At its core, a tube furnace is a high-temperature heating device that processes materials inside a cylindrical work tube. The furnace generates heat using external heating elements, which radiates inward to uniformly heat the sample contained within the tube. This design isolates the sample, allowing for precise control over both temperature and the atmospheric environment.

A tube furnace’s primary function is to provide highly uniform and stable heating in a controlled environment. It achieves this by transferring heat from an external source to a sample held inside a separate, often sealed, work tube, making it ideal for sensitive material processing, synthesis, and analysis.

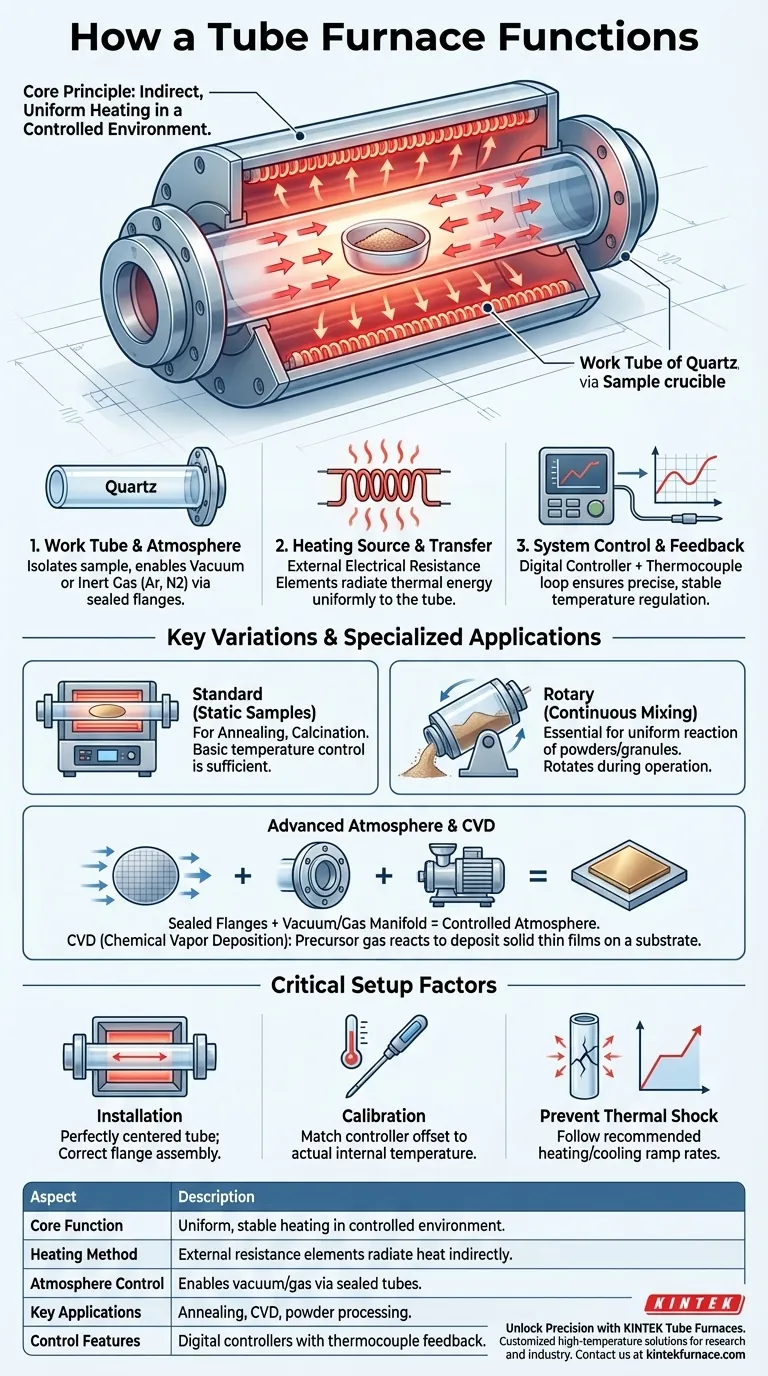

How a Tube Furnace Achieves Precise Heating

The effectiveness of a tube furnace comes from its simple but robust design, which separates the heat source from the material being processed. This separation is the key to its precision and versatility.

The Central Role of the Work Tube

The work tube is the heart of the furnace. It's a cylindrical tube, typically made of quartz, alumina (corundum), or a metal alloy, into which samples are placed.

This tube serves two critical purposes: it contains the sample and enables atmosphere control. By sealing the ends with specialized flanges, you can create a vacuum or introduce inert gases (like argon or nitrogen) or reactive gases.

The Heating Source and Transfer

Most modern tube furnaces use electrical resistance heating elements that surround the work tube. When current is passed through them, they heat up and radiate thermal energy.

This heat is transferred uniformly to the outer surface of the work tube and then conducted inward to the sample. This indirect heating method prevents contamination and ensures the sample is heated evenly from all sides. Some industrial-scale furnaces may use fuel combustion, but electrical resistance is more common for laboratory settings.

System Control and Uniformity

A digital controller is used to set the target temperature and heating rate. A thermocouple placed near the work tube measures the real-time temperature, creating a feedback loop that allows the controller to precisely regulate power to the heating elements.

This automated control maintains a stable and uniform thermal zone in the center of the furnace, which is critical for repeatable experiments and processes.

Key Variations for Specific Applications

While the basic principle is the same, tube furnaces are adapted for highly specialized tasks. The configuration you need depends entirely on your process goals.

Standard vs. Rotary Furnaces

A standard, or stationary, tube furnace is used for processing static samples, such as annealing a wafer or calcining a powder in a crucible.

A rotary tube furnace, in contrast, features a tube that is mounted at an angle and rotates during operation. This is essential for continuous processing or when materials, like powders or granules, need to be constantly mixed to ensure every particle is exposed to the heat and atmosphere.

Vacuum and Atmosphere Control

The ability to control the atmosphere is one of the most powerful features of a tube furnace. By using stainless steel sealing flanges with airtight O-rings, the work tube becomes a sealed chamber.

A vacuum pump can then be used to evacuate the air before backfilling with a specific gas. This is crucial for working with materials that would oxidize or react undesirably with air at high temperatures.

Chemical Vapor Deposition (CVD)

A CVD furnace is a specialized type of tube furnace designed for creating thin films. In this process, precursor gases are flowed through the heated tube.

The high temperature causes the gases to react and deposit a solid material onto a substrate (like a silicon wafer) placed inside the tube. This requires precise control over temperature, pressure, and gas flow rates.

Understanding the Critical Setup Factors

A tube furnace's performance is highly dependent on proper setup and maintenance. Mistakes in these areas are the most common source of problems.

Correct Installation is Non-Negotiable

The work tube must be installed perfectly centered within the furnace, ensuring it does not touch the heating elements, which could cause it to crack.

When installing sealing flanges, the components must be assembled in the correct order and the screws tightened evenly. An improperly sealed flange will leak, destroying any attempt at atmosphere control.

The Importance of Calibration

The temperature displayed on the controller is not always the exact temperature inside the tube where your sample sits. There is inevitably a slight difference.

For precise work, the furnace must be calibrated. This involves placing a calibrated, high-precision thermometer inside the work tube at the sample's position and adjusting the furnace controller's offset to match the true reading.

Preventing Thermal Shock

Work tubes, especially those made of quartz or alumina, are susceptible to thermal shock. Heating or cooling them too rapidly can cause them to crack. Always follow the manufacturer's recommended ramp rates to ensure the longevity of your equipment.

Making the Right Choice for Your Process

Your choice of furnace configuration must be driven by your end goal.

- If your primary focus is basic heat treatment or annealing: A standard furnace with basic temperature control is sufficient.

- If your primary focus is processing air-sensitive materials: You must use a furnace system equipped with sealing flanges and a gas/vacuum manifold.

- If your primary focus is ensuring uniform reaction of powders: A rotary tube furnace is the only way to guarantee consistent mixing and exposure.

- If your primary focus is depositing high-quality thin films: A dedicated CVD system with mass flow controllers and advanced pressure control is required.

By understanding these core principles and configurations, you can effectively leverage a tube furnace for precise and repeatable thermal processing.

Summary Table:

| Aspect | Description |

|---|---|

| Core Function | Provides uniform, stable heating in a controlled environment for material processing. |

| Heating Method | Uses external electrical resistance elements to radiate heat indirectly to samples. |

| Atmosphere Control | Enables vacuum or gas environments via sealed work tubes for sensitive applications. |

| Key Applications | Annealing, calcination, CVD thin film deposition, and powder processing. |

| Control Features | Digital controllers with thermocouples for precise temperature and ramp rate regulation. |

Unlock Precision in Your Lab with KINTEK Tube Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need uniform heating, atmosphere control, or specialized setups for synthesis and analysis, our tube furnaces deliver reliability and accuracy.

Contact us today to discuss how we can tailor a solution for your specific needs and enhance your thermal processing efficiency. Get in touch now!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents