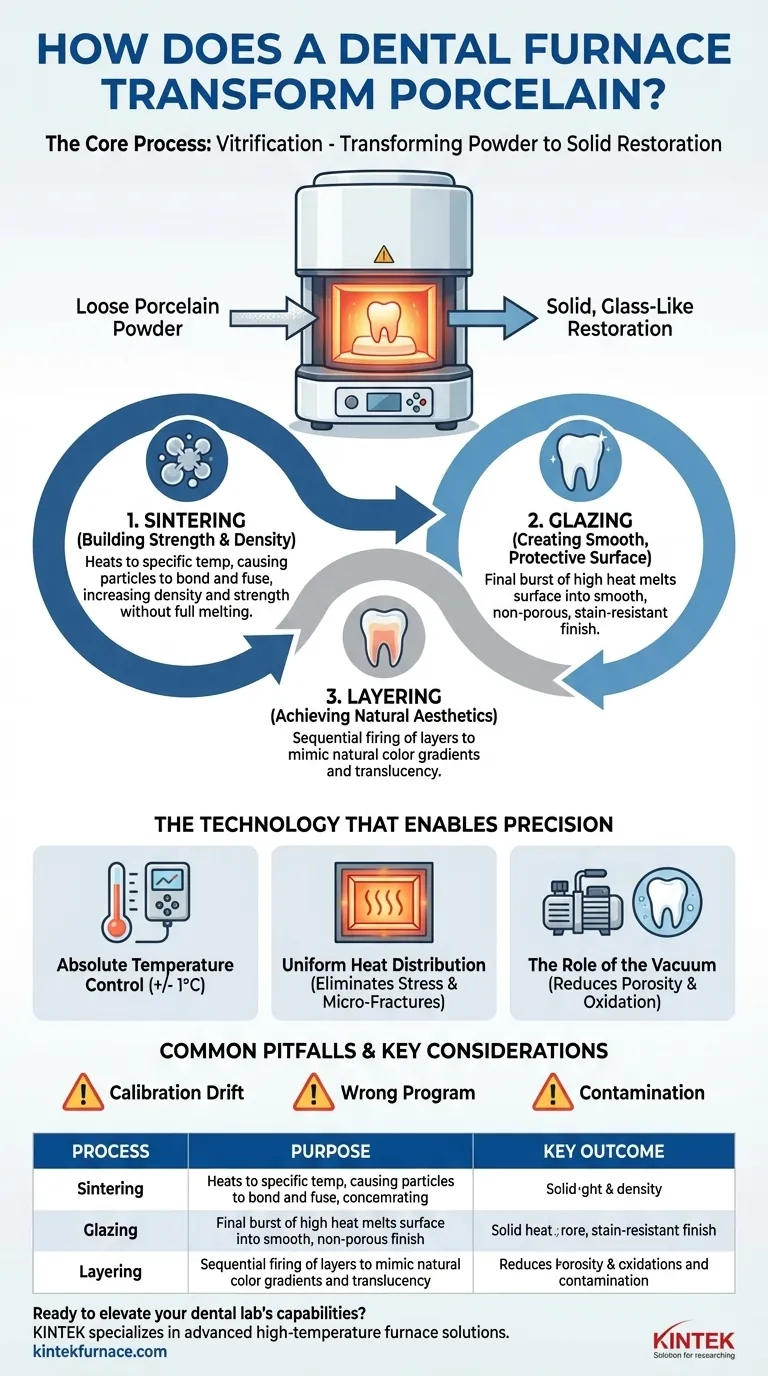

At its core, a dental furnace transforms loose porcelain powder into a solid, glass-like restoration through a highly controlled heating process known as vitrification. This transformation is not simple heating; it is a precise, multi-stage procedure that fuses ceramic particles at a molecular level to create a final product with the necessary strength, fit, and aesthetic qualities of a natural tooth.

A dental furnace is not merely an oven. It is a precision instrument designed to execute specific thermal programs that control the sintering, glazing, and layering of porcelain, ensuring the final restoration is both durable and indistinguishable from natural dentition.

The Three Critical Transformations in a Dental Furnace

To understand how a furnace works, you must understand the three distinct processes it facilitates. Each step serves a unique purpose in converting raw material into a final, functional restoration.

Sintering: Building Strength and Density

Sintering is the primary hardening process. The furnace heats the porcelain to a specific temperature, causing the individual particles to bond and fuse together without fully melting.

This process dramatically increases the material's density and strength. Precise control over the heating rate and final temperature is critical to ensure complete fusion without causing distortion or defects.

Glazing: Creating a Smooth, Protective Surface

After the restoration has its core strength from sintering, the furnace performs a glazing cycle. This involves applying a final, quick burst of high heat.

This cycle melts the surface layer into a smooth, non-porous, and glossy finish. A glazed surface is not only aesthetically pleasing but also stain-resistant, easy to clean, and gentle on opposing teeth.

Layering: Achieving Natural Aesthetics

High-end restorations are not monolithic; they are built in layers to mimic the translucency and color variations of a natural tooth.

A programmable furnace allows technicians to fire each layer of porcelain separately. This controlled, sequential firing is essential for developing the depth, color gradients, and lifelike appearance required for superior cosmetic results.

The Technology That Enables Precision

The transformative power of a dental furnace comes from its advanced technical features, which work in concert to ensure predictable, high-quality outcomes.

Absolute Temperature Control

Modern furnaces offer exceptional thermal accuracy, often maintaining a temperature within +/- 1°C of the target. This is achieved through multi-segment programmable digital controllers.

This precision is non-negotiable for preventing overheating, which can cause slumping, or under-firing, which results in a weak, porous structure.

Uniform Heat Distribution

The furnace's muffle, or heating chamber, is engineered to provide a uniform heating zone. This ensures that every part of the restoration, regardless of its position, receives the exact same thermal exposure.

Uneven heating is a primary cause of internal stress and micro-fractures, which can lead to premature failure of the restoration in the patient's mouth.

The Role of the Vacuum

Many advanced firing cycles are performed under a vacuum. The furnace pumps air out of the muffle before and during the heating process.

This vacuum environment significantly reduces the risk of air bubbles being trapped within the porcelain and prevents oxidation or contamination of the material. The result is a purer, denser, and stronger final product with enhanced aesthetic clarity.

Common Pitfalls and Key Considerations

While modern furnaces are highly automated, achieving optimal results requires an understanding of their operational nuances and limitations.

The Importance of Calibration

A furnace's precision is only as reliable as its last calibration. Temperature sensors can drift over time, leading to inaccurate firing cycles that compromise the quality of the work. Regular calibration is essential for consistent, high-quality output.

Program Suitability

Using the wrong firing program for a specific porcelain material is a common source of failure. Each ceramic system has unique temperature and timing requirements provided by the manufacturer. Blindly using a generic program will yield unpredictable results.

The Impact of Contamination

The firing chamber must be kept impeccably clean. Any debris, from previous restorations or other sources, can vaporize during a cycle and become embedded in the new restoration, causing discoloration and structural weak points.

Making the Right Choice for Your Goal

Understanding the core functions of a dental furnace empowers you to select and utilize the right technology for your specific clinical or laboratory objectives.

- If your primary focus is high-volume, standardized restorations: Prioritize a furnace with robust program storage, automatic temperature adjustment, and a durable, low-maintenance design for consistent throughput.

- If your primary focus is highly customized, complex aesthetic work: You need a furnace with a multi-segment programmable controller, excellent vacuum performance, and precise layering capabilities.

- If your primary focus is maximizing material strength and purity: A model with a deep and rapid vacuum system is non-negotiable to eliminate porosity and contamination.

Ultimately, mastering the use of a dental furnace is about translating technical knowledge into predictable, high-quality outcomes for every patient.

Summary Table:

| Process | Purpose | Key Outcome |

|---|---|---|

| Sintering | Fuses porcelain particles | Increases strength and density |

| Glazing | Melts surface layer | Creates smooth, protective finish |

| Layering | Fires multiple porcelain layers | Achieves natural aesthetics and color depth |

Ready to elevate your dental lab's capabilities? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique needs for sintering, glazing, and layering porcelain. Whether you're focused on high-volume production or complex aesthetic work, our furnaces ensure durable, high-quality restorations. Contact us today to discuss how we can enhance your workflow and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab