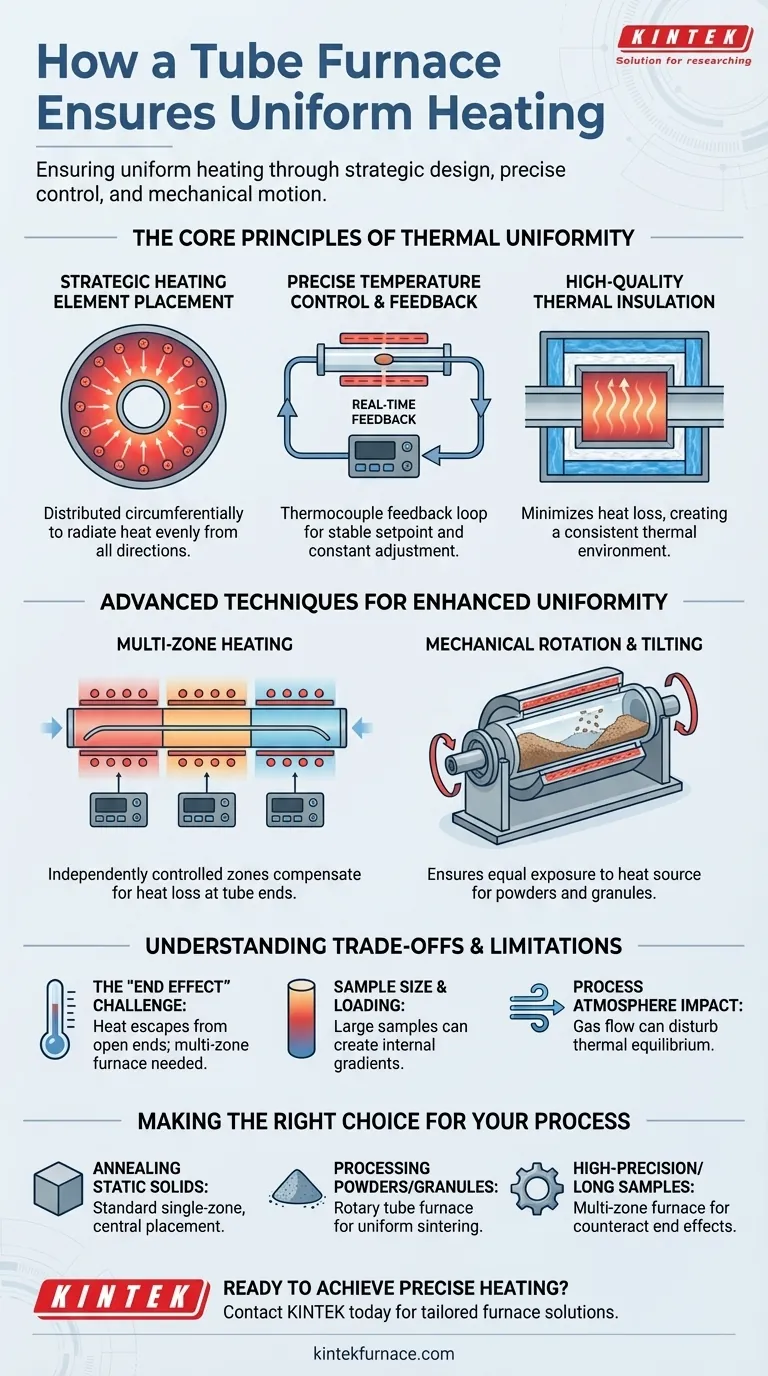

To ensure uniform heating, a tube furnace combines three core principles: strategic design, precise control, and in some cases, mechanical motion. The heating elements are arranged cylindrically around the work tube to radiate heat evenly, while a thermocouple feedback loop constantly adjusts power to maintain a stable setpoint. High-quality thermal insulation minimizes heat loss, creating a consistent thermal environment essential for reliable material processing.

The challenge of uniform heating is not solved by a single feature, but by an integrated system. The furnace's cylindrical geometry, intelligent temperature feedback, and a well-insulated chamber work in concert to create a stable and homogenous thermal zone.

The Core Principles of Thermal Uniformity

A tube furnace's ability to deliver consistent temperature is rooted in its fundamental design. Each component plays a specific role in managing the flow and distribution of thermal energy.

Strategic Placement of Heating Elements

The heating elements, typically resistance wires or silicon carbon rods, are not placed randomly. They are distributed circumferentially around the exterior of the furnace tube.

This arrangement ensures that heat radiates inward from all directions, minimizing hot or cold spots along the tube's surface and promoting even heat transfer to the sample inside.

The Role of Cylindrical Geometry

The cylindrical shape of the work tube is inherently advantageous for thermal uniformity. It creates a consistent distance from the heating elements to the central axis of the tube.

This geometric consistency ensures that heat traveling via radiation and convection is distributed symmetrically throughout the internal volume.

Precise Temperature Control and Feedback

A tube furnace operates as a closed-loop system. A thermocouple, a highly sensitive temperature sensor, is placed near the heating elements or the sample.

This thermocouple provides real-time temperature data to the furnace controller. The controller constantly compares this reading to the desired setpoint and adjusts the electrical power sent to the heating elements, preventing temperature overshoot or undershoot.

High-Quality Thermal Insulation

Effective insulation is critical for stability. The heating chamber is encased in layers of advanced ceramic fiber or brick insulation.

This material prevents heat from escaping to the surrounding environment. By containing the thermal energy, the insulation helps the furnace maintain a stable temperature with minimal power fluctuation, which directly contributes to uniformity.

Advanced Techniques for Enhanced Uniformity

For applications demanding the highest level of precision, standard designs are augmented with more sophisticated features.

Multi-Zone Heating

Many advanced furnaces divide the total heated length into multiple, independently controlled heating zones. Each zone has its own heating elements and thermocouple.

This allows the controller to compensate for heat loss that naturally occurs at the ends of the tube, creating a much longer and more uniform flat temperature profile. It can also be used to create intentional temperature gradients for complex processes.

Mechanical Rotation and Tilting

For processing powders, granules, or viscous liquids, a rotary tube furnace is used. The entire work tube is slowly rotated by a motor.

This constant tumbling ensures that every particle of the material is exposed to the heat source equally, preventing local overheating, promoting consistent chemical reactions, and ensuring uniform sintering. Tilting functionality can also be used to control the flow and residence time of material through the tube.

Understanding the Trade-offs and Limitations

While highly effective, achieving perfect uniformity requires understanding the inherent challenges of the system.

The "End Effect" Challenge

Heat will always escape more readily from the open ends of the furnace tube. In a simple, single-zone furnace, this creates a temperature profile that is hottest in the center and cooler toward the ends.

For this reason, a sample must be placed directly in the furnace's "hot zone" center. For longer samples or processes needing a wider uniform area, a multi-zone furnace is the only effective solution.

Sample Size and Loading

The size, shape, and thermal conductivity of the sample itself can impact uniformity. A very large sample can create its own internal temperature gradients and may obstruct the even flow of heat within the tube.

Properly positioning the sample in the center of the uniform zone is critical for achieving repeatable results.

Process Atmosphere Impact

Many processes require a specific gas (e.g., nitrogen, argon) to flow through the tube. This gas flow, a form of forced convection, can carry heat with it.

A high flow rate can disturb the thermal equilibrium, potentially creating a temperature gradient along the direction of flow. Controlling the gas flow rate is therefore another important parameter for maintaining uniformity.

Making the Right Choice for Your Process

Understanding these mechanisms empowers you to select the right equipment for your specific goal.

- If your primary focus is annealing a small, static solid: A standard single-zone furnace is often sufficient, provided the sample is placed carefully in the central hot zone.

- If your primary focus is processing powders or granules: A rotary tube furnace is essential to prevent uneven sintering and ensure consistent material properties.

- If your primary focus is high-precision results or processing long samples (e.g., CVD): A multi-zone furnace is non-negotiable to counteract end effects and guarantee a highly uniform temperature profile.

By matching the furnace's capabilities to your application's demands, you gain direct control over the quality and repeatability of your results.

Summary Table:

| Principle | Key Feature | Benefit |

|---|---|---|

| Strategic Design | Cylindrical heating element placement | Even heat radiation from all directions |

| Precise Control | Thermocouple feedback loop | Stable temperature maintenance |

| Thermal Insulation | High-quality ceramic insulation | Minimized heat loss and stable environment |

| Advanced Techniques | Multi-zone heating and mechanical rotation | Enhanced uniformity for powders and long samples |

Ready to achieve precise and uniform heating in your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your material processing and ensure reliable results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability