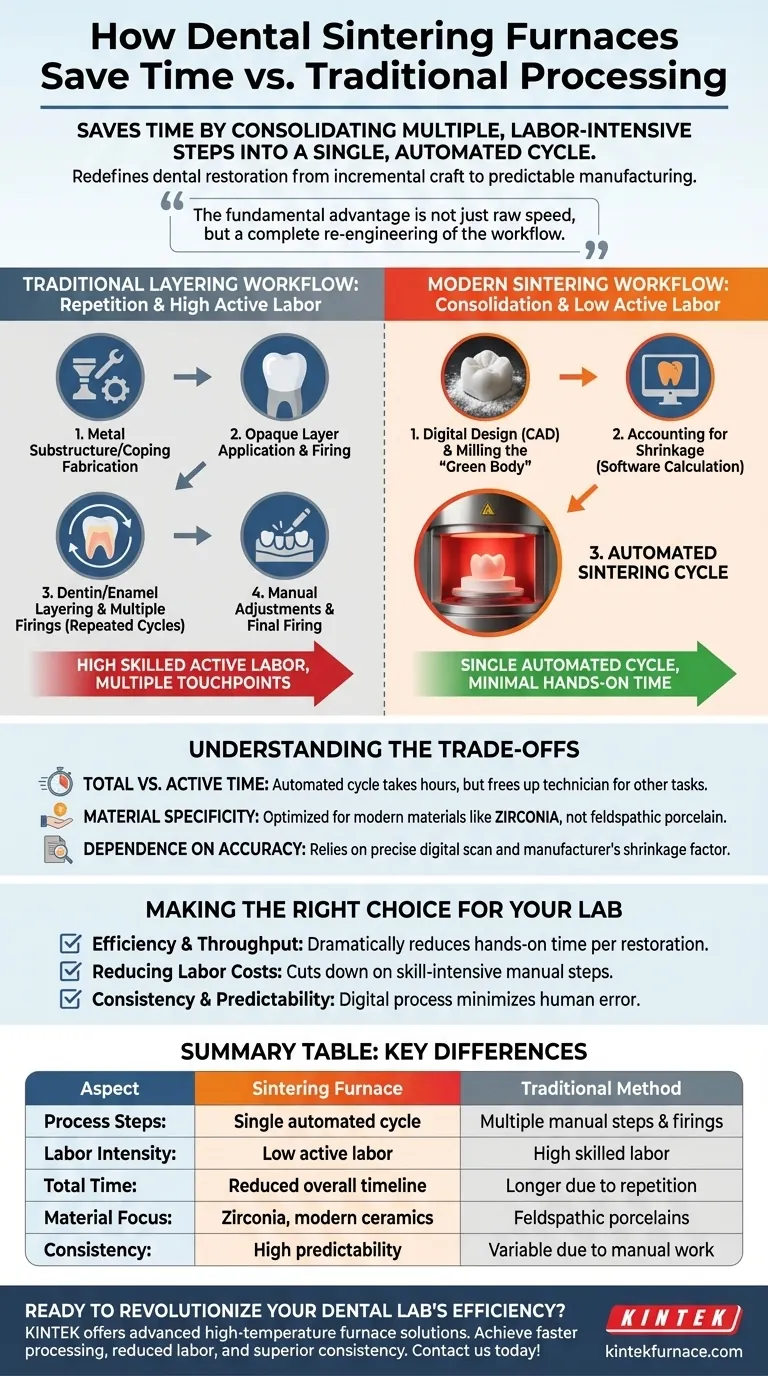

At its core, a dental sintering furnace saves time by consolidating multiple, labor-intensive ceramic processing steps into a single, automated cycle. Unlike traditional methods that require manual layering and repeated firings, sintering automates the process of transforming a soft, milled restoration into its final, high-strength state, significantly reducing active labor and the overall production timeline.

The fundamental time-saving advantage of sintering is not just raw speed, but a complete re-engineering of the dental restoration workflow. It replaces the incremental, manual artistry of traditional porcelain application with a predictable, digitized manufacturing process that minimizes hands-on time and potential for human error.

The Sintering Process vs. Traditional Methods

To understand the time savings, we must contrast the modern sintering workflow with the traditional one it often replaces, such as for porcelain-fused-to-metal (PFM) crowns.

The Modern Sintering Workflow: Consolidation

A modern workflow with a sintering furnace is characterized by digitization and automation.

Milling the "Green Body"

The process begins with a digital design (CAD) that is sent to a milling machine. The machine carves the restoration out of a block of pre-sintered zirconia or a similar material. This initial, chalk-like form is called a green body.

Accounting for Shrinkage

The green body is intentionally milled larger than the final restoration. This is because the sintering process will condense the material, causing predictable shrinkage. Software automatically calculates this, ensuring the final product is the precise size and shape required.

The Automated Sintering Cycle

The milled green body is placed in the sintering furnace. The furnace then executes a precise, pre-programmed heating cycle, raising the temperature to just below the material's melting point. This single, unattended cycle hardens and densifies the restoration to its final strength.

The Traditional Layering Workflow: Repetition

The traditional method for creating a PFM crown is a sequential, manual process requiring multiple steps and a high degree of technical skill.

Creating the Substructure

First, a metal substructure or coping that fits the tooth preparation must be fabricated. This is a multi-step process in itself.

Opaque and Layering

A technician then manually applies an opaque layer of porcelain to the metal to mask its color and fires it in a furnace. Following this, they painstakingly apply multiple layers of dentin and enamel-colored porcelain powders to build up the tooth's anatomy, with each layer requiring a separate firing cycle in the furnace.

Multiple Firings and Manual Adjustments

This process of applying material, firing, cooling, and making adjustments is repeated until the desired shape and shade are achieved. Each step requires direct, skilled labor and introduces a potential point of failure.

Understanding the Trade-offs

While the time savings are significant, it is critical to understand the context and limitations of the sintering process.

Total Cycle Time vs. Active Labor Time

The most significant saving is in active labor time. While a sintering cycle itself can take several hours, it is almost entirely automated. A technician can place the restoration in the furnace and perform other tasks, whereas traditional layering requires their constant, focused attention.

Material Specificity

Sintering furnaces are designed for specific materials, most notably zirconia. This material offers exceptional strength but may have different aesthetic properties than traditional feldspathic porcelains. The choice to adopt a sintering workflow is also a choice to focus on these modern materials.

Dependence on Accuracy

The entire process relies on the precision of the initial digital scan, the design software, and the manufacturer's stated shrinkage factor for the material. Any error in these initial inputs will result in a poorly fitting restoration, as there is no opportunity for manual adjustment during the sintering phase.

Making the Right Choice for Your Lab

Adopting a sintering furnace is a strategic decision that fundamentally alters your production capabilities.

- If your primary focus is efficiency and throughput: A sintering workflow is the clear choice. It dramatically reduces the hands-on time per restoration, allowing you to produce more units with the same amount of staff.

- If your primary focus is reducing labor costs: Automating the hardening and densification process directly cuts down on the most time-consuming and skill-intensive part of traditional ceramic work.

- If your primary focus is consistency and predictability: The digital nature of the sintering workflow removes much of the variability inherent in a manual process, leading to more predictable results and fewer remakes.

Ultimately, integrating a dental sintering furnace transforms the creation of high-strength restorations from a multi-stage craft into a streamlined and highly efficient manufacturing process.

Summary Table:

| Aspect | Sintering Furnace | Traditional Method |

|---|---|---|

| Process Steps | Single automated cycle | Multiple manual steps and firings |

| Labor Intensity | Low active labor | High skilled labor |

| Total Time | Reduced overall timeline | Longer due to repetition |

| Material Focus | Zirconia and modern ceramics | Feldspathic porcelains |

| Consistency | High predictability | Variable due to manual work |

Ready to revolutionize your dental lab's efficiency?

At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for diverse laboratory needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing. With our strong deep customization capability, we can precisely meet your unique experimental requirements, ensuring you achieve faster processing times, reduced labor costs, and superior consistency in restorations like zirconia crowns.

Don't let outdated methods slow you down—contact us today to learn how our sintering furnaces can transform your workflow and boost productivity!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations