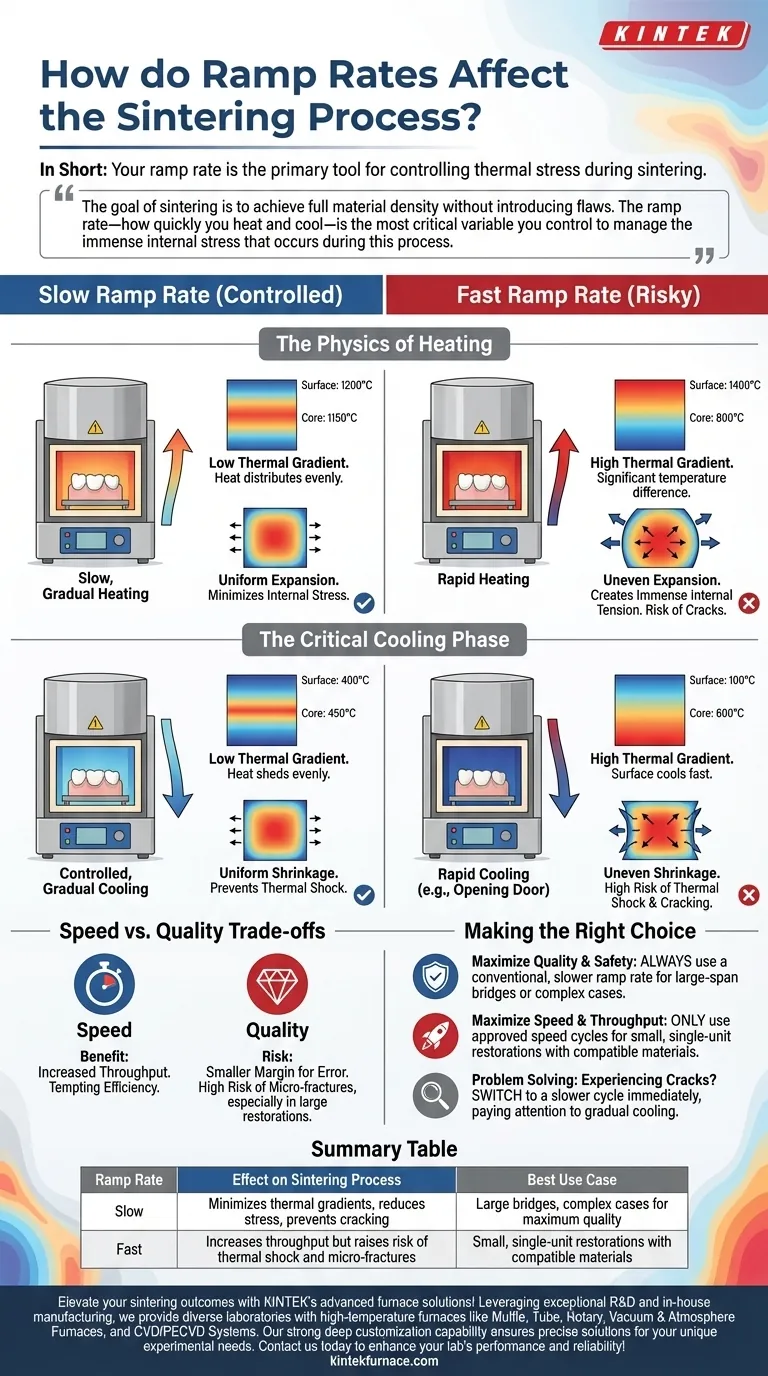

In short, your ramp rate is the primary tool for controlling thermal stress during sintering. A slow, gradual rate of heating and cooling allows thermal energy to distribute evenly throughout the restoration, minimizing internal stress and preventing the formation of cracks. Conversely, a rapid ramp rate creates a significant temperature difference between the surface and the core, introducing stress that can compromise the final integrity of the workpiece.

The goal of sintering is to achieve full material density without introducing flaws. The ramp rate—how quickly you heat and cool—is the most critical variable you control to manage the immense internal stress that occurs during this process, directly impacting the final strength and success of the restoration.

The Physics of Heating and Stress

The fundamental challenge in sintering is managing how a solid object responds to a rapid change in temperature. This is governed by basic principles of heat transfer and material science.

The Problem of Temperature Gradients

When a furnace begins to heat, the outer surface of the restoration heats up first. The interior, or core, lags behind.

This difference in temperature between the surface and the core is known as a thermal gradient.

How Gradients Create Stress

As the zirconia heats, it expands. If the surface is significantly hotter than the core, it tries to expand more than the still-cool interior will allow.

This conflict between the expanding surface and the stable core creates immense internal tension. If this stress exceeds the material's strength in its pre-sintered ("green") state, microscopic or even macroscopic cracks will form.

Why a Slow Ramp Rate Works

A slow ramp rate gives heat time to conduct from the surface to the core of the restoration.

This keeps the thermal gradient low, ensuring the entire unit heats up and expands more uniformly. This drastically reduces internal stress and is the safest way to prevent cracking.

The Critical Cooling Phase

The risk of thermal damage is just as high during cooling as it is during heating, and it is often the most overlooked part of the process.

Cooling is Heating in Reverse

As the furnace cools, the surface of the restoration sheds heat and begins to shrink faster than the still-hot interior.

This creates another thermal gradient and a new set of internal stresses. The shrinking exterior is now pulling against an expanded core, once again creating tension.

The Danger of Thermal Shock

Rapid cooling is the primary cause of thermal shock. This occurs when the temperature difference is so great that the resulting stress instantly causes the material to crack.

Opening the furnace door too early to speed up cooling is a common cause of this type of failure. A controlled, gradual cooling ramp is essential for the restoration to shrink uniformly.

Understanding the Trade-offs: Speed vs. Quality

In any production environment, time is a critical factor. This creates a natural tension between the speed of the sintering cycle and the quality of the outcome.

The Lure of Fast Sintering

The clear benefit of a fast ramp rate is speed. Speed-sintering cycles can dramatically increase a lab's daily throughput, allowing more cases to be completed.

These cycles are tempting for their efficiency, but they operate with a much smaller margin for error.

The Inherent Risk of Speed

A fast ramp rate, by definition, maximizes the thermal gradient. While modern zirconia materials and furnaces are better engineered to withstand this, the risk of inducing stress and micro-fractures is inherently higher.

This risk is magnified with thicker restorations or large-span bridges, where the thermal gradient will be even more pronounced.

When Slower is Non-Negotiable

For larger, multi-unit restorations, a slow, conventional ramp rate is the only way to reliably mitigate risk.

The greater the mass of the zirconia, the longer it takes for heat to penetrate evenly. Using a fast cycle on a large bridge almost guarantees a significant thermal gradient and a high probability of failure.

Making the Right Choice for Your Goal

Your decision on ramp rate should be a deliberate one based on the restoration's characteristics and your operational priorities.

- If your primary focus is maximum quality and safety: Always use a conventional, slower ramp rate, especially for large-span bridges or complex, high-value anterior cases.

- If your primary focus is speed and throughput: Only use manufacturer-approved speed cycles with compatible zirconia, and restrict them to smaller, single-unit restorations where the risk of large thermal gradients is lowest.

- If you are experiencing unexplained cracking or chipping: Your ramp rate is the first variable to investigate. Immediately switch to a slower cycle, paying special attention to a gradual cooling phase, to see if the issue resolves.

Ultimately, controlling your ramp rate is about managing risk to ensure predictable, high-strength, and aesthetic outcomes for every case.

Summary Table:

| Ramp Rate | Effect on Sintering Process | Best Use Case |

|---|---|---|

| Slow | Minimizes thermal gradients, reduces stress, prevents cracking | Large bridges, complex cases for maximum quality |

| Fast | Increases throughput but raises risk of thermal shock and micro-fractures | Small, single-unit restorations with compatible materials |

Elevate your sintering outcomes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, helping you achieve superior thermal control and flawless restorations. Contact us today to discuss how we can enhance your lab's performance and reliability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations