At its core, a muffle furnace supports controlled atmosphere operations by using its inner chamber—the "muffle"—to create a physical barrier between the workload and the furnace's heating elements. This fundamental separation allows a sealed, controlled environment to be established around the sample, free from the contamination and reactivity of the heating elements and the outside air.

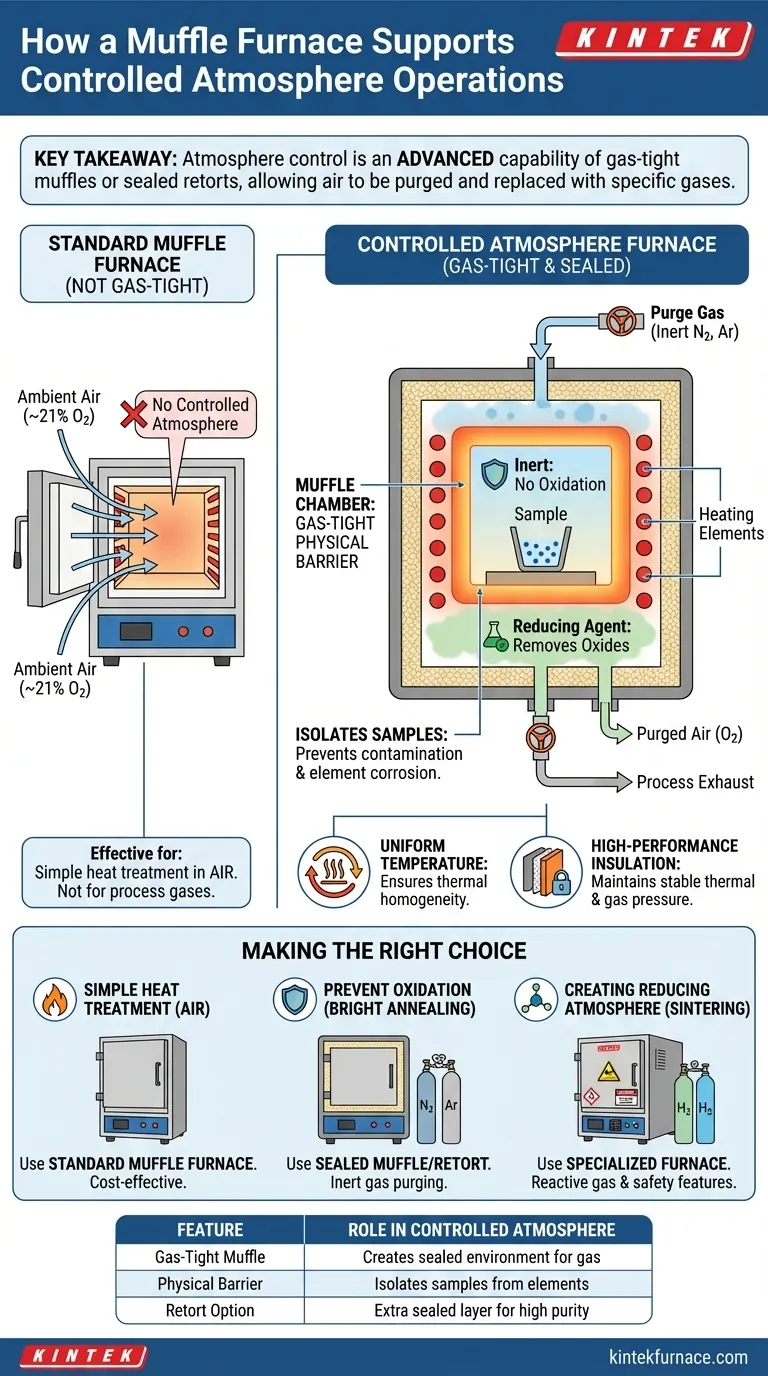

The key takeaway is that atmosphere control in a muffle furnace is not an inherent feature of all models. It is an advanced capability enabled by a gas-tight muffle or an internal sealed retort, which allows ambient air to be purged and replaced with a specific, pure gas environment.

The Central Role of the Muffle Chamber

The design of the muffle is the foundation upon which all atmosphere control is built. It serves several critical functions simultaneously.

A Physical Barrier Against Contamination

The muffle is an isolated chamber made of a non-reactive material, typically a durable ceramic like alumina. This isolates the samples from the heating elements.

This separation prevents the process gas (e.g., nitrogen, argon, or hydrogen) from corroding the heating elements and, conversely, prevents any particles shed by the elements from contaminating the samples.

Creating a Sealable Volume

For true atmosphere control, the muffle chamber must be designed to be gas-tight. This allows for the two most critical steps in the process.

First, the ambient air (which is ~21% reactive oxygen) can be removed, typically by purging with an inert gas. Second, the desired process gas or gas mixture can be introduced and maintained at a specific pressure and flow rate.

Enabling Specific Gas Atmospheres

Once sealed and purged, the chamber can be filled with gases like nitrogen or argon to create an inert atmosphere that prevents oxidation.

For other processes, a reactive gas like hydrogen can be used to create a "reducing" atmosphere, which actively removes oxides from a material's surface.

Supporting Features for a Stable Process

While the sealed muffle is the primary component, other furnace features are essential for making the controlled atmosphere effective and repeatable.

Uniform Temperature Distribution

A controlled atmosphere is only useful if the temperature is also precisely controlled. The geometry and material of the muffle are designed to absorb heat from the elements and radiate it evenly throughout the chamber.

This thermal homogeneity is critical for sensitive processes like annealing, tempering, and sintering, ensuring the entire part receives the same treatment.

High-Performance Insulation

Advanced insulation does more than just save energy. By minimizing heat loss, it creates a highly stable thermal environment inside the furnace.

This stability makes it easier to maintain both a consistent temperature and a consistent gas pressure, which are vital for achieving repeatable, high-quality results.

Understanding the Trade-offs: Standard vs. Atmosphere Furnaces

It is a common and costly mistake to assume any muffle furnace can handle controlled atmospheres. The distinction between models is critical.

Not All Muffle Furnaces Are Equal

A standard, entry-level muffle furnace provides thermal separation but is not gas-tight. It is designed for operation in air only. Attempting to run process gases through it will be ineffective and potentially hazardous.

The Role of the Retort

For the highest-purity applications, many atmosphere furnaces use a sealed vessel called a retort that is placed inside the muffle chamber.

This retort, often made of a metal alloy or quartz, acts as a perfectly sealed container for the workload and process gas, providing an extra layer of control and purity.

Safety and Material Compatibility

Introducing process gases, especially flammable ones like hydrogen, requires a furnace specifically designed for that purpose. These systems include safety interlocks, leak-tight gas fittings, and materials that will not degrade when exposed to the specific gas at high temperatures.

Making the Right Choice for Your Application

To select the correct equipment, you must first define your process goal.

- If your primary focus is simple heat treatment in air: A standard muffle furnace is perfectly sufficient and cost-effective.

- If your primary focus is preventing oxidation (e.g., bright annealing): You need a furnace with a sealed muffle or retort, complete with gas inlet/outlet ports for purging with inert gases like nitrogen or argon.

- If your primary focus is creating a reducing atmosphere (e.g., sintering): You must use a specialized furnace rated for reactive gases like hydrogen, which includes mandatory safety and material compatibility features.

Ultimately, understanding the distinction between a basic muffle and a truly atmosphere-capable system is the key to achieving a successful thermal process.

Summary Table:

| Feature | Role in Controlled Atmosphere |

|---|---|

| Gas-Tight Muffle | Creates a sealed environment for purging air and introducing process gases like nitrogen or hydrogen |

| Physical Barrier | Isolates samples from heating elements to prevent contamination and corrosion |

| Uniform Temperature | Ensures even heat distribution for consistent results in processes like annealing |

| High-Performance Insulation | Maintains stable thermal and gas pressure conditions for repeatability |

| Retort Option | Provides an extra sealed layer for high-purity applications with reactive gases |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether for inert atmospheres, reducing environments, or specialized safety features. Don't compromise on purity and precision—contact us today to discuss how our tailored solutions can optimize your thermal processes and drive success!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process