direct trade-off between cost and quality. Open-air furnaces are simpler and cheaper but offer no protection from oxidation. For any application where surface finish, purity, or specific surface properties are important, an atmosphere furnace is the superior choice.

Atmosphere vs. Vacuum Furnaces

A vacuum furnace represents the ultimate level of environmental control by removing virtually all molecules from the chamber. They are essential for highly reactive metals like titanium or for applications demanding the absolute highest purity.

However, vacuum furnaces come with a significantly higher cost and often have longer cycle times. An atmosphere furnace provides a more cost-effective solution for the vast majority of metals, including most steels and alloys.

The Complexity of Gas Management

Operating an atmosphere furnace requires a system for storing, mixing, and safely handling industrial gases. This adds a layer of operational complexity and safety protocol compared to simpler furnace types.

Making the Right Choice for Your Goal

Selecting the correct thermal processing technology depends entirely on your material, your desired outcome, and your operational constraints.

- If your primary focus is high-volume steel treatment: An atmosphere furnace is the industry standard for processes like annealing and carburizing, offering an ideal balance of quality, speed, and cost.

- If your primary focus is research or processing sensitive, non-reactive materials: A batch or tube-style atmosphere furnace provides the precision and control needed for materials development and specialized production.

- If your primary focus is processing highly reactive metals like titanium or niobium: A vacuum furnace is the necessary choice to prevent any contamination and achieve the required material purity.

Ultimately, mastering the thermal environment is fundamental to mastering the properties of the final material.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Prevents Oxidation | Eliminates scaling, improves surface finish and purity |

| Enables Surface Treatments | Allows carburizing/nitriding for hardness and wear resistance |

| Ensures Consistency | Provides uniform treatment for reliable material properties |

| Increases Efficiency | Reduces post-processing, speeds up production |

| Cost-Effective | Lowers total operational costs vs. vacuum furnaces |

| Versatile | Supports annealing, brazing, sintering, and more |

Ready to elevate your metallurgical processes with tailored furnace solutions? Contact KINTEK today to discuss how our advanced high-temperature furnaces—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—can be customized to meet your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we deliver precise control and efficiency for industries like steel treatment and materials research. Get in touch now to optimize your heat treatment and achieve superior results!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity