At its core, a controlled atmosphere furnace achieves energy efficiency by preventing waste. Unlike less advanced systems, these furnaces are engineered to solve the three fundamental challenges of thermal processing: they keep heat from escaping, they apply that heat with extreme precision, and they complete the process faster. This combination of superior insulation, accurate control systems, and rapid, uniform heating directly translates into lower energy consumption and reduced operational costs.

While their primary purpose is to control a material's processing environment, controlled atmosphere furnaces are inherently designed for efficiency. Their advanced insulation, precise controls, and uniform heating don't just improve product quality—they systematically eliminate the primary sources of energy waste found in traditional systems.

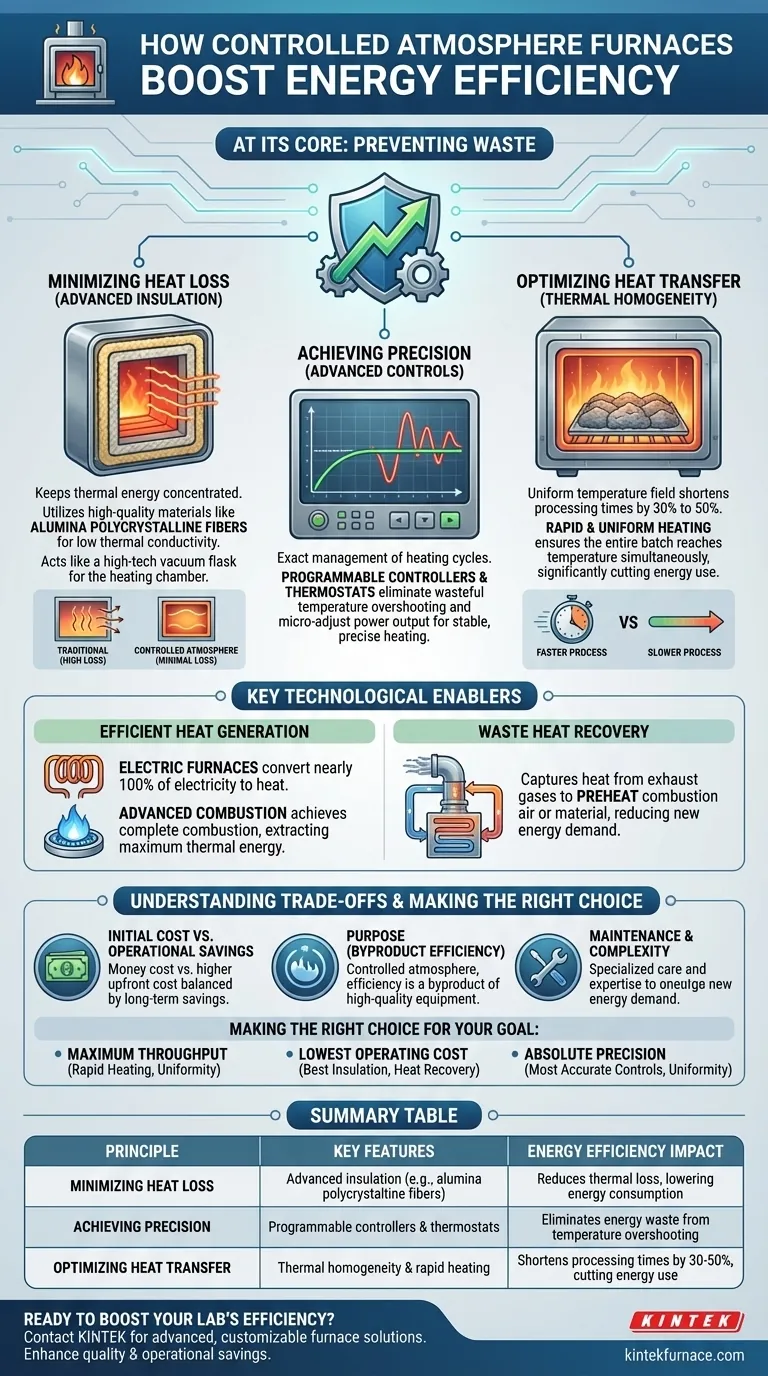

The Core Principles of Energy Efficiency

A furnace's efficiency isn't the result of a single feature, but an integrated system designed to minimize thermal loss at every stage.

Minimizing Heat Loss with Advanced Insulation

The most straightforward way to waste energy is to let heat escape. Modern controlled atmosphere furnaces are built to prevent this.

They utilize high-quality insulation materials, such as alumina polycrystalline fibers, which have exceptionally low thermal conductivity. This advanced insulation acts as a barrier, keeping thermal energy concentrated within the heating chamber where it is needed.

This principle is the difference between holding hot coffee in a paper cup versus a high-tech vacuum flask. The flask's superior insulation keeps the contents hot for hours with no additional energy input, which is precisely what furnace insulation does for the heating chamber.

Achieving Precision with Advanced Control Systems

Wasted energy also comes from imprecise control. Overshooting a target temperature and then waiting for it to cool down consumes excess energy and time.

Controlled atmosphere furnaces integrate programmable controllers and thermostats that allow for exact management of the heating cycle. These systems monitor the temperature continuously and make micro-adjustments to the power output.

This ensures the furnace only uses the precise amount of energy required to reach and maintain the setpoint, eliminating the wasteful peaks and valleys of less sophisticated controls.

Optimizing Heat Transfer with Thermal Homogeneity

If a workload heats unevenly, the entire process must be extended to ensure the coldest spot eventually reaches the target temperature. This "soaking" time is pure energy waste.

These furnaces are designed for thermal homogeneity, meaning they create an extremely uniform temperature field throughout the chamber.

Rapid and uniform heating ensures that the entire material or batch of parts reaches the desired temperature at virtually the same time. This can shorten processing times by 30% to 50%, representing a direct and significant reduction in total energy consumption.

Key Technological Enablers

Beyond the core principles, specific technologies contribute directly to lower energy use.

Efficient Heat Generation

How the heat is created in the first place is fundamental. Electric furnaces are a prime example, converting nearly 100% of the electricity they draw directly into usable heat.

For fuel-fired models, efficiency comes from advanced combustion technology. These systems are designed to achieve complete combustion, extracting the maximum possible thermal energy from the fuel source with minimal waste.

Waste Heat Recovery

In many industrial processes, hot exhaust or flue gases are simply vented into the atmosphere, carrying valuable thermal energy with them.

More advanced furnace systems incorporate heat recovery mechanisms. These components capture heat from the flue gases and use it to preheat combustion air or the material load, reducing the amount of new energy needed to run the next cycle.

Understanding the Trade-offs

While highly efficient, these furnaces present considerations that are critical for making an informed decision.

Initial Cost vs. Operational Savings

The advanced materials and sophisticated control systems that enable high efficiency come at a price. The initial capital investment for a controlled atmosphere furnace is typically higher than for a conventional furnace.

However, this upfront cost is balanced by significant long-term savings in energy consumption. The reduction in operational costs can lead to a compelling return on investment over the furnace's lifespan.

The Purpose of the Controlled Atmosphere

It is crucial to understand that the atmosphere control itself (e.g., using nitrogen or argon) is for the process, not for energy savings. The energy efficiency is a byproduct of the high-quality equipment required to perform such a precise process.

You invest in a controlled atmosphere furnace for its ability to prevent oxidation and ensure material integrity. The fact that it is also highly energy-efficient is a powerful secondary benefit driven by its design.

Maintenance and Complexity

Sophisticated systems require sophisticated care. The precision controls and specialized components may require more specialized maintenance schedules and technician expertise compared to simpler, less efficient furnaces.

Making the Right Choice for Your Goal

Selecting the right furnace depends on your primary operational driver.

- If your primary focus is maximum throughput: Prioritize furnaces that advertise rapid heating rates and proven thermal homogeneity, as shortening cycle time is your most direct path to efficiency.

- If your primary focus is the lowest operating cost: Look for models with the best insulation packages, waste heat recovery options, and highly programmable controllers to minimize energy use during every cycle.

- If your primary focus is absolute process precision: Choose the furnace with the most accurate temperature controls and uniformity, as the energy efficiency gains will naturally follow from a system that wastes no energy on imprecision.

Ultimately, investing in a furnace with superior thermal management is an investment in both process quality and long-term energy efficiency.

Summary Table:

| Principle | Key Features | Energy Efficiency Impact |

|---|---|---|

| Minimizing Heat Loss | Advanced insulation (e.g., alumina polycrystalline fibers) | Reduces thermal loss, lowering energy consumption |

| Achieving Precision | Programmable controllers and thermostats | Eliminates energy waste from temperature overshooting |

| Optimizing Heat Transfer | Thermal homogeneity and rapid heating | Shortens processing times by 30-50%, cutting energy use |

Ready to boost your lab's energy efficiency and cut costs? KINTEK provides advanced high-temperature furnace solutions, including Controlled Atmosphere Furnaces, tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization for precise experimental requirements. Contact us today to learn how our products can enhance your process quality and operational savings!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process