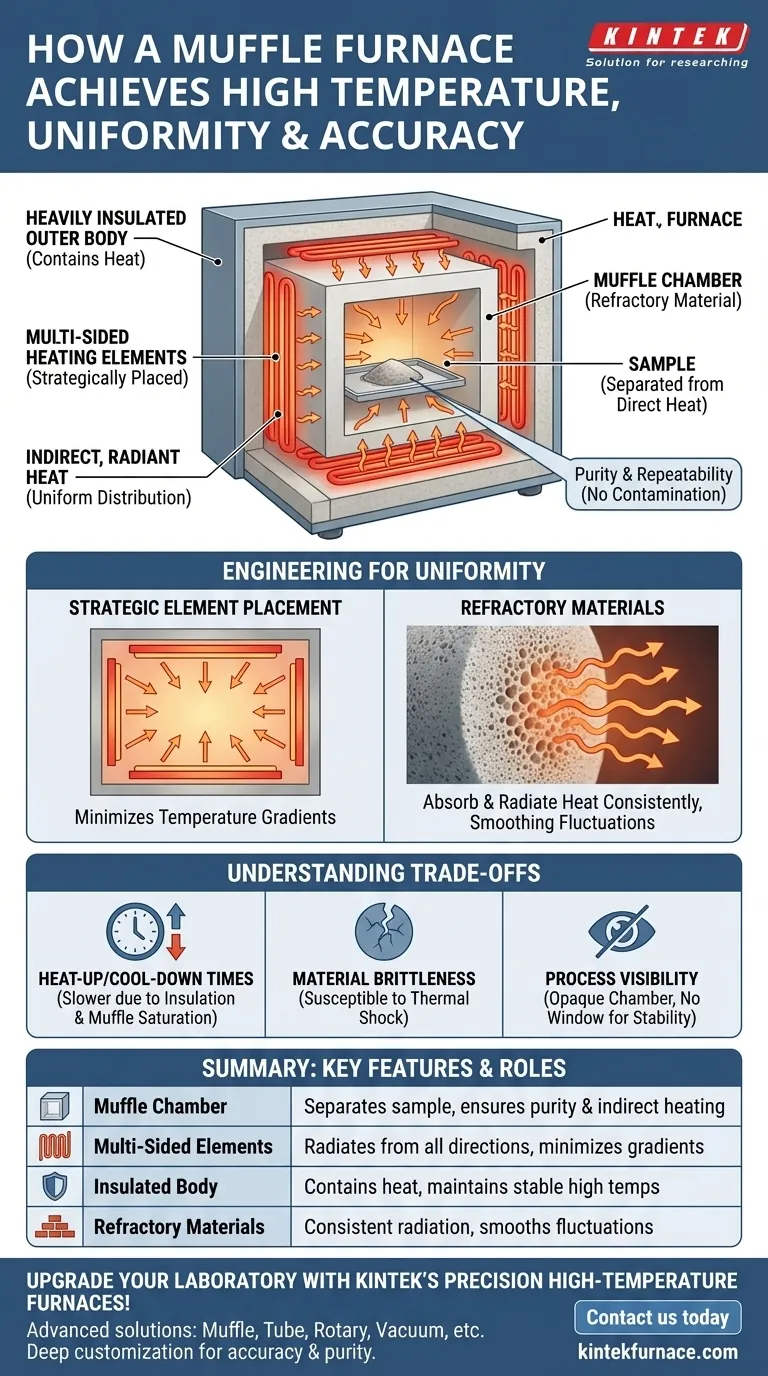

In essence, a muffle furnace achieves its high temperature, uniformity, and accuracy through three core design principles. It uses a heavily insulated outer body to contain heat, an inner chamber (the "muffle") to separate the sample from the direct heating elements, and strategically placed elements to distribute thermal energy evenly. This combination ensures the sample is heated by consistent, radiant heat in a controlled, uncontaminated environment.

The defining feature is not just high heat, but controlled heat. The muffle acts as a protective barrier, ensuring the sample is heated indirectly and uniformly, which is the key to achieving accurate and repeatable results without contamination.

The Core Principle: Indirect Heating via the Muffle

The name "muffle furnace" directly describes its primary mechanism. The process relies on an inner chamber, or muffle, to create a highly controlled heating environment.

What is a "Muffle"?

A muffle is a sealed chamber, typically made of high-temperature refractory ceramics like alumina. This chamber sits inside the furnace's insulated outer body and houses the material being processed.

Crucially, the heating elements are located outside of this muffle.

Separating the Sample from the Heat Source

This separation is the most critical aspect of the design. The heating elements heat the muffle chamber, and the chamber itself then radiates that heat evenly onto the sample inside.

This indirect heating prevents contamination from combustion byproducts or flaking from the elements themselves, which is essential for sensitive processes like elemental analysis or ashing.

Protecting the Heating Elements

The muffle also works in reverse, protecting the heating elements. It shields them from any corrosive fumes or byproducts released from the sample during the heating process, significantly extending the life and reliability of the furnace.

Engineering for Temperature Uniformity

Achieving a uniform temperature across the entire sample is a primary design goal. Several features work together to eliminate the hot and cold spots that can ruin a process.

Strategic Placement of Heating Elements

Modern muffle furnaces do not rely on a single heat source. Instead, they feature open coil heating elements on multiple sides of the chamber (often both sides and sometimes the top and bottom).

This multi-sided approach ensures that heat radiates toward the center from all directions, minimizing any potential temperature gradient across the chamber.

The Role of Chamber Materials

The refractory materials used to build the muffle are chosen for their ability to withstand extreme thermal cycling. More importantly, they absorb and radiate heat very effectively and consistently.

This property helps smooth out any minor fluctuations from the heating elements, ensuring the chamber walls provide a perfectly even field of radiant heat.

Eliminating Hot and Cold Spots

The combination of indirect heating and multi-sided elements ensures the sample at the back of the furnace experiences the same temperature as the sample at the front. This is non-negotiable for applications where consistency is paramount.

Understanding the Trade-offs

While highly effective, the muffle furnace design is not without its inherent trade-offs. Understanding these limitations is key to using the equipment properly.

Heat-Up and Cool-Down Times

Because the heat must first saturate the muffle chamber before reaching the sample, heat-up times can be slightly slower compared to direct-heating ovens. The massive insulation also means they retain heat and can take longer to cool down.

Material Brittleness

The ceramic materials that make an excellent muffle are often brittle. They are highly susceptible to thermal shock—cracking caused by rapid, uneven temperature changes. Users must avoid placing very cold items into a hot furnace.

Process Visibility

By design, the sample is enclosed within an opaque chamber. Most muffle furnaces lack a window, meaning you cannot visually monitor the process without opening the door, which drastically impacts temperature stability.

Making the Right Choice for Your Goal

A muffle furnace is a specialized tool. Its value depends entirely on the requirements of your process.

- If your primary focus is process purity and avoiding contamination: The muffle's separation of the sample from the heat source is its most valuable feature.

- If your primary focus is absolute temperature uniformity for sensitive materials: The combination of indirect, radiant heat and multi-sided elements makes a muffle furnace the superior choice.

- If your primary focus is simply high-temperature heating without strict purity needs: A simpler, direct-heat furnace or kiln might be a more cost-effective solution.

Ultimately, a muffle furnace is the definitive choice when accuracy, purity, and repeatability are more important than speed.

Summary Table:

| Feature | Role in Achieving High Temperature, Uniformity, and Accuracy |

|---|---|

| Muffle Chamber | Separates sample from heating elements for indirect, radiant heating, ensuring purity and uniform heat distribution. |

| Multi-Sided Heating Elements | Placed strategically to radiate heat from all directions, minimizing temperature gradients across the chamber. |

| Insulated Outer Body | Contains heat effectively, maintaining stable high temperatures and improving energy efficiency. |

| Refractory Materials | Absorb and radiate heat consistently, smoothing fluctuations and enhancing temperature uniformity. |

Upgrade your laboratory with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met with accuracy and purity. Contact us today to discuss how our furnaces can enhance your process efficiency and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment