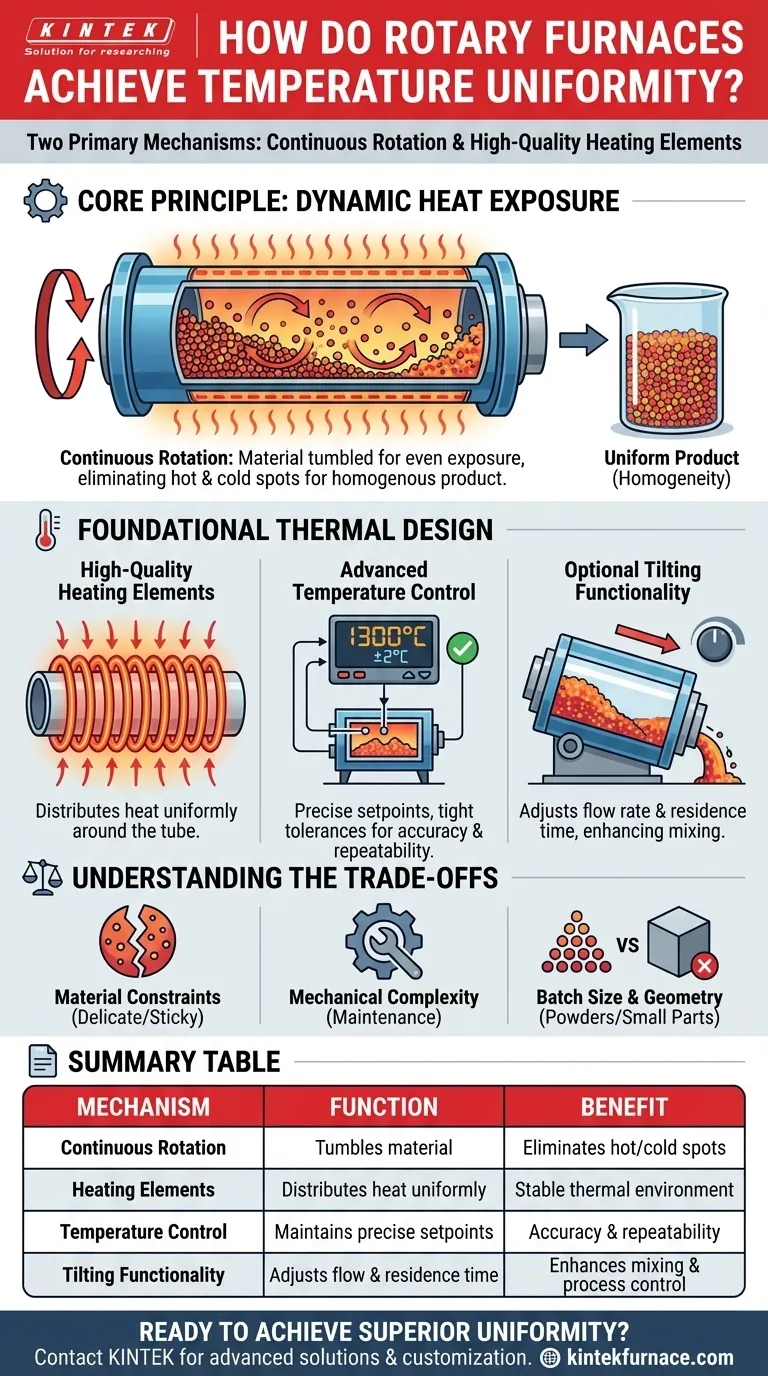

In essence, rotary furnaces achieve superior temperature uniformity through two primary mechanisms: the continuous rotation of the furnace tube and the strategic placement of high-quality heating elements. The rotation ensures every surface of the material is constantly and evenly exposed to the heat source, while the advanced heating elements and control systems create a stable and consistent thermal environment.

The core advantage of a rotary furnace is its use of mechanical motion to solve a thermal problem. Instead of relying on passive heat radiation alone, it actively tumbles the material, systematically eliminating hot and cold spots to guarantee a level of homogeneity that is difficult to achieve in static systems.

The Core Principle: Dynamic Heat Exposure

A rotary furnace's design fundamentally changes how thermal energy is transferred to the material being processed. It moves from a static, one-sided exposure to a dynamic, all-encompassing one.

The Role of Continuous Rotation

The central component, the furnace tube, rotates 360 degrees, typically driven by a motor. This constant tumbling or rolling motion is the most critical factor for uniformity.

As the tube turns, it continuously lifts and redistributes the material inside. This ensures that no single portion of the material remains in one place for too long.

Preventing Localized Overheating

In a static furnace, material at the bottom or sides can become superheated while material in the center remains cooler. Rotation prevents this entirely.

This active mixing promotes consistent and complete chemical reactions or phase changes, from sintering powders to calcining compounds.

The Impact on Material Homogeneity

The end result of uniform heating is a uniform product. This homogeneity is critical in applications like advanced ceramics, battery materials, and catalysts, where even minor inconsistencies can lead to component failure or reduced performance.

Foundational Thermal Design

While rotation is the active component, it works in concert with a precisely engineered thermal system. The quality of this underlying system sets the baseline for the furnace's performance.

High-Quality Heating Elements

Uniformity begins at the source. Rotary furnaces use high-quality heating elements designed for even heat distribution around the entire circumference of the process tube.

This creates a stable and predictable heat zone, which is the foundation upon which the rotational mechanism can achieve its goal.

Advanced Temperature Control

Modern rotary furnaces feature precise digital and programmable control systems. These controllers continuously monitor the chamber and adjust power to the heating elements to maintain the setpoint with extreme accuracy.

Control tolerances can be as tight as +/- 2°C, even at very high temperatures (e.g., 1300°C), ensuring that experimental or production runs are both accurate and repeatable.

Optional Tilting Functionality

Some furnaces add a tilting mechanism to the furnace body. This allows the operator to control the residence time and flow rate of material through the tube, adding another layer of process control that further enhances mixing and uniform treatment.

Understanding the Trade-offs

While exceptional for uniformity, the rotary design is not universally applicable. Understanding its limitations is key to making an informed decision.

Material Constraints

The tumbling action that ensures uniformity can be a drawback for certain materials. Friable or delicate materials may be damaged, and sticky or agglomerating powders may not flow properly.

Mechanical Complexity

The addition of a motor, drive system, and rotating seals introduces mechanical complexity not present in a simple box or muffle furnace. These moving parts require regular maintenance and can be points of failure.

Batch Size and Geometry

Rotary furnaces are ideal for powders, granules, and small parts. They are inherently unsuitable for processing large, singular components or objects that cannot be tumbled.

Making the Right Choice for Your Goal

Selecting the correct furnace type depends entirely on the nature of your material and your processing objective.

- If your primary focus is producing highly homogeneous powders or granules: A rotary tube furnace is the superior choice due to its active mixing capability.

- If your primary focus is continuous or semi-continuous processing: The design of a rotary furnace is perfectly suited for a constant flow of material.

- If your primary focus is heat-treating large, static, or delicate objects: A traditional muffle or box furnace with excellent static temperature uniformity would be a more appropriate solution.

Ultimately, the decision rests on matching the furnace's heating method to the physical requirements of your material and process.

Summary Table:

| Mechanism | Function | Benefit |

|---|---|---|

| Continuous Rotation | Tumbles material for even heat exposure | Eliminates hot and cold spots |

| Heating Elements | Distributes heat uniformly around the tube | Provides stable thermal environment |

| Temperature Control | Maintains precise setpoints with tight tolerances | Ensures accuracy and repeatability |

| Tilting Functionality | Adjusts material flow and residence time | Enhances mixing and process control |

Ready to achieve superior temperature uniformity in your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements for powders, granules, and small parts. Contact us today to discuss how our rotary furnaces can enhance your material homogeneity and efficiency!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating